Kinetic energy generation apparatus with improved output power

A technology for generating devices and outputting power, which is applied in the field of kinetic energy generating devices and can solve problems such as low power output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

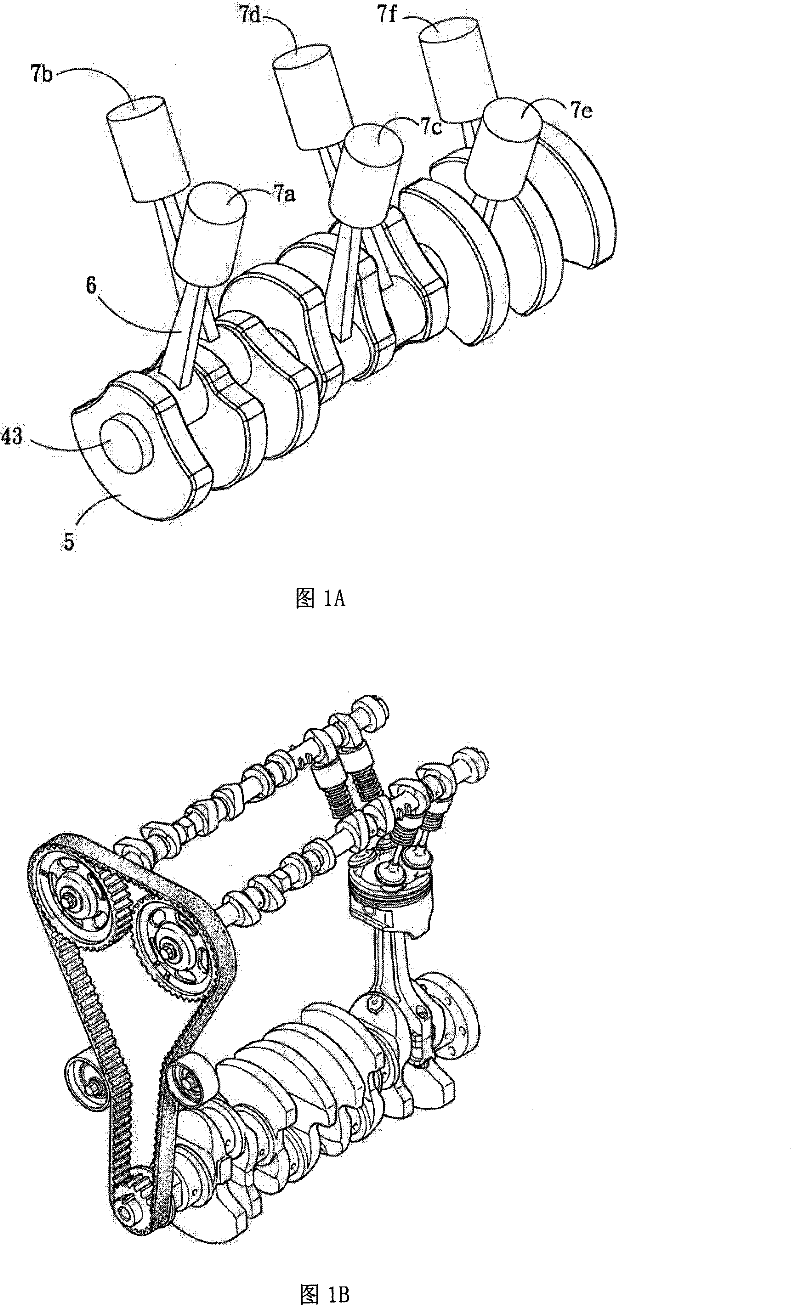

[0052] see Figure 2 to Figure 6 As shown, the present invention provides a kinetic energy generating device for increasing output power, which mainly includes an organic casing 1 , a fixed gear 2 , a movable gear 3 , a transmission member 4 , a flywheel 5 and a connecting rod 6 .

