Method and apparatus for detecting contact head abrasive loss of vacuum circuit breaker

A vacuum circuit breaker and wear amount technology, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of unintuitive detection results, inconvenient operation, and untimely detection, and achieve intuitive display, high measurement accuracy, Simple and fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below with reference to the accompanying drawings.

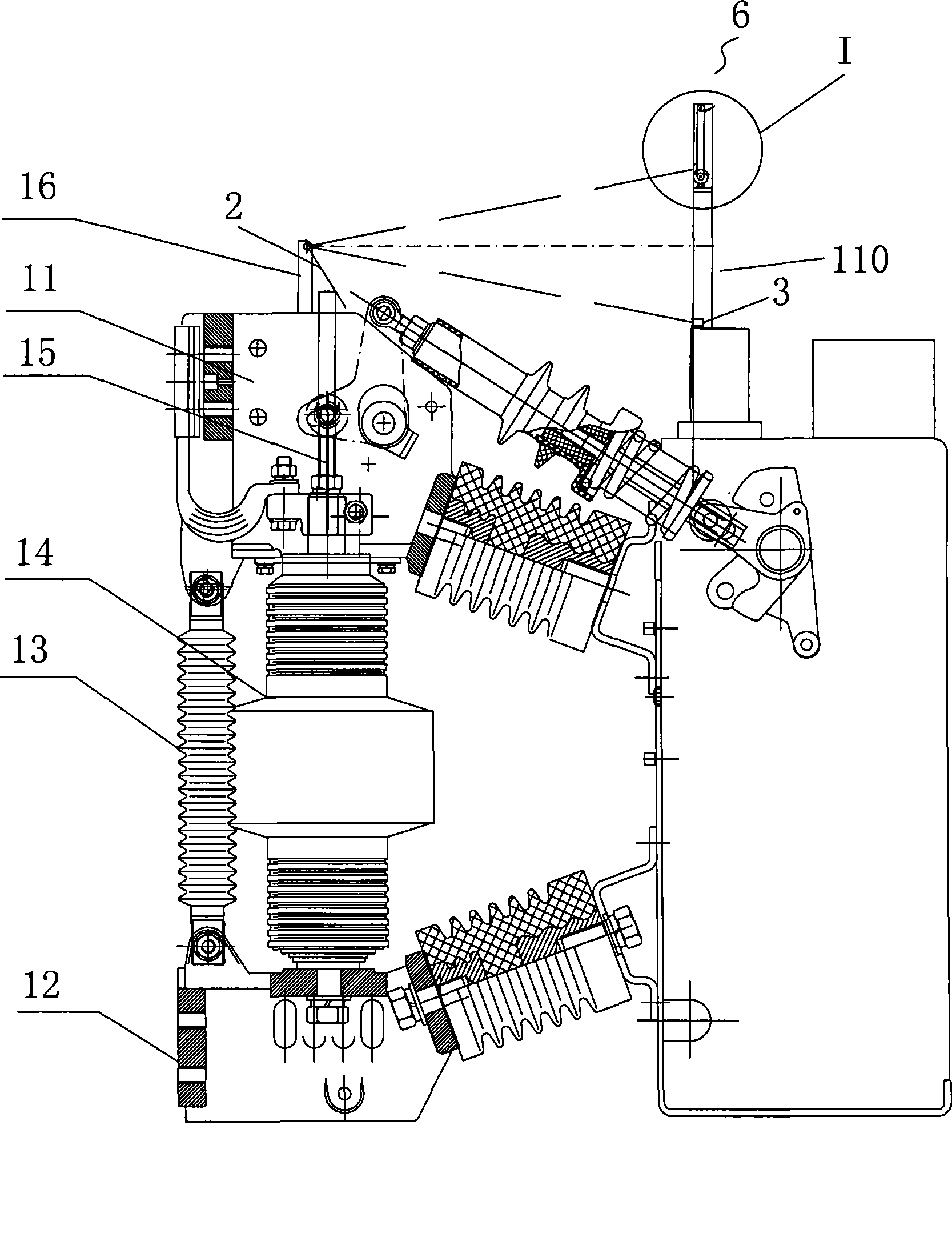

[0015] figure 1 The main structure of the vacuum circuit breaker is shown, including the moving support 11, the static support 12, the insulating rod 13, the vacuum interrupter 14, the moving conductive rod 15, the moving contact and the static contact, etc., wherein the moving contact and the static contact The head is located in the vacuum interrupter 14, and one end of the movable conductive rod 15 is connected to the movable contact in the vacuum interrupter through the cover plate of the vacuum interrupter. In order to facilitate the clear representation of the present invention, figure 1 The vacuum circuit breaker in the structure is inverted with the actual vacuum circuit breaker.

