Method for stitching and repairing mechanical damage of radial tire

A radial tire and tire technology, applied in tires, other household appliances, household appliances, etc., can solve the problems of tire bulging and repaired place being damaged again, and achieve the effect of improving safety, reducing economic waste and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

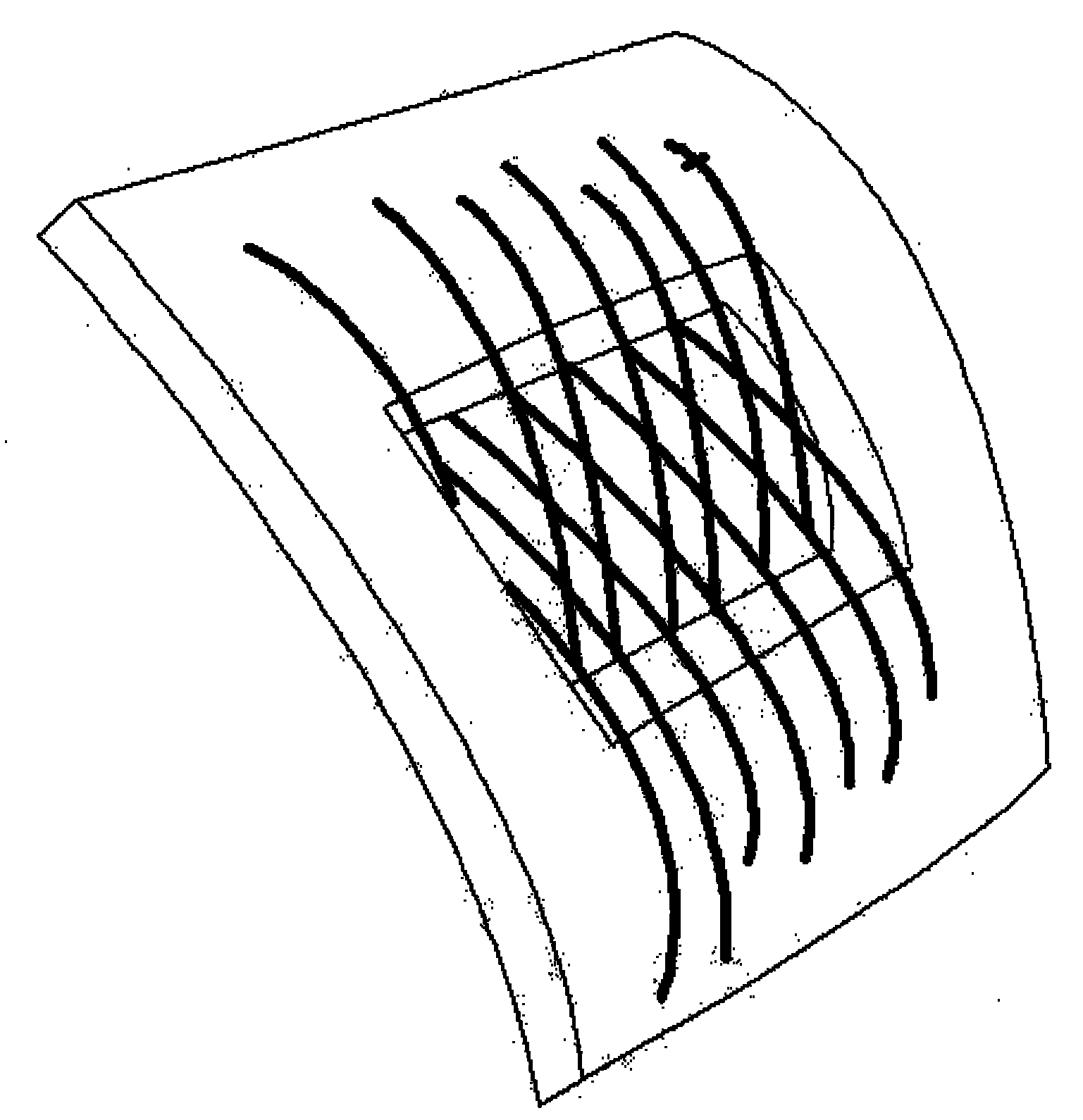

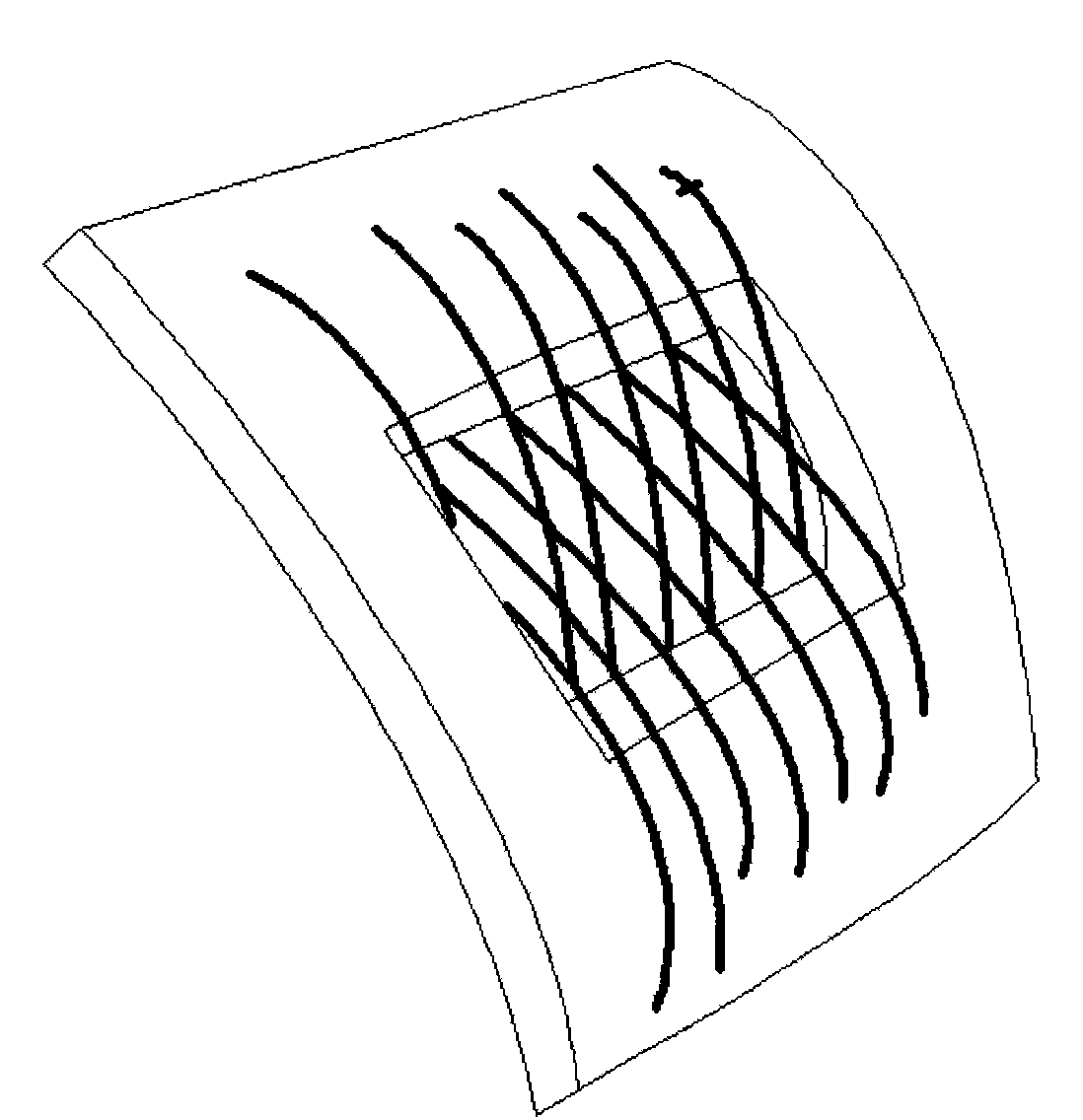

