Automobile door glass composite guiding rail and method for producing the same

A technology for door glass and guide rails, which is applied to vehicle parts, engine sealing, sealing devices, etc., can solve the problems of the sealing strip being easy to fall off the rail body, and the door glass being easily inserted between the rail body and the sealing strip.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

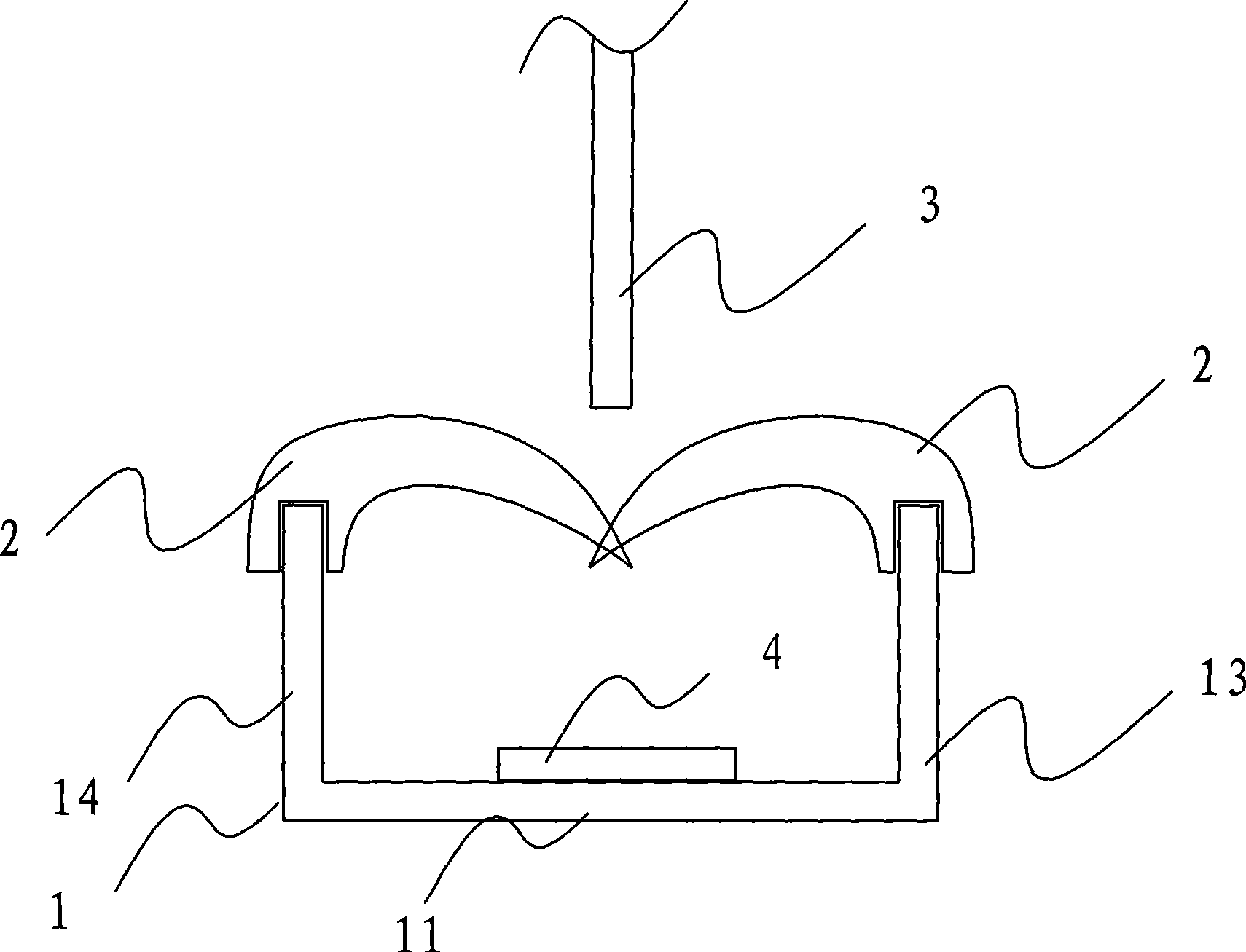

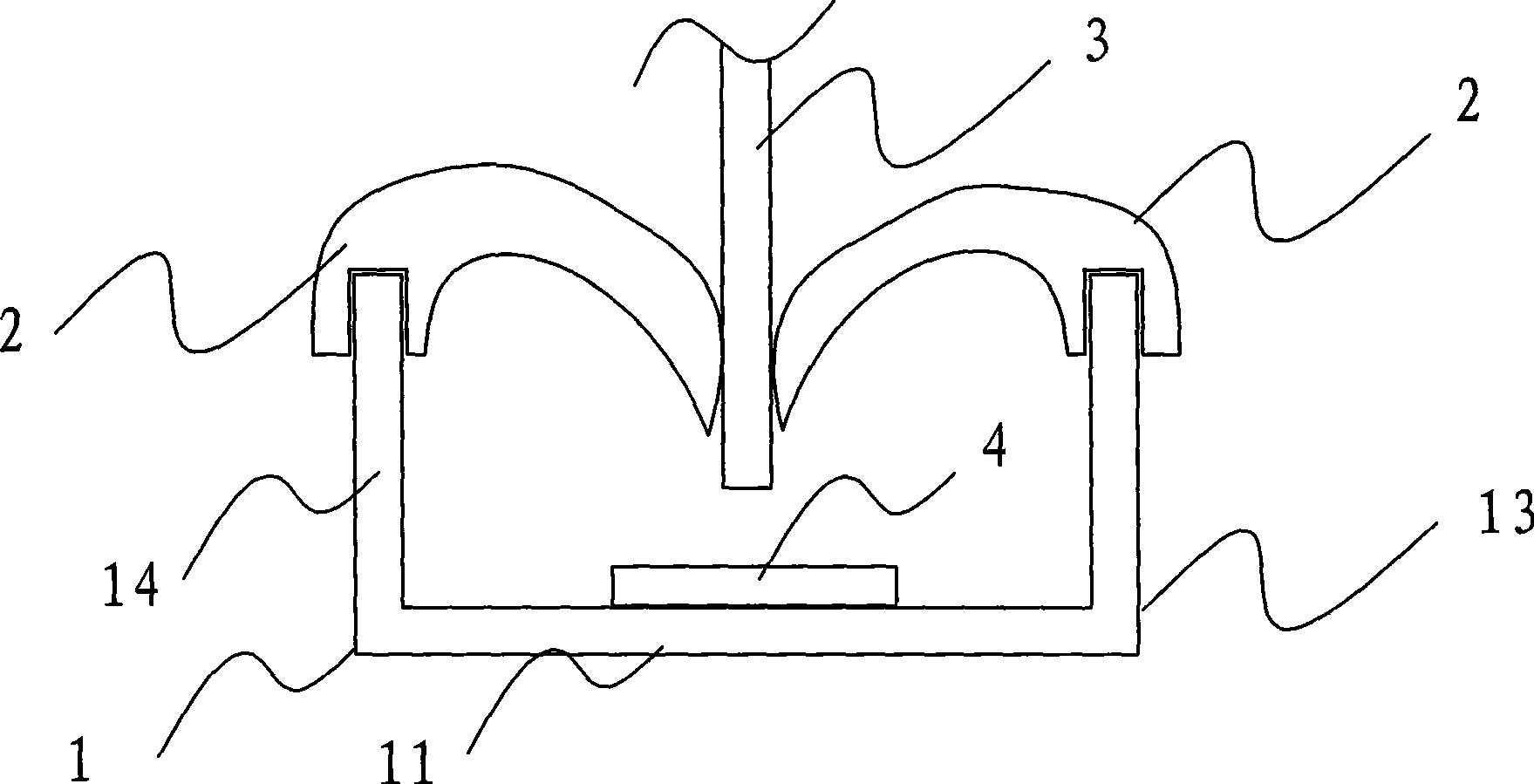