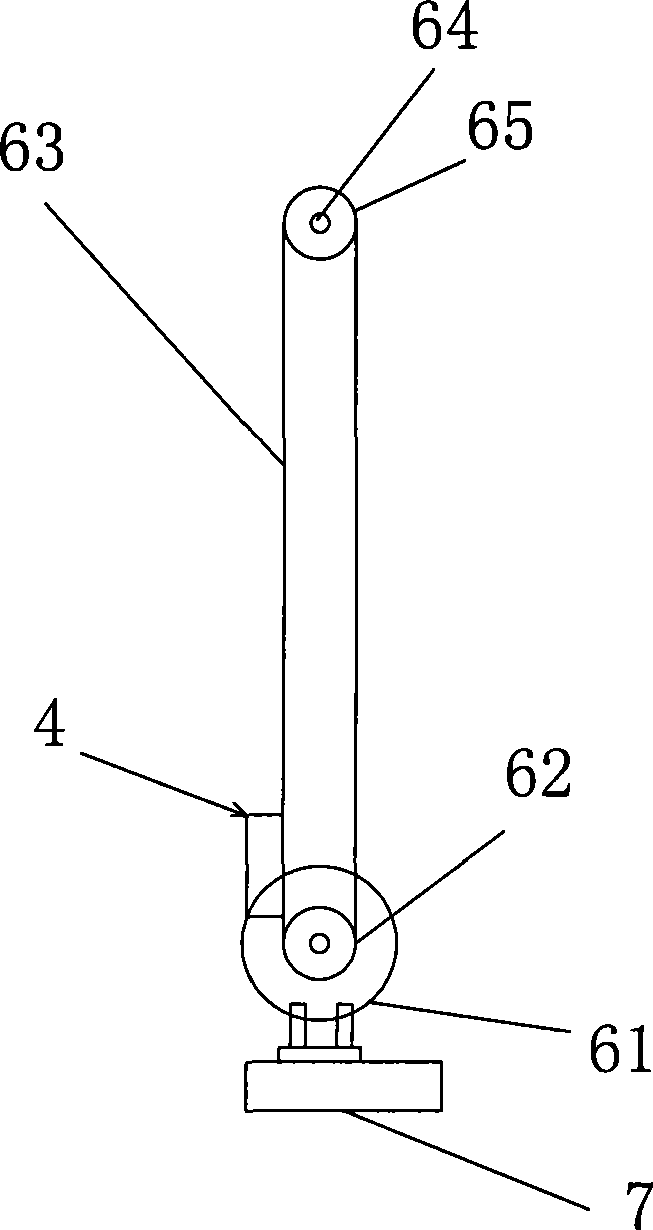

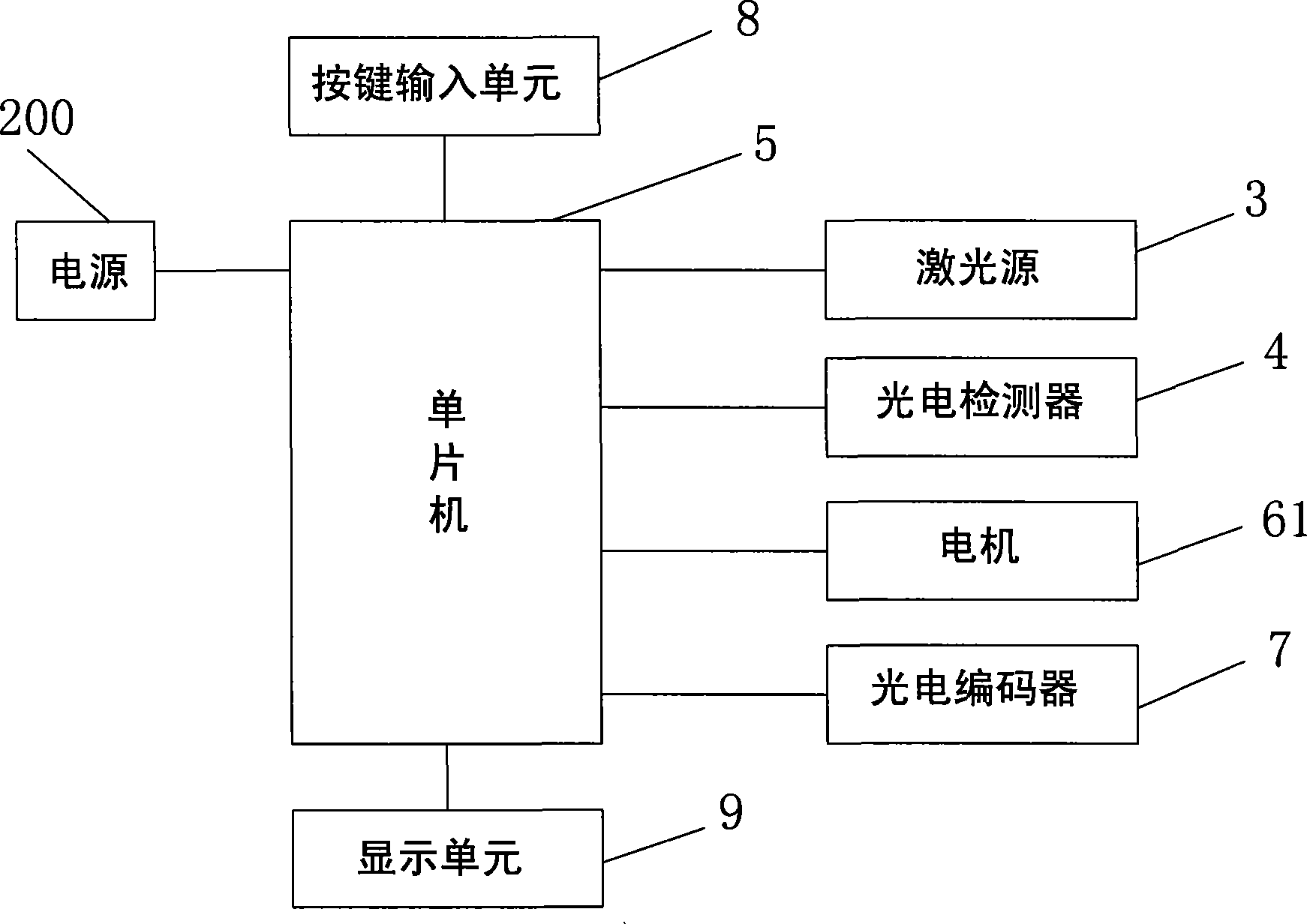

[0016] The method of the present invention for detecting the contact wear of a vacuum circuit breaker is that a reflection device is arranged on the other end of the movable conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com