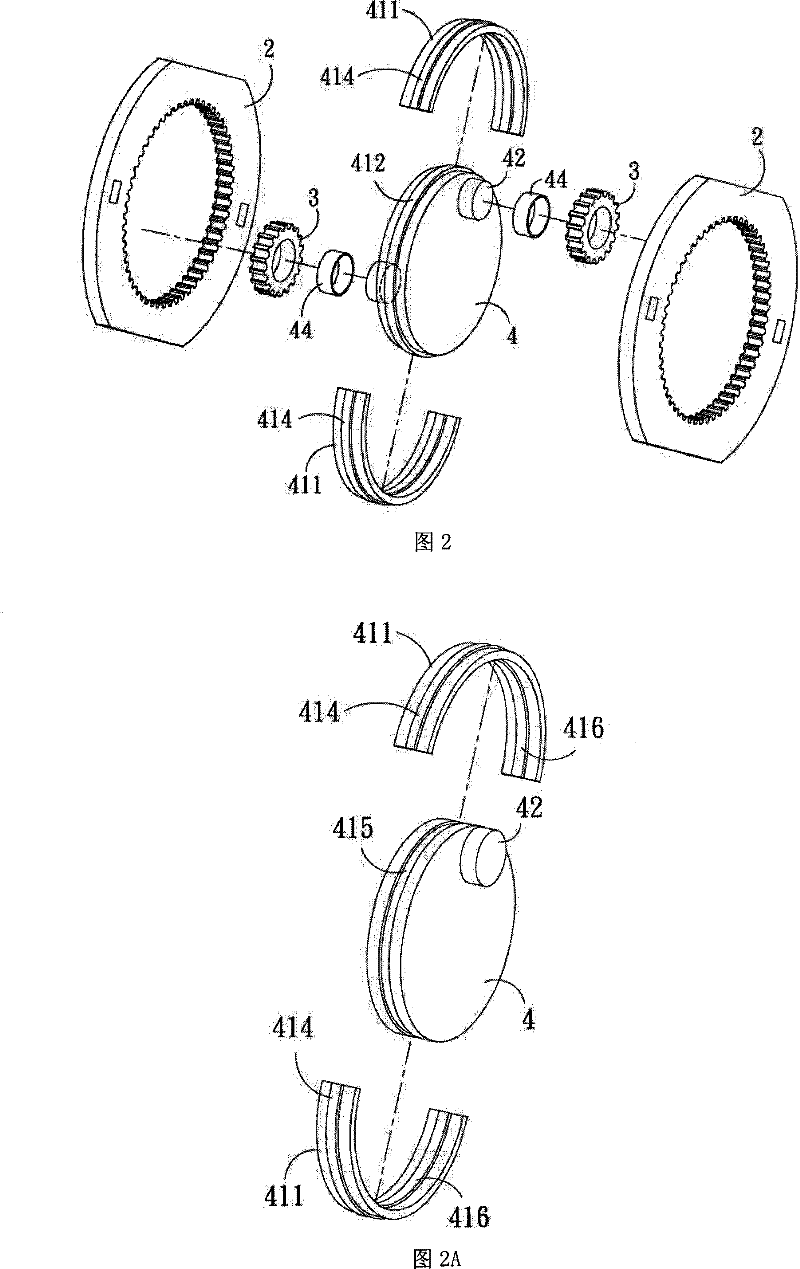

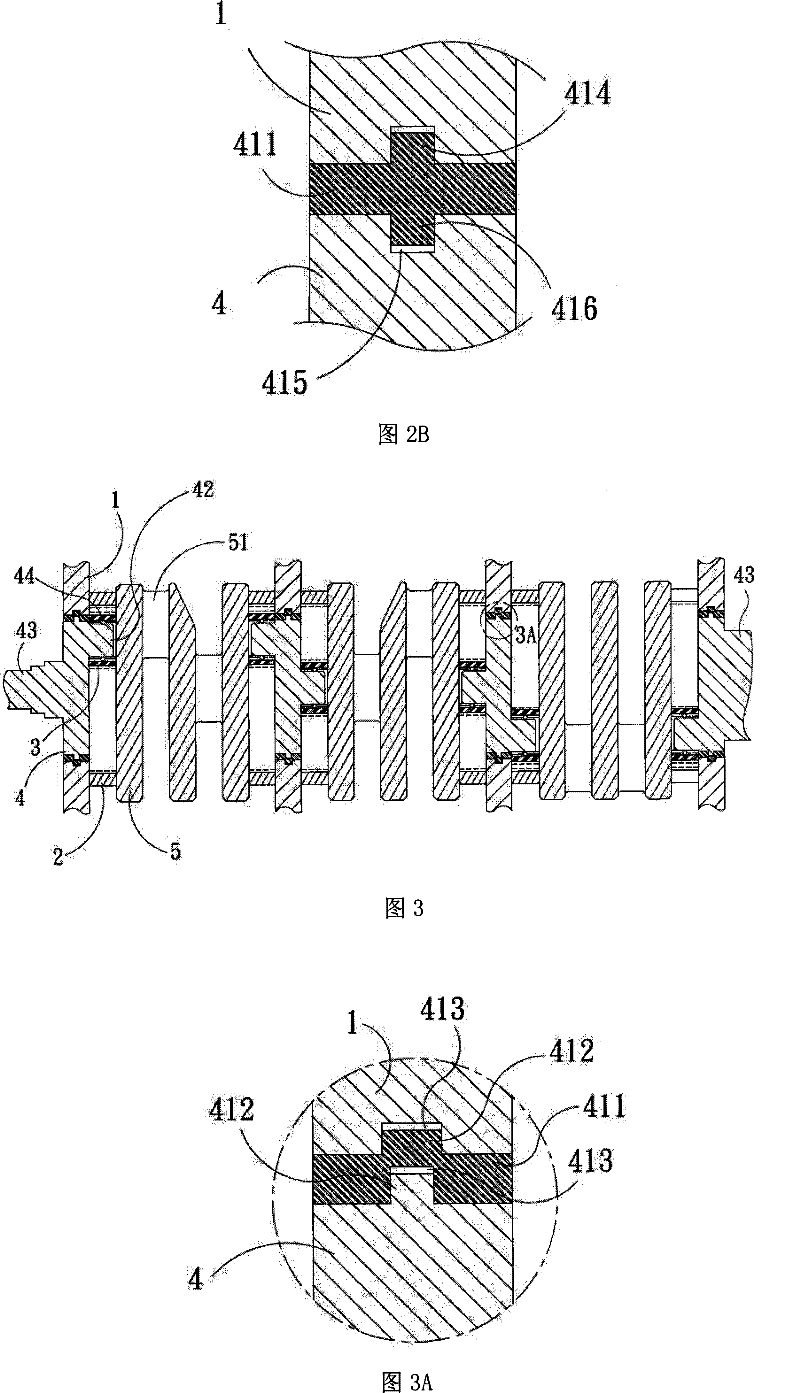

[0053] The fixed gear 2 is arranged on one side of the casing 1 with its tooth shape facing inward, and the movable gear 3 is covered inside the fixed gear 2 with its tooth shape facing outward, so that the fixed gear 2 and the movable gear 3 can be meshed with each other for transmission. , and the gear ratio of the fixed gear 2 and the movable gear 3 is 3:1; and the transmission member 4 is pivotally arranged inside the casing 1 and can rotate to connect the output shaft 43 as a kinetic energy output; the transmission member 4 and the casing 1 The contact surface is provided with Bosi (Bush) 411 (such as figure 2 , Figure 3A ), to improve the stability of the rotation of the transmission part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com