A ladle baking device with adjustable lifting of the outer ring of the cover

A technology of baking device and regulating device, which is applied in the direction of casting melt container, metal processing equipment, casting equipment, etc. It can solve the problems that the burner cannot move up and down, the temperature distribution of the ladle is uneven, and the baking quality is poor. The quality and baking quality are improved, the upper and lower temperatures are uniform, and the effect of uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] For further understanding of the present invention, now describe in conjunction with accompanying drawing:

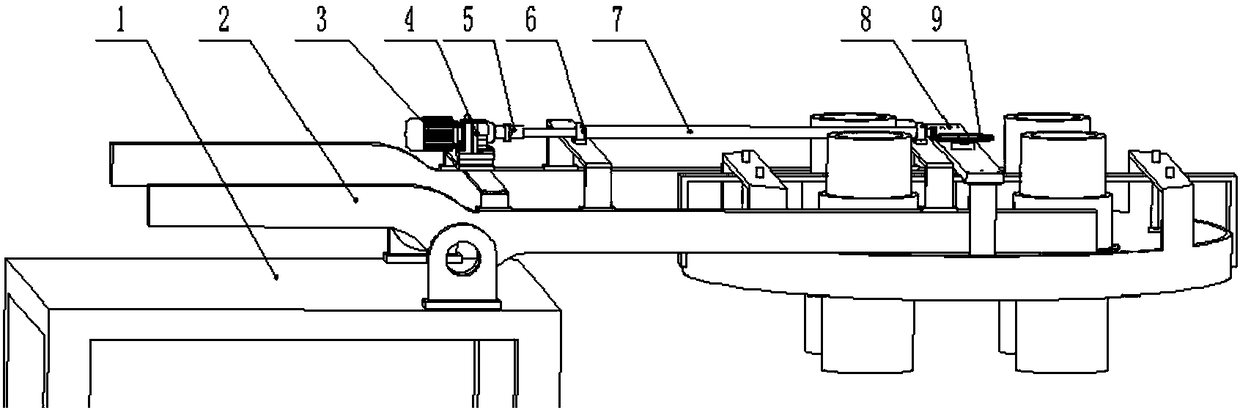

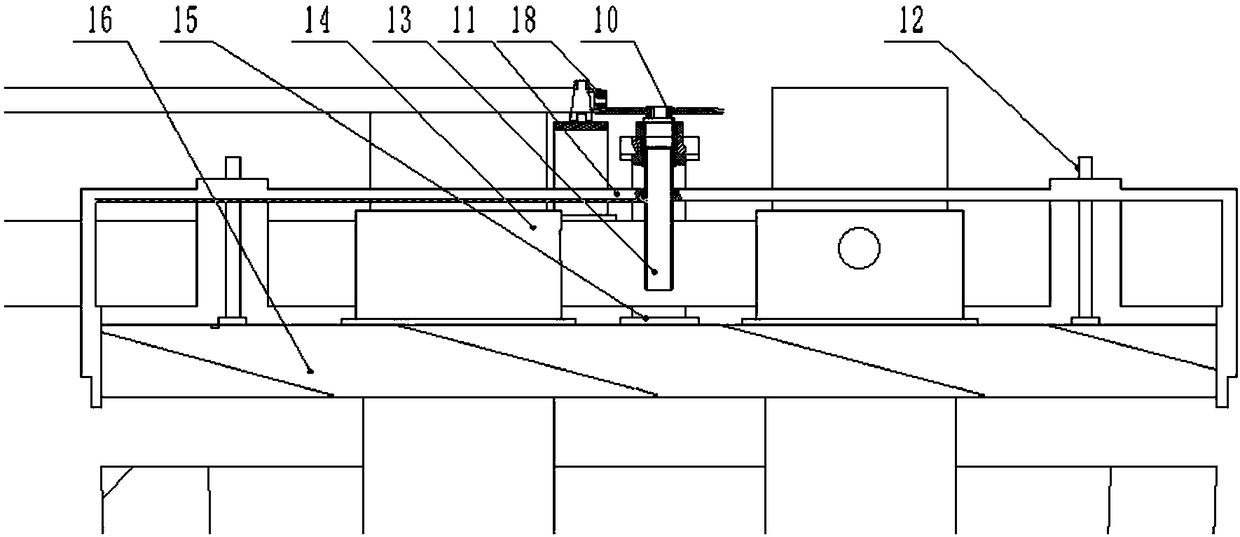

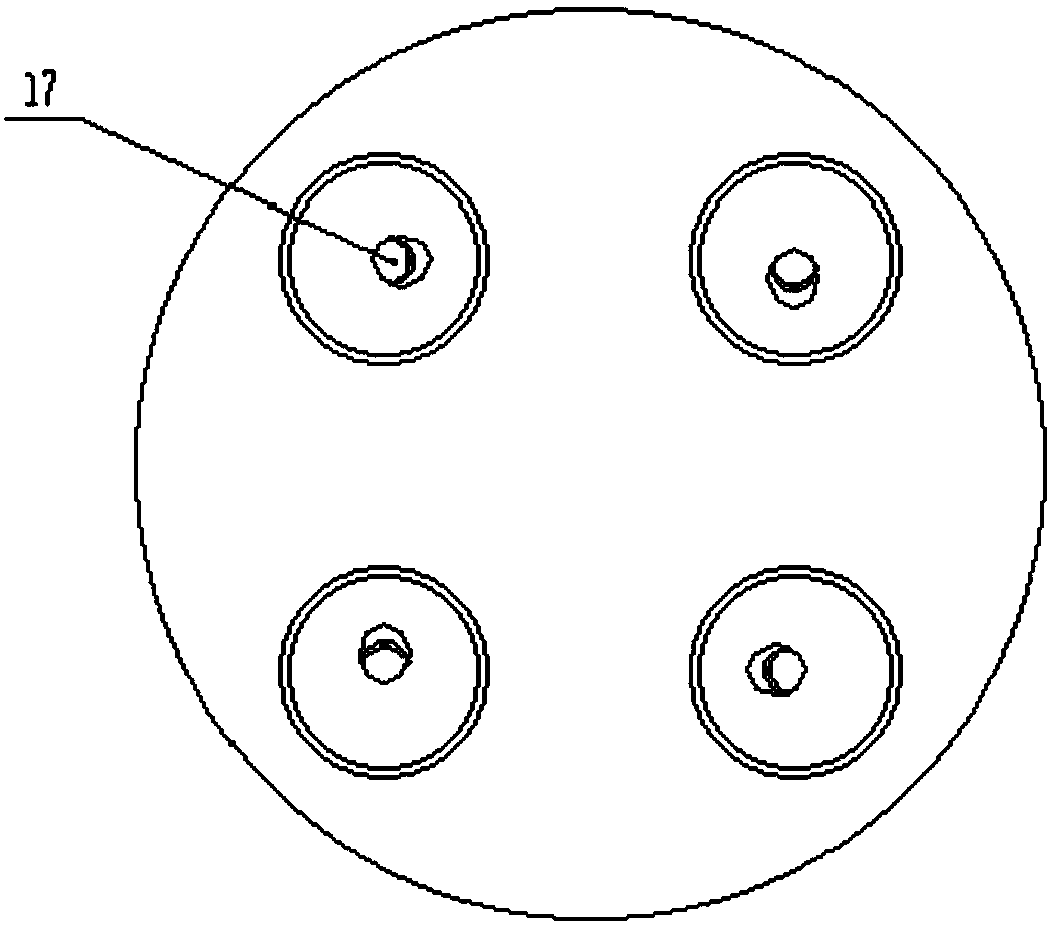

[0024] like figure 1 As shown, the ladle baking device with adjustable lift of the outer ring of the cover of the present invention includes a frame 1, a rotating arm 2, a cover 16, a regenerative burner 14 and an adjustment device for the outer ring of the cover; One end of the rotating arm 2 is connected to the frame 1 by a pin, and the other end is fixedly arranged on the upper surface of the cover 16; the adjusting device for the outer ring of the cover includes a screw 13, an outer ring 11 of the cover, a cover 16 and a motor 3; The cover outer ring 11 is arranged between the cover 16 and the support plate 8, and the cover outer ring 11 is slidingly connected with the outer cylindrical surface of the cover 16, and the threaded hole provided in the middle position of the cover outer ring 11 is threaded with the screw rod 13. Connect to form a lead screw nut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com