Ink injection means capable of accurately setting ink injection amount and injecting ink from inlet channel without damaging ink cartridge

A technology of air inlet and ink filling machine, applied in printing, special dispensing devices, packaging, etc., can solve the problems of easy clogging of nozzles, reduction of repeated service life of ink cartridges, and difficulty in implementation, so as to avoid quantitative errors and ink filling process Clean and convenient, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

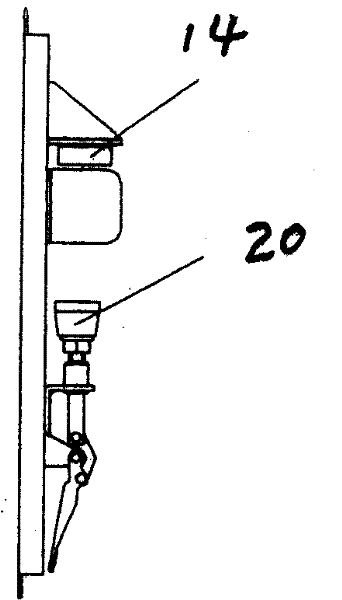

[0048] Such as Figure 7 , 8 As shown, the peristaltic pump 1 designed by the present invention is assembled by the pump head and the motor 2. After one side of the bracket 3 is assembled with the motor by screws, the other side is assembled with one side of the pump cover, and the other side of the pump cover is equipped with a three-claw bracket. , the three claws of the three-claw bracket are respectively installed with three rollers 4, and the end faces of the rollers are inlaid with iron sheets 5, and the silicone tube 8 is put on two clips and then put into the pump bowl, and the clips are inserted into the U-shaped groove at the bottom of the pump bowl, To fix the silicone tube, buckle the pump bowl with the fixed silicone tube together with the pump cover with the rollers assembled above. At this time, the three rollers tightly squeeze the silicone tube. After assembling the peristaltic pump, the motor shaft passes through the bracket, The pump cover and the motor sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com