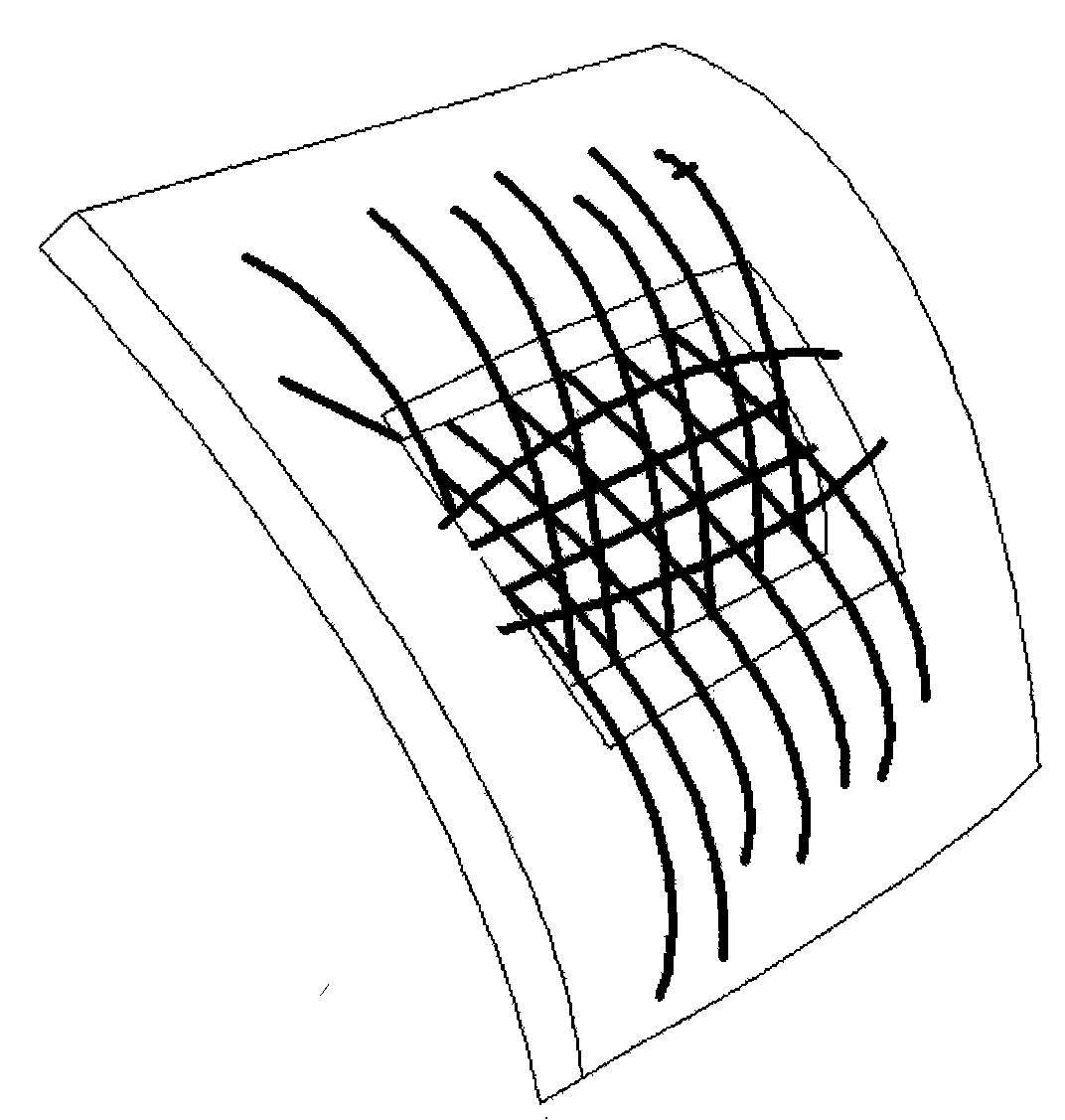

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0036] With reference to Fig. 1, the method for stitching and repairing radial tire flaws comprises the following steps:

[0037] 1. Observe whether the injured part of the tire is within the repairable range:

[0038] The upper part of the wound should not exceed the tire shoulder, the lower part should not be close to the tire opening, the overall width of the wound should not exceed 55mm, and the maximum length and maximum width cannot exist at the same time, that is, it can be repaired. There are generally three types of wounds that can be repaired:

[0039] 1. Only one wound.

[0040] 2. Two wounds separated upper and lower.

[0041] 3. The side wall is injured and the internal injury is not leaking but bulging.

[0042] Second, the plastic treatment of the wound:

[0043] 1. Use a curved rubber digging knife to dig in a square or a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com