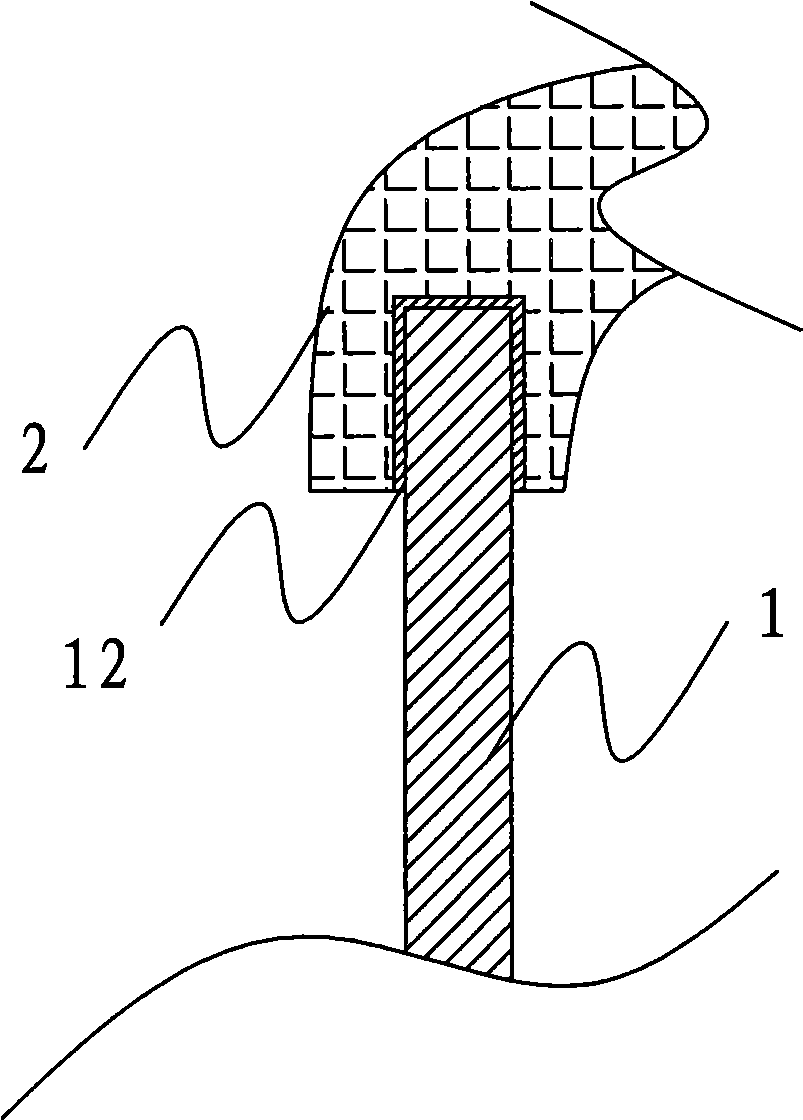

[0026] Such as figure 1 As shown, in an embodiment of the door glass composite guide rail and its manufacturing method of the present invention, the car door glass composite guide rail has a certain length, and the structural schematic diagram of its cross section is shown in figure 1 Among them, the door glass 3 has not been put into the composite door glass guide rail. In addition, the composite door glass guide rail includes a guide rail main body 1 and a sealing strip 2, and the guide rail main body 1 includes a figure 1 The base 11 at the bottom, the inner side wall 13 and the outer side wall 14 connected to the base 11, the base 11, the inner side wall 13 and the outer side wall 14 are connected to roughly form a U shape; the sealing strip 2 is respectively connected to the inner side wall 13 and the outer wall 14 of the vehicle, and respectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com