Etalon and method for producing the same

A technology of etalons and substrates, applied in the fields of optics and etalons, can solve problems such as difficult fabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

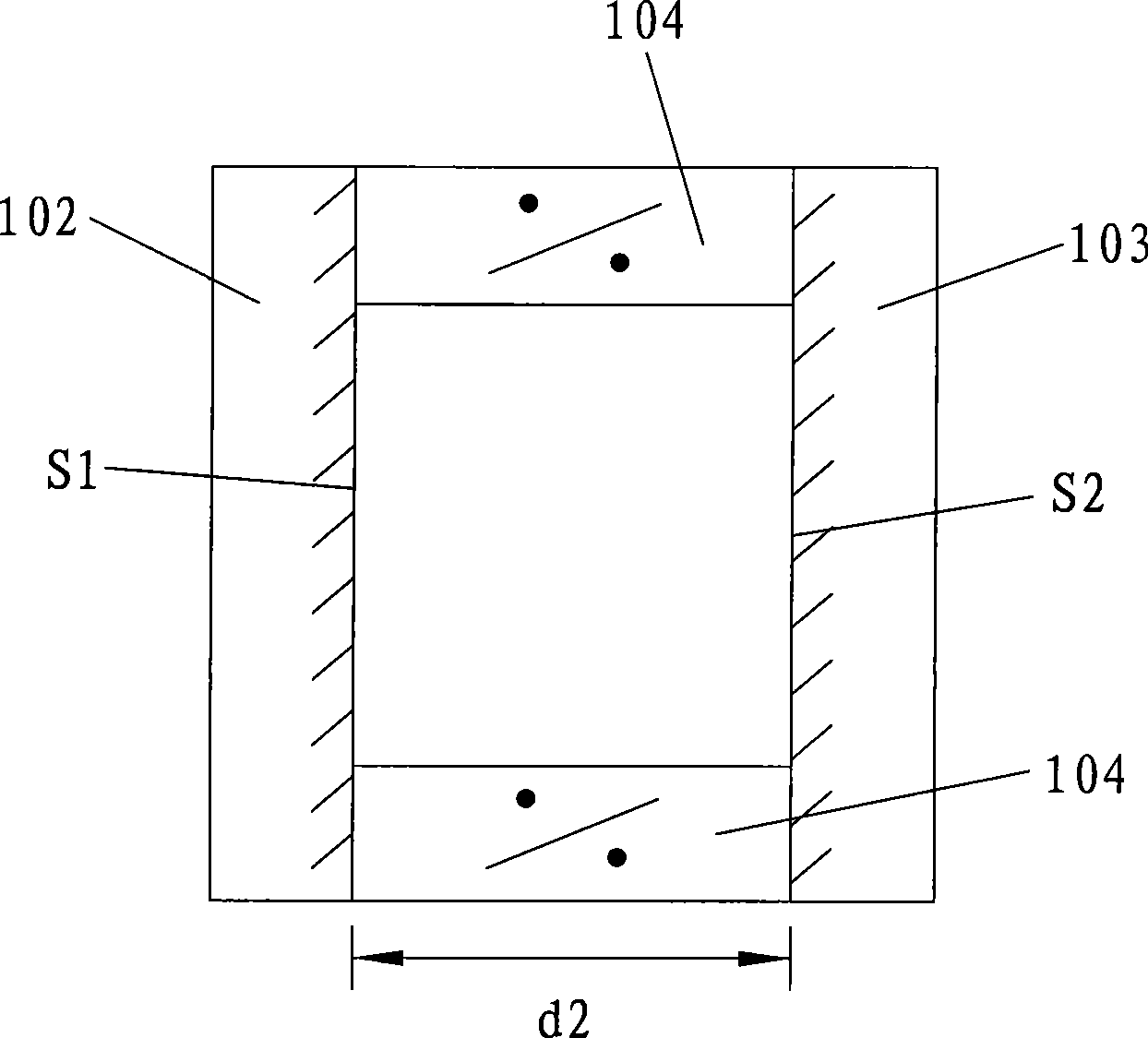

[0041] The etalon of the present invention comprises:

