Method for casting cylinder cover of multicylinder one-cover engine

A technology for engine cylinders and casting molds, which is applied in the direction of casting molding equipment, casting molds, and casting mold components. It can solve the problems of increasing rotation defects, reducing positioning reliability, and increasing sand core deformability. The effect of reducing deviation and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

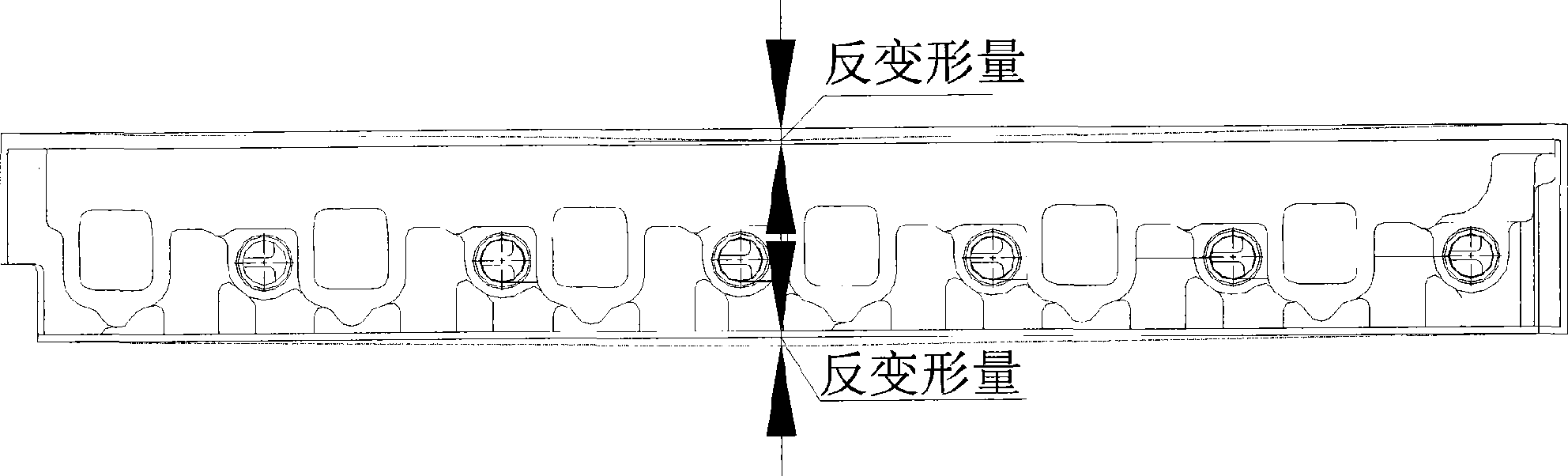

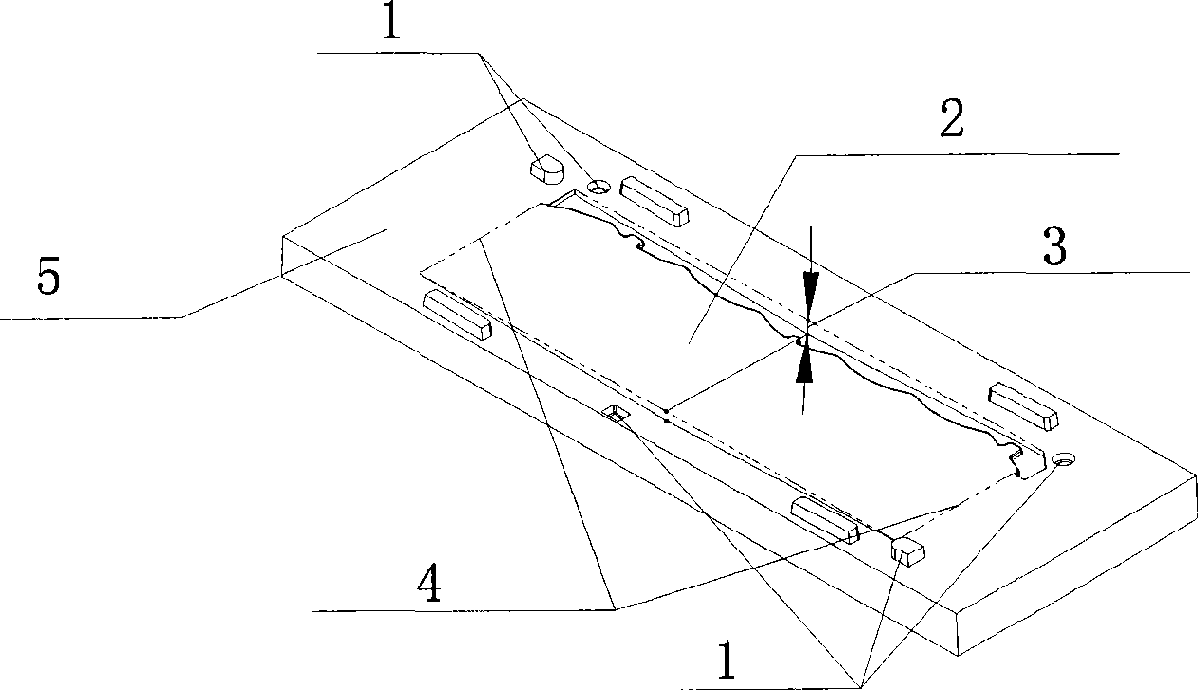

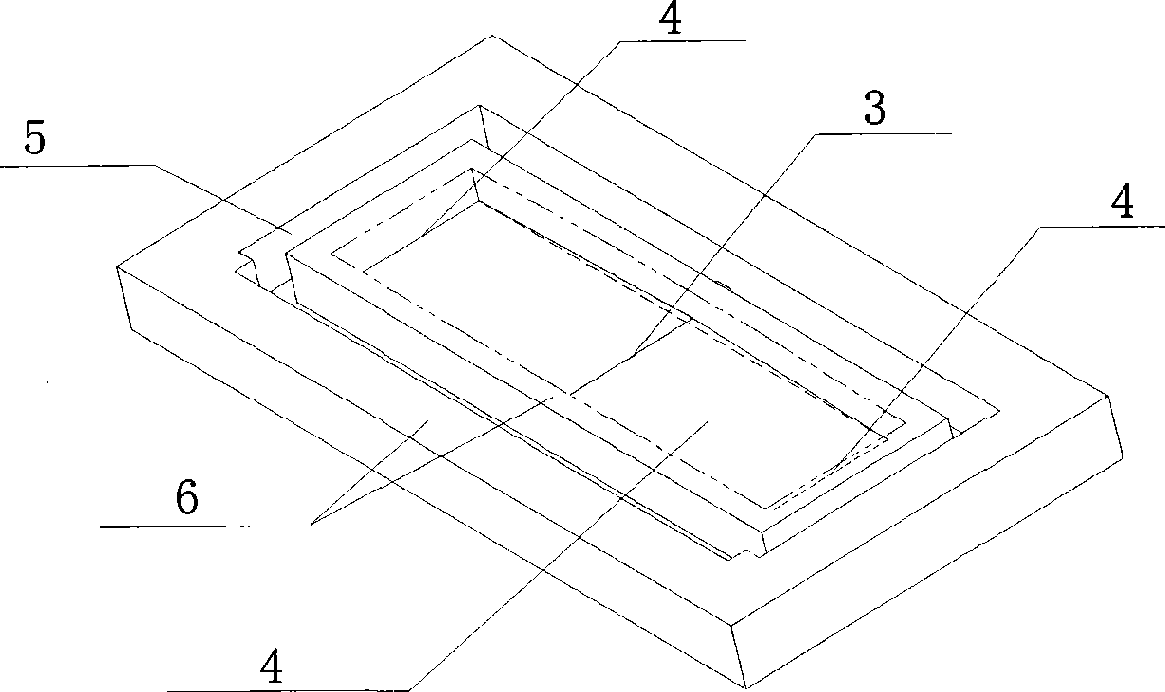

[0023] In the anti-deformation mold design of the multi-cylinder one-lid engine cylinder head of the present invention, the shape of each sand core is based on the wide-mouth "V" shape of the deformation of the casting, and the relative position of the wide-mouth "V" shape where the sand core is located is determined to make a corresponding The shape of the wide-mouthed "V"-shaped sand core in the direction, the upper and lower wide-mouthed "V" shapes of each set of core boxes are determined according to the wide-mouthed "V" shape of the sand core that is adjacent to it. The bottom surface is convex and the top surface is concave. The starting point of the wide-mouth "V" shape anti-deformation design is the center point of the longitudinal length of the mold as the highest point, and the slope surface formed at a certain angle to the edge of the longitudinal length of the mold is the lowest. The end point is designed, and the height of the protrusion at the center point is 1-3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com