Complex load behavior simulation and performance test apparatus for servo system

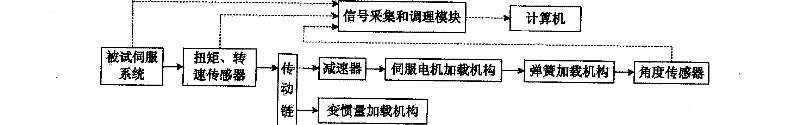

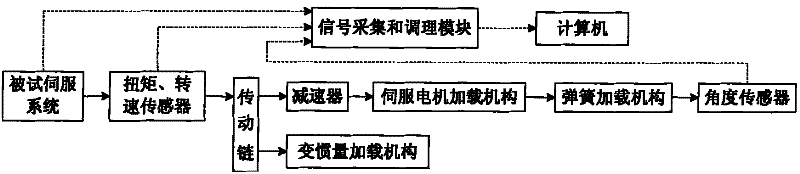

A technology of servo system and load condition, applied in the direction of motor generator testing, etc., can solve the problem of single loading method of loading mechanism, and achieve the effect of controllable load size and wide loading frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

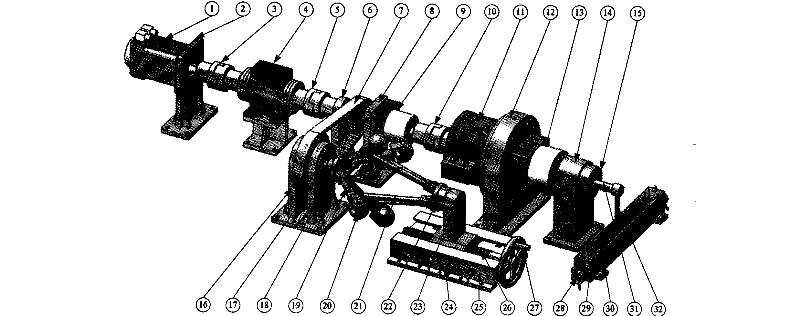

[0035] The tested motor 1 is installed on the tested motor bracket, the output is connected to the torque speed sensor 4 through the coupling A3, the output of the torque speed sensor 4 is connected to the synchronous pulley 7 through the transmission chain input shaft 6 through the coupling B5, and the synchronous pulley 7 The output is connected to the variable inertia loading mechanism. At the same time, the input shaft 6 of the synchronous pulley is output to the speed reducer 9, the output of the speed reducer 9 is connected to the drive shaft of the servo motor through the coupling C10, and the output of the drive shaft of the servo motor is connected to the spring loading mechanism.

[0036] In order to realize the simultaneous loading of the servo motor and the spring loading mechanism, the servo motor 11 adopts a hollow shaft type, the drive shaft of the servo motor and the stator of the servo motor 11 are an interference fit, and the drive shaft of the servo motor is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com