Optical glass and lens using the same

An optical glass, quality technology, applied in optics, optical components, instruments, etc., can solve the problems of short durability life of forming molds, high forming temperature, low productivity, etc., achieve excellent molding formability, reduce the percentage of unqualified , the effect of small difference in thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

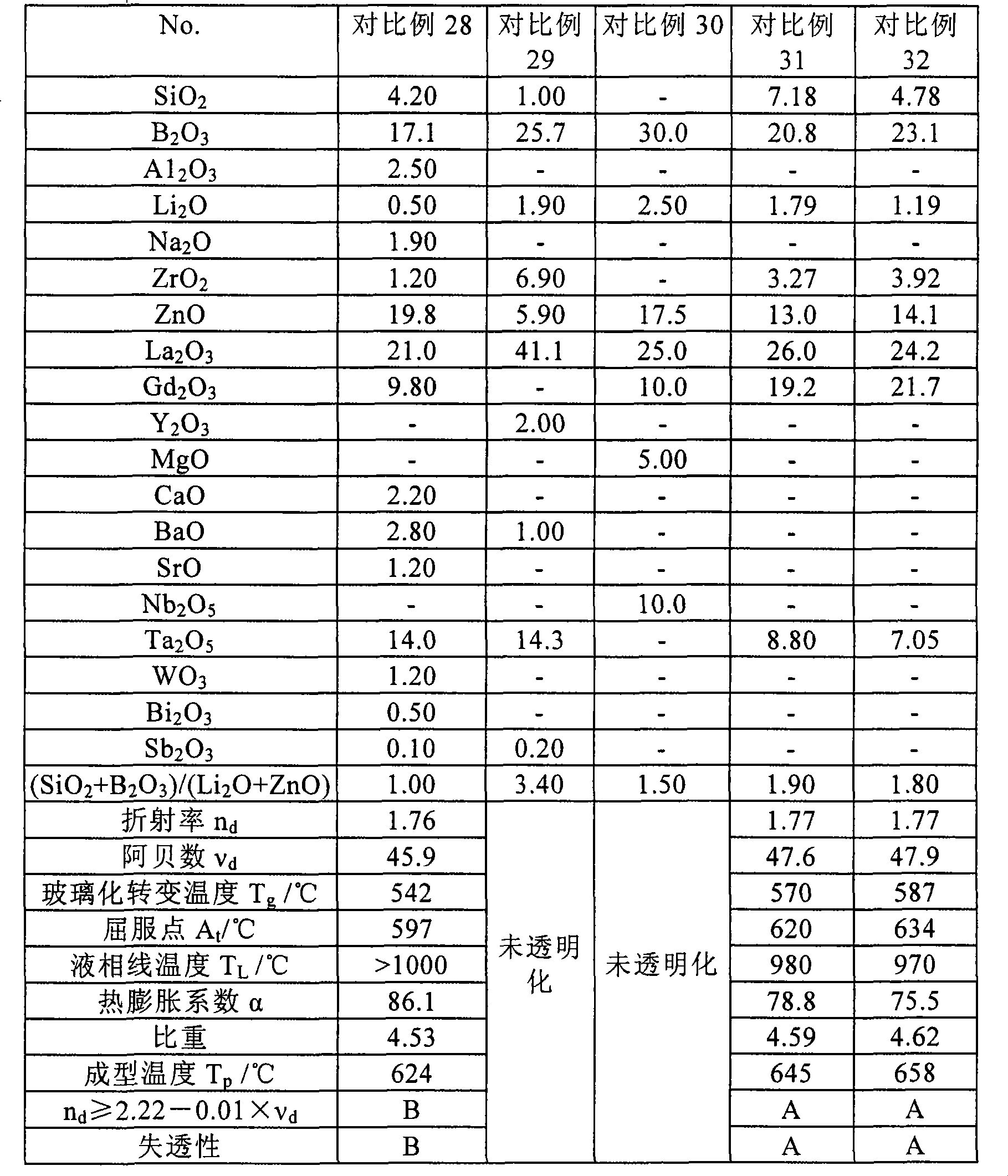

[0064] Embodiments of the present invention will be described below by citing Examples (Examples 1 to 27) and Comparative Examples (Comparative Examples 28 to 32) according to the present invention. However, the present invention should not be construed as being limited thereto.

[0065] As for the raw material preparation method, the raw materials shown below were mixed to obtain glasses having the respective compositions shown in Table 1. The mixture was placed in a crucible made of platinum, and melted at 1,100 to 1,300° C. for 1 hour. In this operation, the contents were stirred with a platinum stirrer for 0.5 hours to homogenize the molten glass. The homogenized molten glass is poured and formed into a plate. Thereafter, place the plate at T g The temperature was maintained at +10°C for 4 hours, and then gradually cooled to room temperature at a cooling rate of -1°C / min. In the table, each part indicated by "-" indicates that the component is not present.

[0066] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com