Countercurrent flow esterification reactor for preparing biodiesel and method thereof

A technology of esterification reaction and biodiesel, which is applied in the direction of fatty acid esterification, petroleum industry, biological raw materials, etc., can solve the problems of many by-products, large alcohol consumption, uneconomical and environmental problems, and achieve simple process and high efficiency. conversion rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to further illustrate the technical means and effects that the present invention takes to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the reverse flow esterification reactor and method thereof for producing biodiesel proposed according to the present invention will be described. Specific embodiments, structures, features and effects thereof are described in detail below.

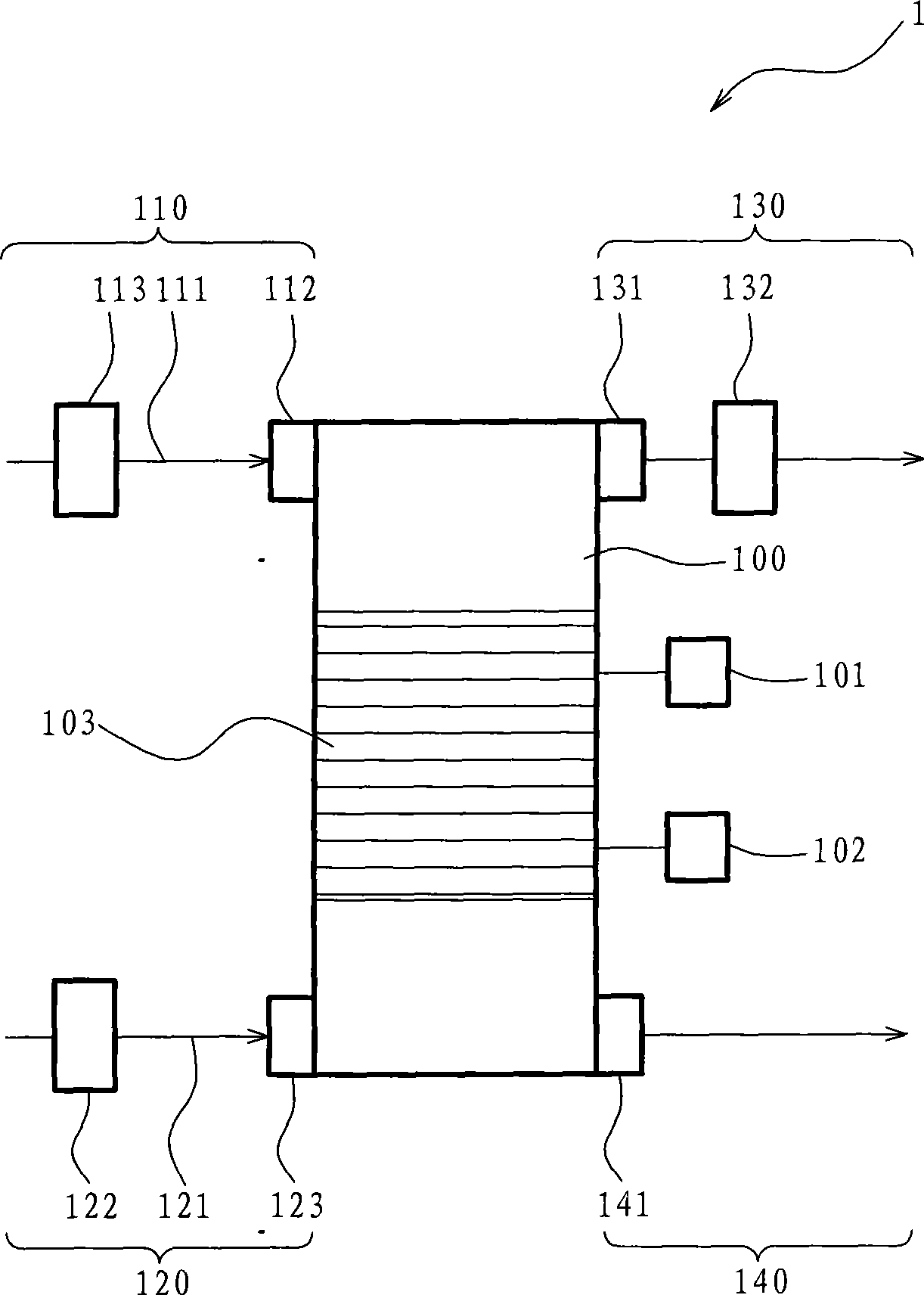

[0049] Please refer to figure 1 As shown, it is the reverse flow esterification reactor 1 for producing biodiesel (Bio-diesel, Fatty AcidMethyl Ester, FAME) in the present invention, and the esterification reaction tower (Packed Reactor, Esterification Tower) 100 is a barrel-shaped metal hollow tank body, which can bear the air pressure below 40 million pascals (Mpa), there is a sieve tray (SieveTray) 103 in the esterification reaction tower (Esterification Reactor) 100, which is used to make the raw materials e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com