Aluminizing furnace

A technology of aluminizing and electric furnace, which is applied in the field of aluminizing furnace, can solve the problems of aluminizing, failure to reach the iron pot, and color fading of aluminizing, etc., and achieve strong self-control, humanized operation, and uniform temperature on the upper and lower sides of the furnace. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

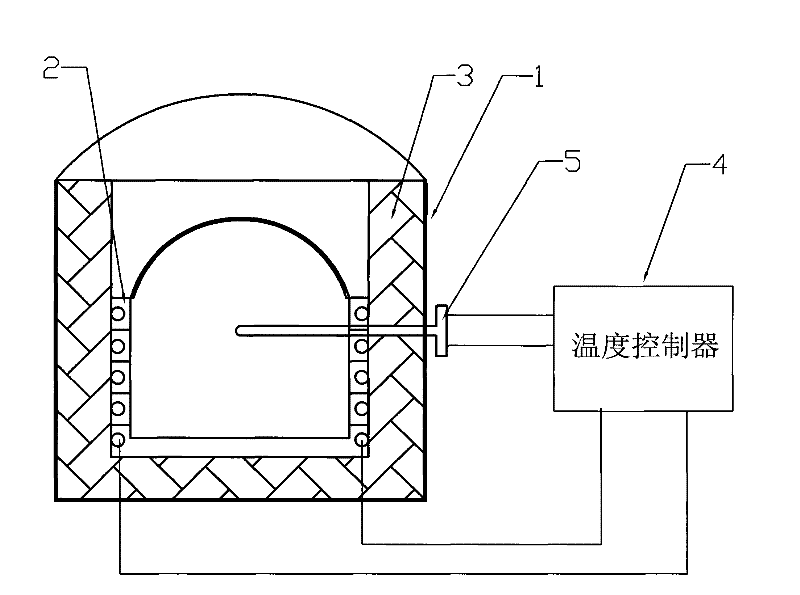

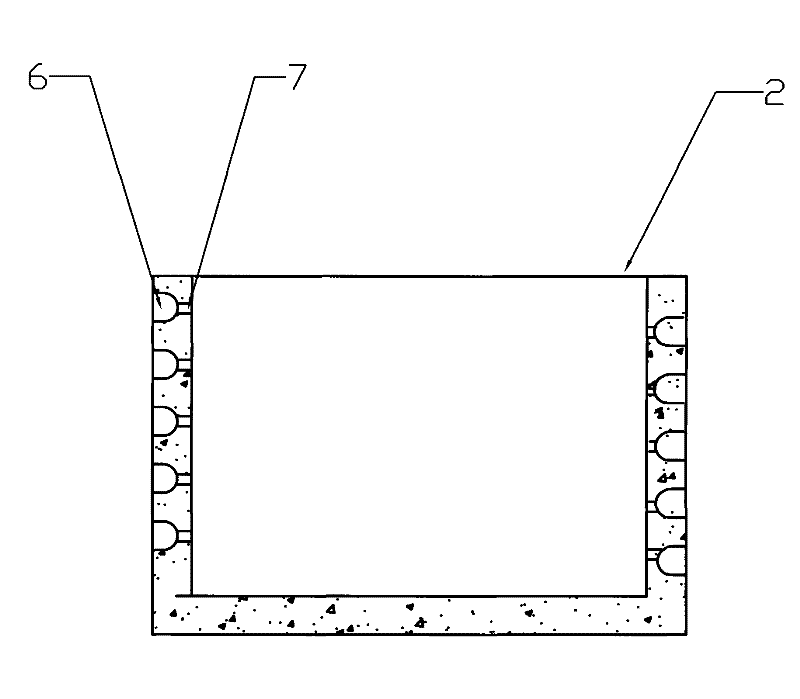

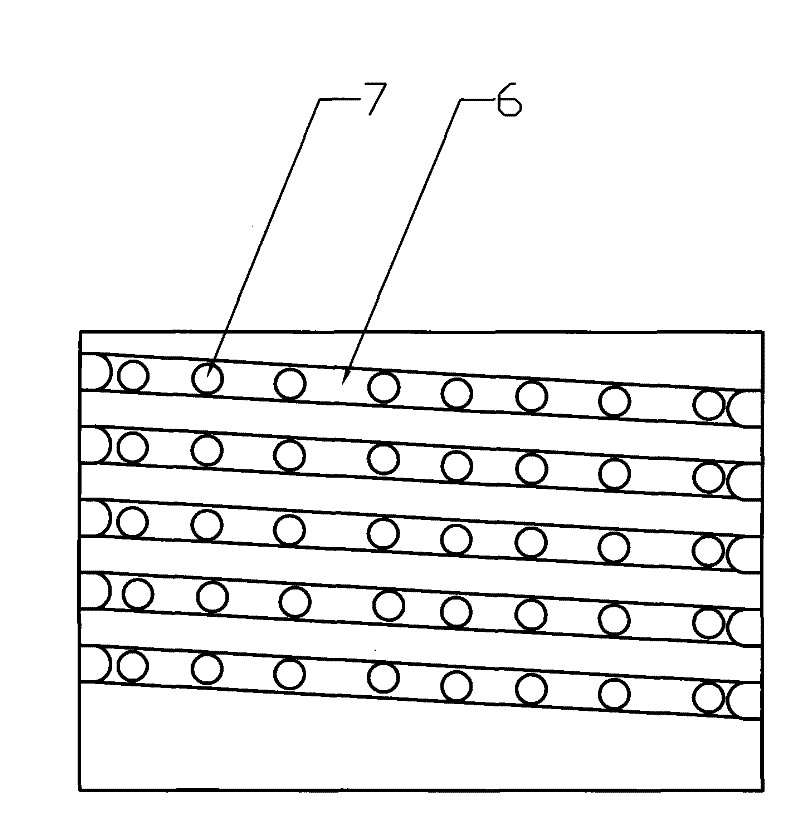

[0017] according to figure 1 , figure 2 and image 3 As shown, the aluminizing furnace includes an outer body 1, and an electric furnace liner 2 is arranged inside the outer body. The outer body 1 and the electric furnace liner 2 shrink inwardly to form a ladder shape, and the distance from the upper end of the electric furnace liner to the upper end of the outer body is 136mm. The insulation cotton 3 is filled between the outer body and the electric furnace liner. The outer surface of the electric furnace liner is provided with spirally distributed electric furnace wire grooves 6, the width of which is 17 mm, and heat transfer holes 7 with a diameter of 12 mm are evenly arranged in the grooves, and the electric furnace wires are wound on the electric furnace wire grooves 6. The diameter of the electric furnace wire is 16 mm. After winding, the joint of the electric furnace wire is connected to the temperature controller 4 through a wire. An electric thermocouple 5 is also ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com