Method and special equipment for recycling to produce fuel

A technology of organic waste and special equipment, used in special forms of dry distillation, petroleum industry, coke ovens, etc., can solve the problems of non-continuous normal operation, cumbersome process and equipment, uneven heating of organic waste, etc. The effect of small internal volume and reduced replacement frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

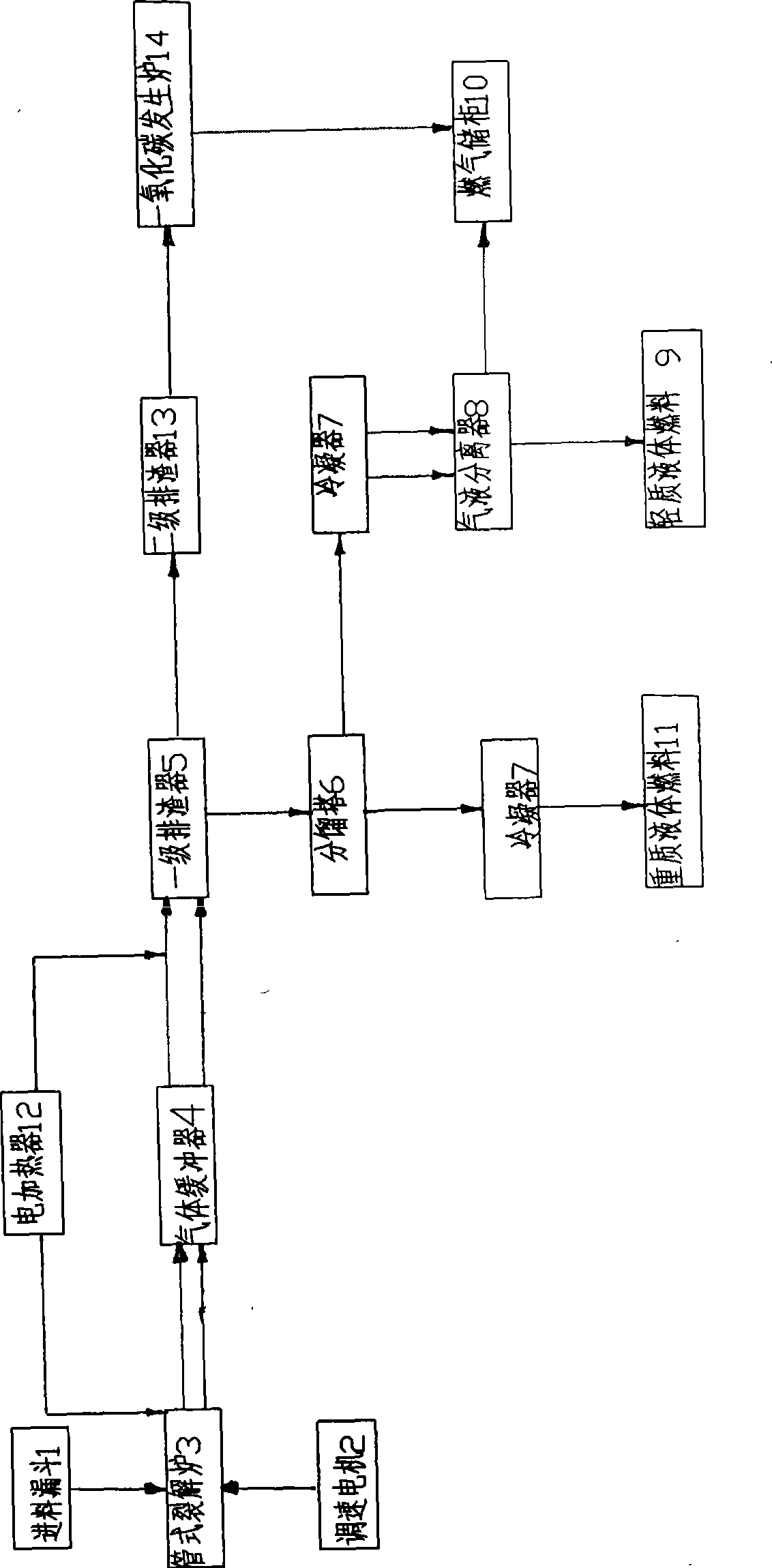

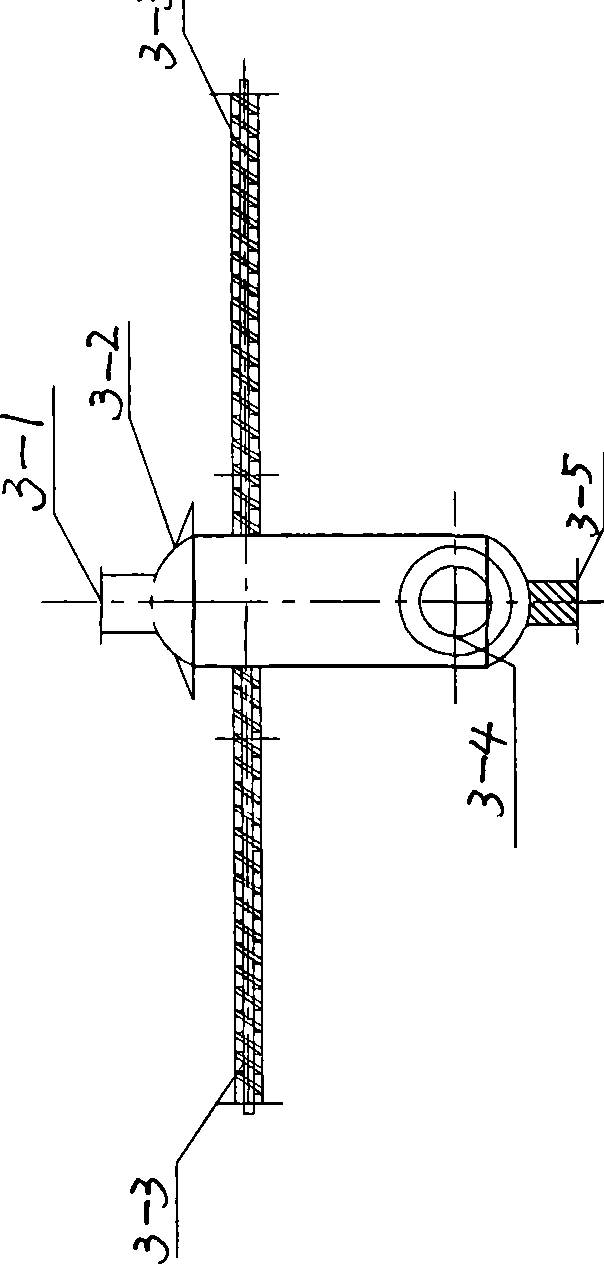

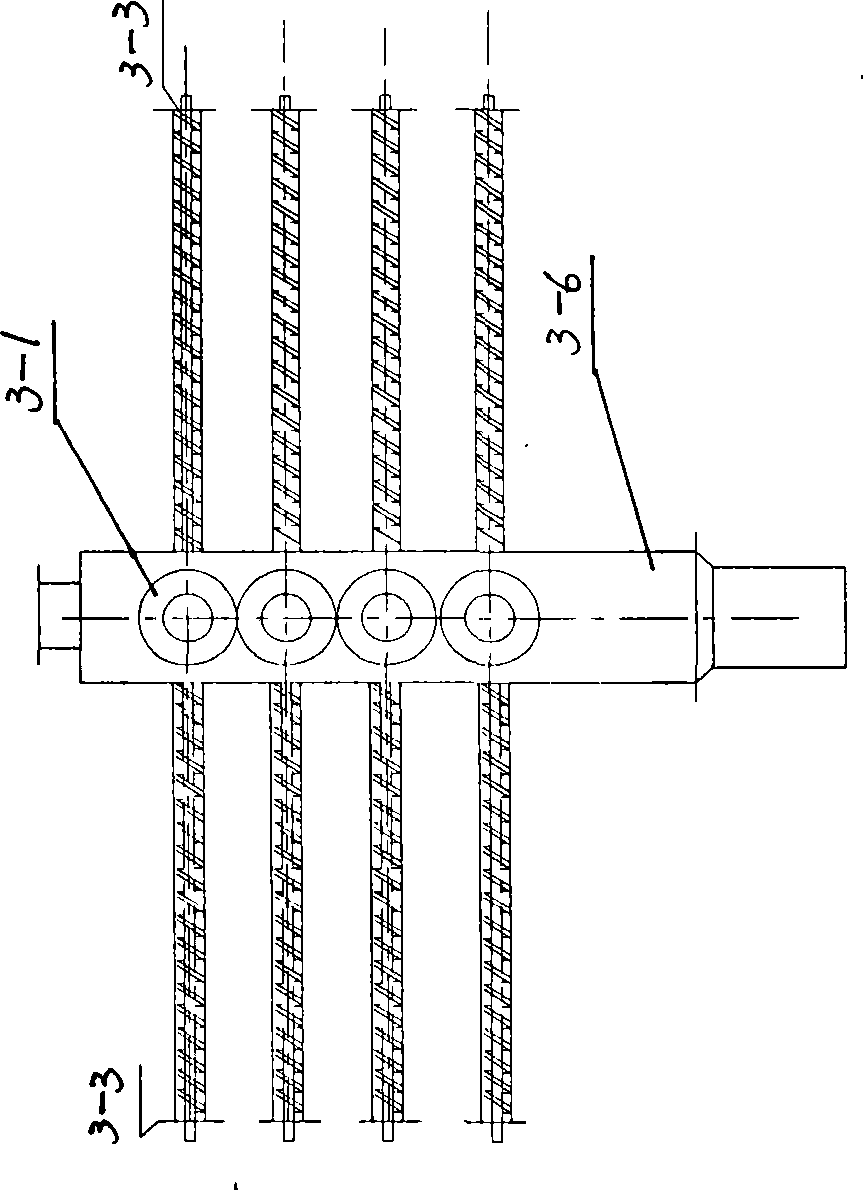

[0019] See figure 1 , Separate the domestic garbage to remove metal and inorganic matter, separate the organic garbage, and pass the organic garbage from the feed hopper 1 through the conveying tubes 3-3 on both sides of the tubular cracking furnace 3 to the furnace to the collector 3-6 In the middle push, the advancing speed is 60~65 rpm, heating and depolymerizing at the temperature of 220~240℃, the spiral hinge rod is installed in the conveying tube 3-3, and the material is expanded to the middle of the cracking furnace controlled by the speed regulating motor 2. The radial concentrators 3-6 are advanced, and the electric heating device 12 respectively heats up and heats the conveying tube, the cracking furnace concentrator and the concentrating pipeline between the primary slag discharger.

[0020] The gas material depolymerized by the cracking furnace first enters the gas buffer 4, and the inner wall of the buffer 4 is provided with staggered baffles. The gas flow direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com