Colourful noctilucent rubber fender

A rubber fender and fender technology, applied in luminous materials, ship construction, ships, etc., can solve problems such as poor visibility, difficult maintenance, high berthing speed, etc., and achieve high-quality performance, beautiful appearance, and good visual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

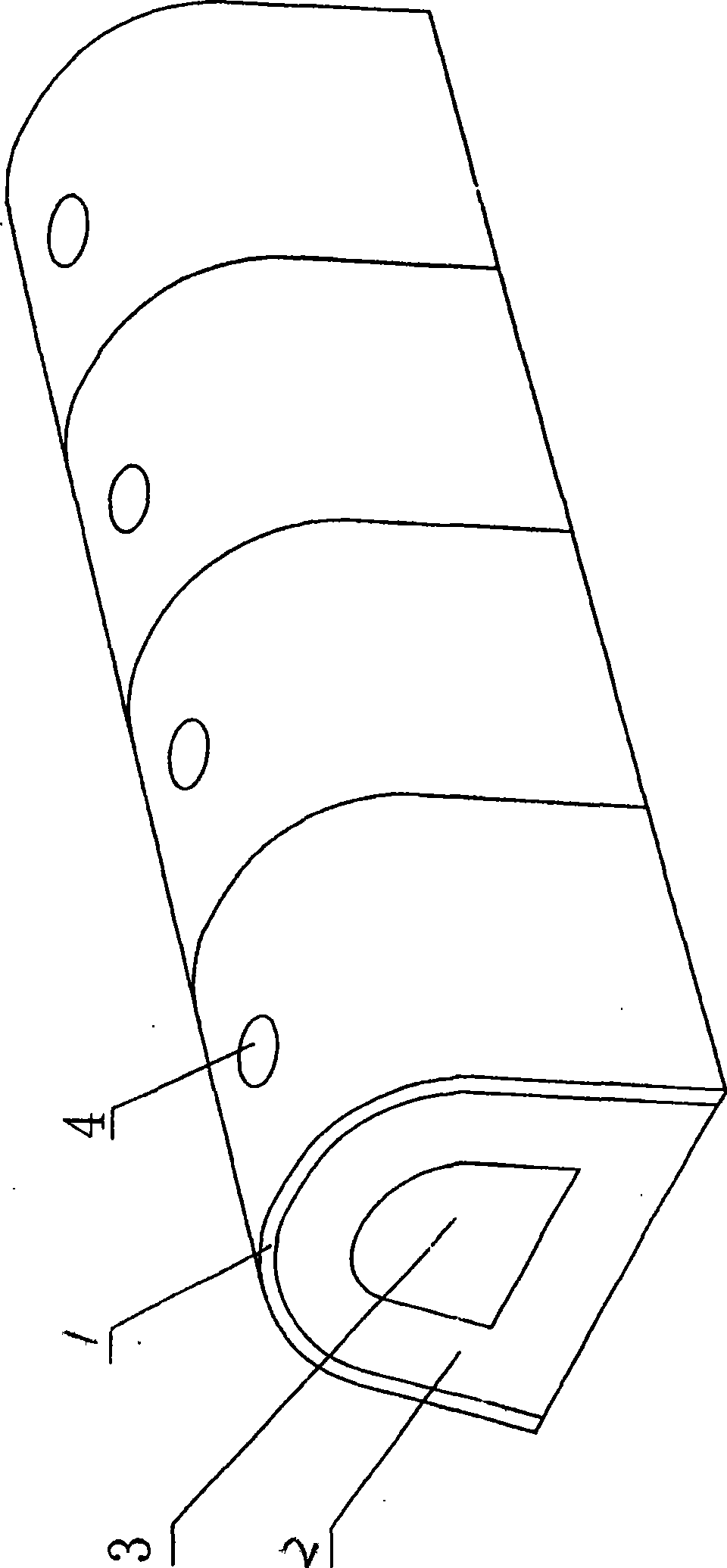

[0017] The color luminous rubber fender is a semicircular cavity fender 1, which is made of natural rubber 15kg, styrene-butadiene rubber 15kg, butadiene rubber 18kg, polyurethane rubber 13kg, afterglow luminous powder (fluorescent agent) 2kg, reflective powder 6kg, zinc oxide 2.3kg, stearic acid 1.0kg, coumaron 0.4kg, light calcium carbonate 20kg, carbon black 28kg, pine tar oil 3kg, sulfur powder 1kg, accelerator DM 0.8kg, antioxidant RD 0.6kg and toner 3kg is mixed evenly, and it is prepared by vulcanization after being molded. Wherein mixing is a known technique.

Embodiment 2

[0019] The color luminous rubber fender is an arch type (DA type) cavity fender 1, which is made of natural rubber 20kg, styrene-butadiene rubber 19kg, butadiene rubber 20kg, polyurethane rubber 25kg, afterglow luminous powder 3kg, reflective powder 9kg , Zinc Oxide 3kg, Stearic Acid 1.3kg, Coumaron 0.8kg, Light Calcium Carbonate 23kg, Carbon Black 30kg, Pine Tar 4kg, Sulfur Powder 1.3kg, Accelerator DM 1kg, Antiaging Agent RD 0.8kg and Toner 4kg Refined evenly, prepared by vulcanization after mold molding.

Embodiment 3

[0021] The color luminous rubber fender is a drum-shaped cavity fender, which is made of natural rubber 25kg, styrene-butadiene rubber 25kg, butadiene rubber 22kg, polyurethane rubber 18kg, afterglow luminescent powder 3.5kg, reflective powder 10kg, zinc oxide 4kg, 1.5kg of stearic acid, 1.0kg of Coumaron, 25kg of light calcium carbonate, 35kg of carbon black, 5kg of pine tar, 1.5kg of sulfur powder, 1.2kg of accelerator DM, 1.0kg of antioxidant RD and 5kg of toner were mixed evenly. After the mold is formed, it is prepared by vulcanization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com