Heavy duty dumper

A technology of unloading car and guide chute, applied in the direction of conveyor, mechanical conveyor, conveyor objects, etc., to achieve the effect of prolonging service life, simple structure and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

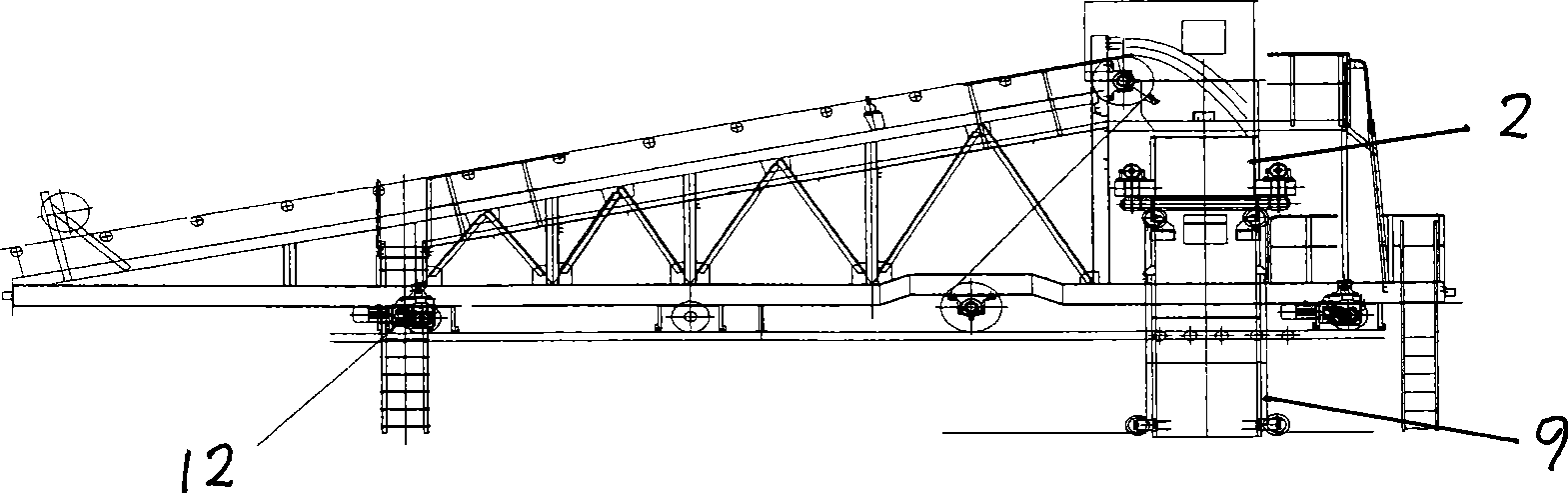

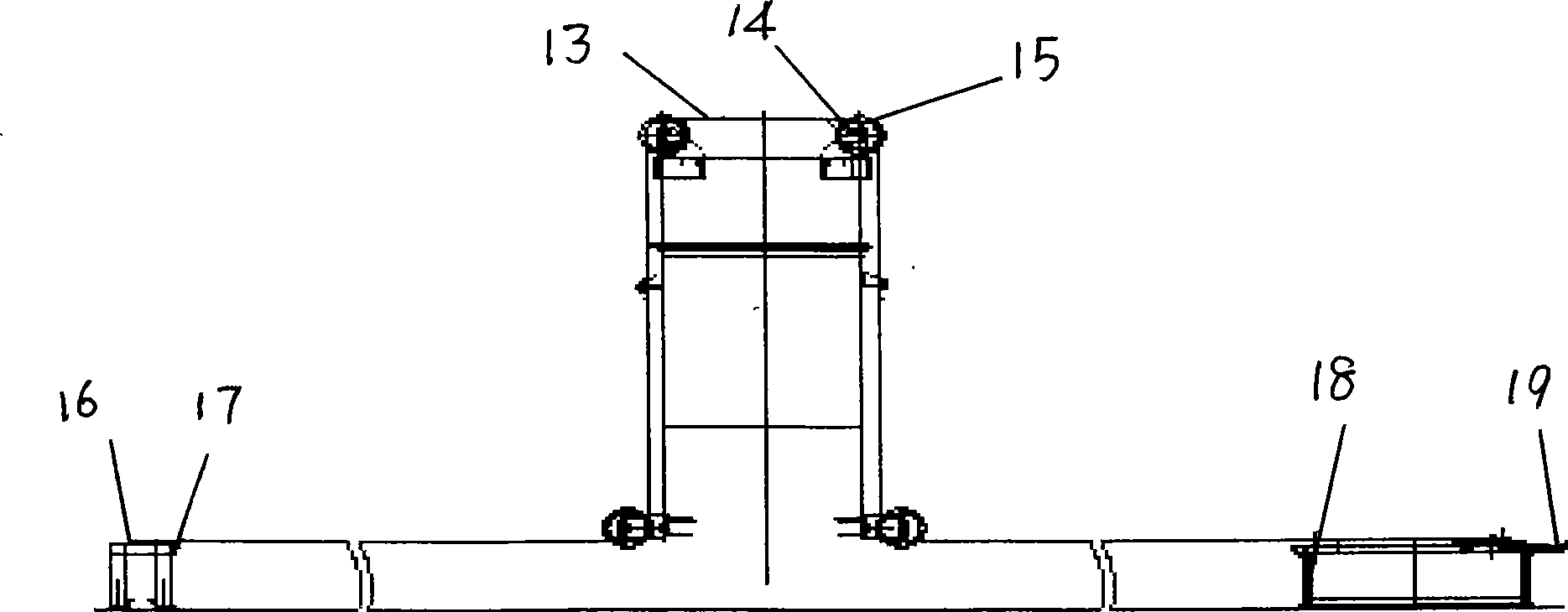

[0011] It has a driving traveling device 12, a main belt, and two side chutes 11 connected to the funnel 2, and directly below the funnel are a material guide chute, a material receiving buffer device and a main belt 10, see figure 2 , the said trough has a wear-resistant liner 4 on the inner side of the side plate 3 of the trough to prevent the material from scratching the side plate of the trough, and there is an adjustable rubber at the lower end of the side plate of the trough Plate 5, the adjustable rubber plate 5 is fixed by the pressure plate 6, and the rubber plate 5 can be adjusted downward at any time to ensure the sealing of the lower part and prevent the material from leaking here. The buffer device has a buffer roller frame body 8 and a buffer roller group 7. A rubber ring is installed on the surface of the buffer roller. When the material needs to be unloaded on the main belt, the material falls on the buffer device through the funnel and the guide groove. , to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com