A double-spindle turning-milling compound machine tool with inclined bed

A compound machine tool and double-spindle technology, applied in the field of CNC machine tools, can solve the problems of inability to automate two-end processing, achieve the effect of reducing production auxiliary time, reducing manufacturing cycle and waiting time, and having a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

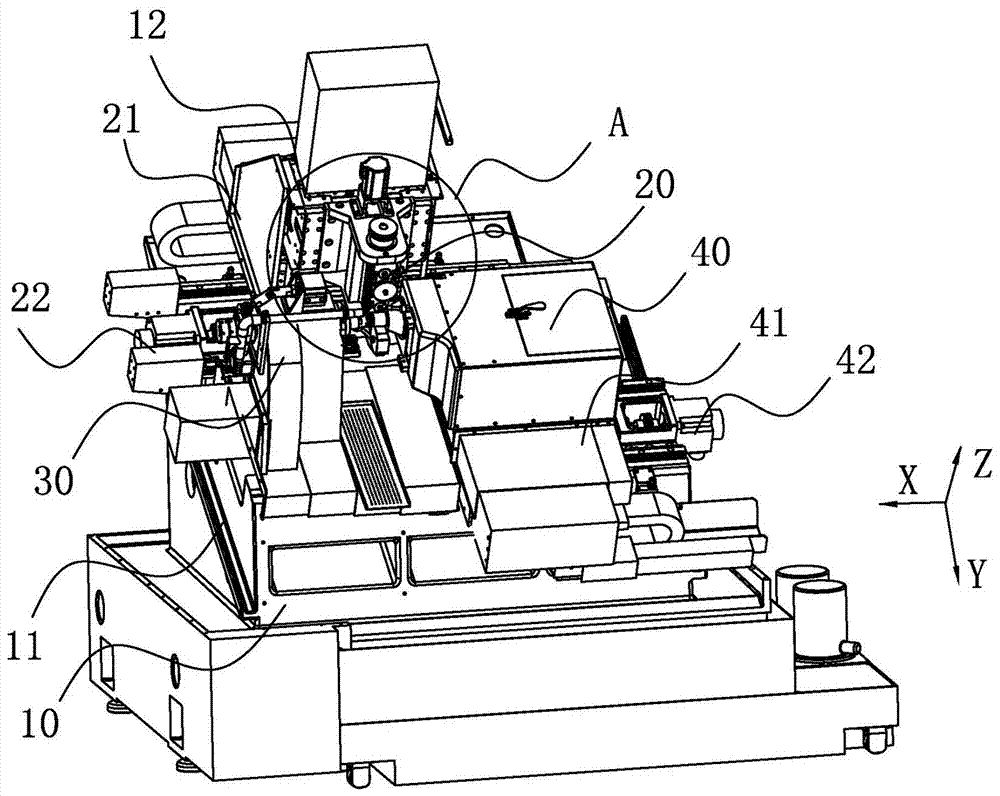

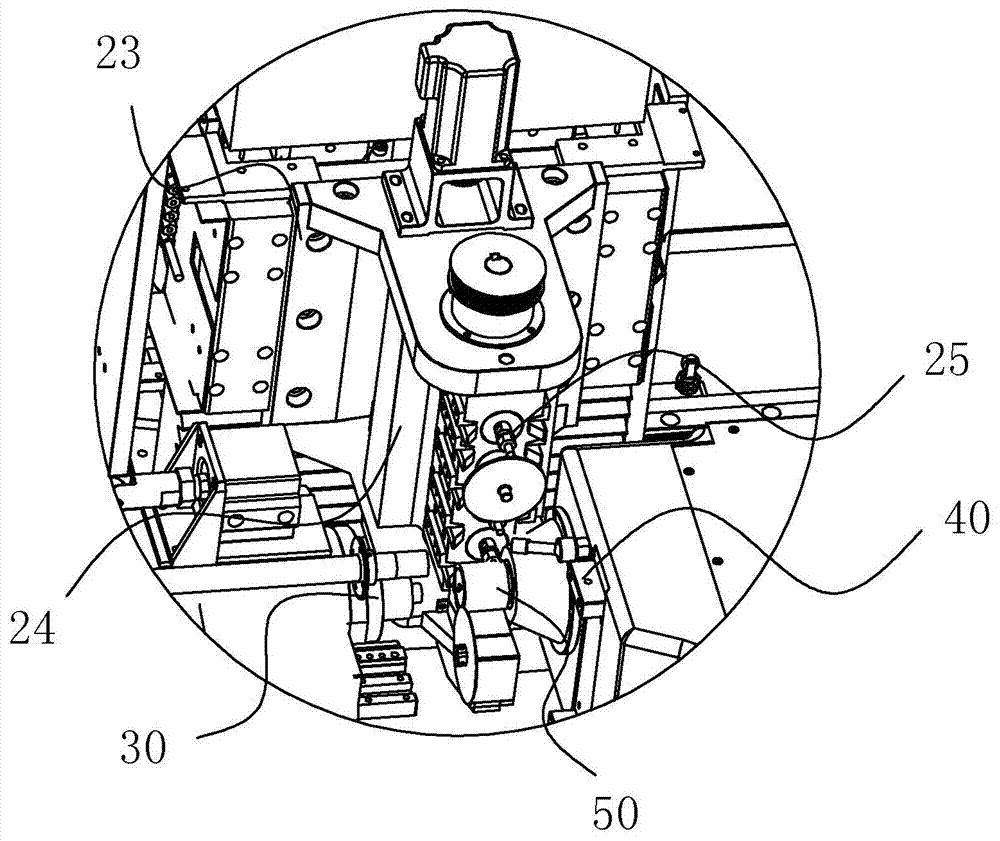

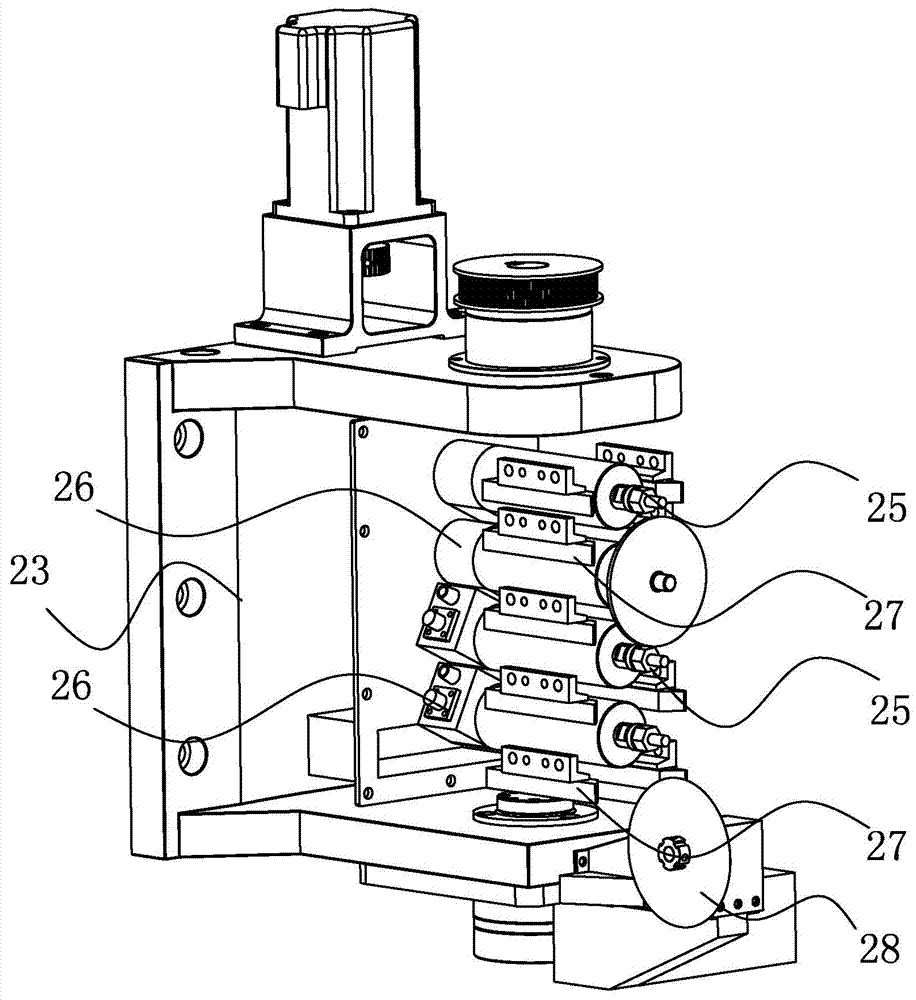

[0033] Such as Figure 1 to Figure 3 As shown, a kind of slanted bed dual-spindle turning-milling compound machine tool described in the present application includes a machine base 10, the upper part of the machine base 10 is inclined to set the bed 11, and the machine base 10 is provided with a power head 20 capable of changing the direction. The head 20 can rotate at any angle around an axis perpendicular to the bed 11 of the machine base 10 and can be fixed at a desired angle. Both sides of the power head 20 are respectively provided with a main shaft clamping device 30 and a sub shaft clamping device 40, the main shaft clamping device 30 and the sub shaft clamping device 40 are arranged oppositely, and the axis center of the main shaft clamping device 30 and the sub shaft mounting The axis center of the clamping device 40 is the same distance from the bed 11 of the machine base 10, the power head 20 can mill the side and end face of the workpiece on the main shaft clamping...

Embodiment 2

[0038] The main structure and principle of this embodiment are the same as those of Embodiment 1, and will not be repeated here. The difference from Embodiment 1 is:

[0039] The power head is a non-rotatable power head (not shown in the figure), and its main structure is the same as that of the prior art, including the axle box, in which the main power shaft is arranged, and the two ends of the main power shaft are connected with the axle box. Rotationally connected, the main power shaft is driven to rotate by the driver arranged on the upper part of the axle box. The main power shaft is provided with several direction-changing gear sets, and several direction-changing gear sets drive several power shafts to rotate respectively. One end of several power shafts protrudes from the outside of the axle box. The power shafts have many different orientations, including the power shaft facing the main shaft clamping device, the power shaft facing the sub shaft clamping device, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com