Automatic control device and method for sewing machine cloth-dragging wheel

A technology of automatic control device and mop wheel, which is applied in the direction of sewing machine control device, sewing machine components, sewing equipment, etc., can solve the problems of low work efficiency and high work intensity of the operator, so as to improve work efficiency, reduce labor intensity, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment, the present invention is described further clearly and completely:

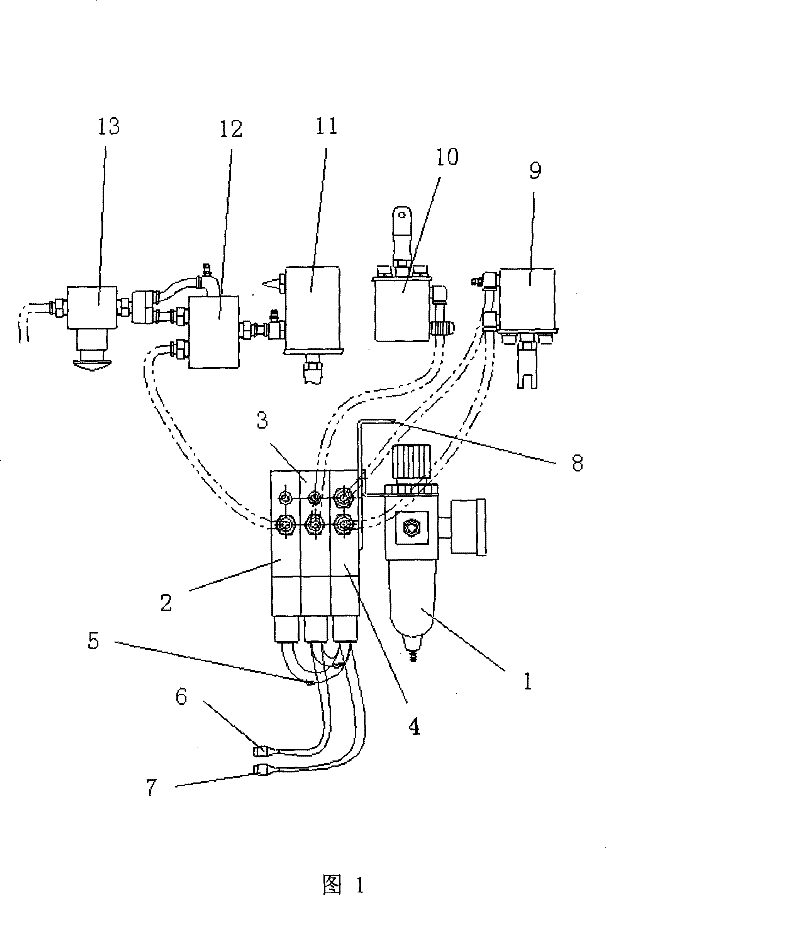

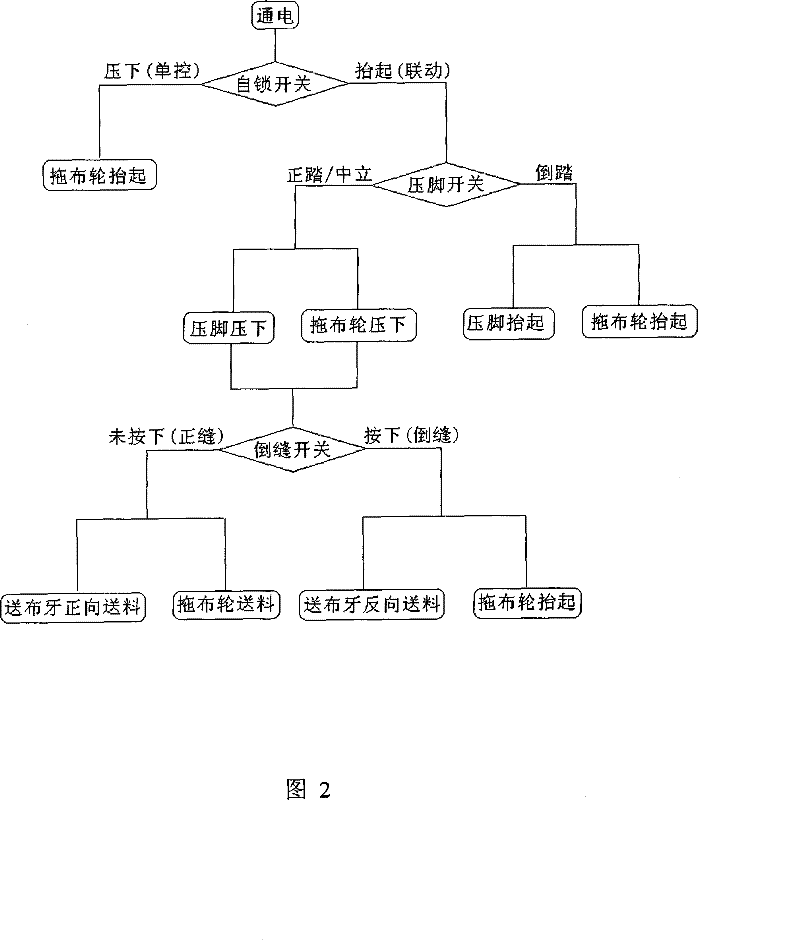

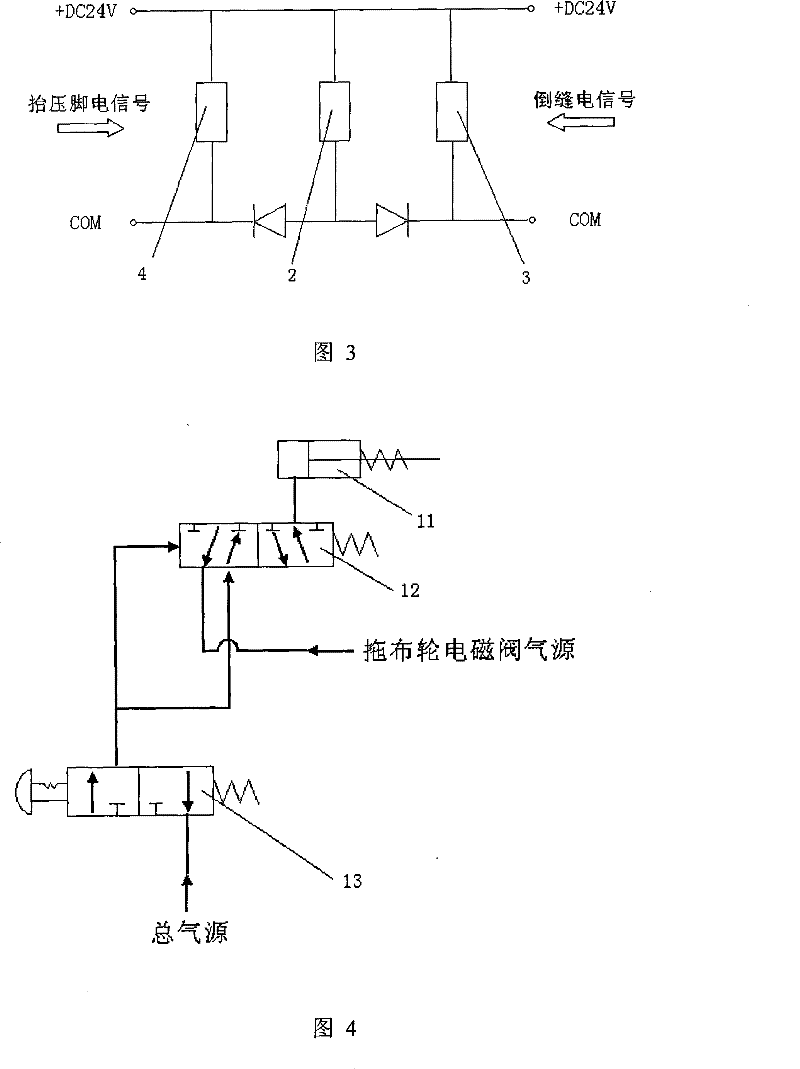

[0018] See figure 1 , 3 And 4, an automatic control device of a sewing machine mop wheel, comprising a filter pressure regulator 1 connected to an air source, and its air outlet is respectively connected to the air inlet of the mop wheel solenoid valve 2, the reverse sewing solenoid valve 3 and the presser foot solenoid valve 4 connected, the air outlets of the mop wheel solenoid valve 2, the reverse stitch solenoid valve 3 and the presser foot solenoid valve 4 are respectively connected with the mop wheel cylinder 11, the reverse stitch cylinder 10 and the presser foot cylinder 9, and the reverse stitch solenoid valve 3 and The presser foot solenoid valve 4 is connected to the corresponding signal output port of the control box through wires 6 and 7 respectively, and a three-port two-position pneumatic valve 12 is connected betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com