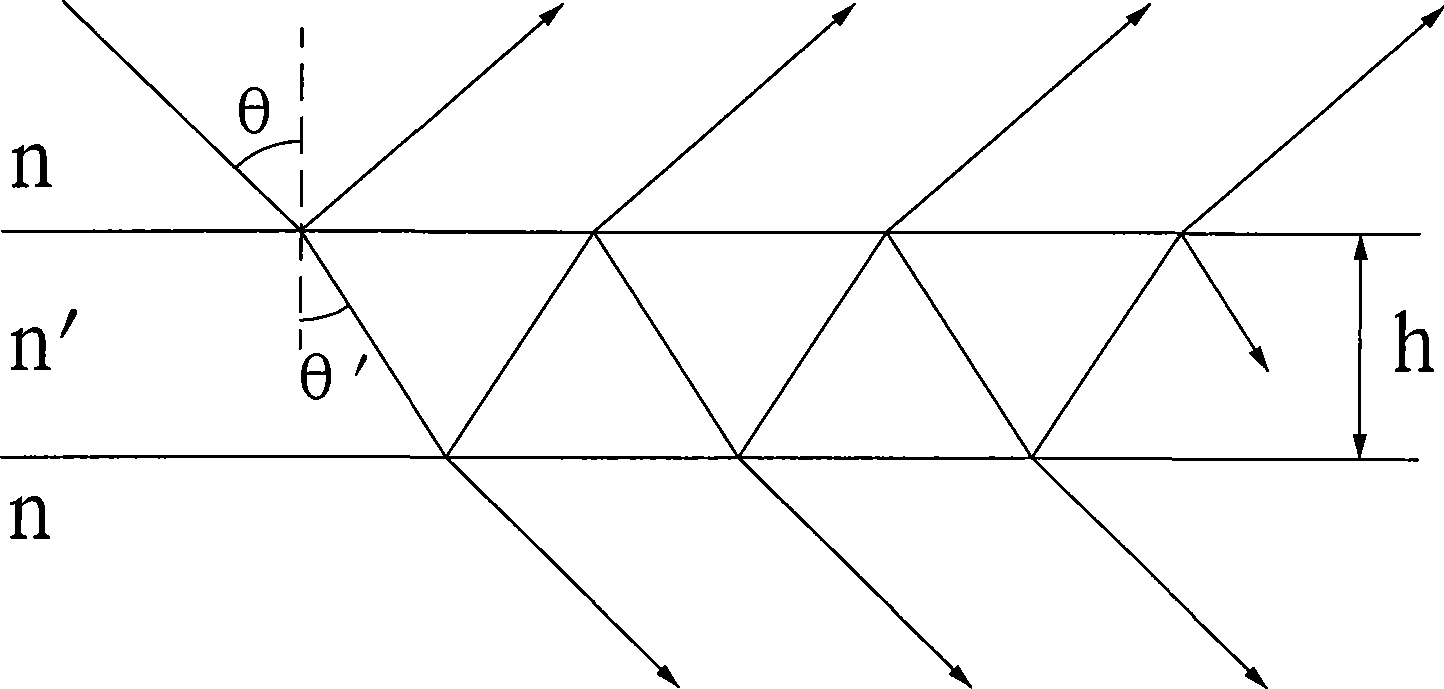

[0042] The first substrate is coated with a specific wavelength reflection or partial reflection film; an optical medium thin layer is coated on the coating surface of the first substrate, and the thickness of the optical medium coating is determined according to the thickness of the designed etalon; The second substrate is coated with a specific wavelength reflection or partial reflection film, and the coating surface is glued to the optical medium thin layer through optical glue or deepening optical glue.

[0043] If the optical medium thin layer is a complete thin layer, a solid etalon is formed.

[0044] If the optical medium thin layer is a thin layer missing in the central region, a cavity etalon is formed.

[0045] The material of the substrate is K9 glass or other optical materials. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com