Idler roller driving belt type conveyor

A belt conveyor and driving belt technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of high cost, high maintenance rate and complex structure of conveyor belts, and reduce investment costs and operation. Smooth and maintenance-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

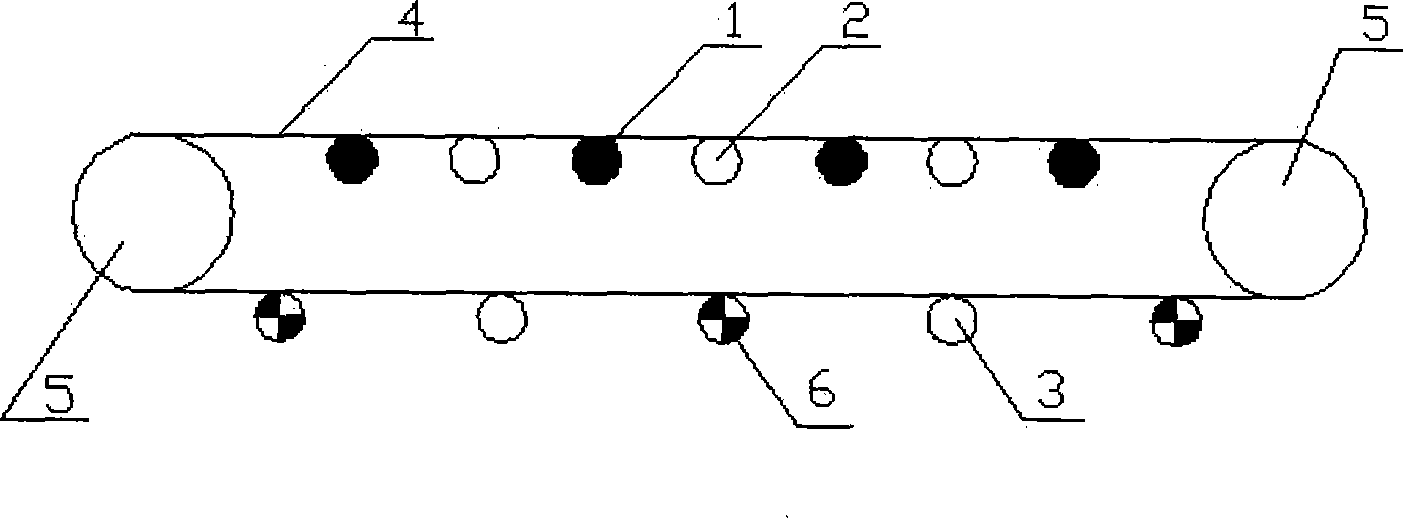

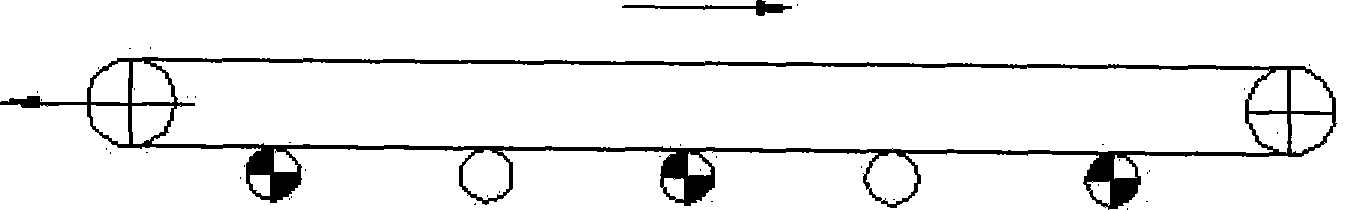

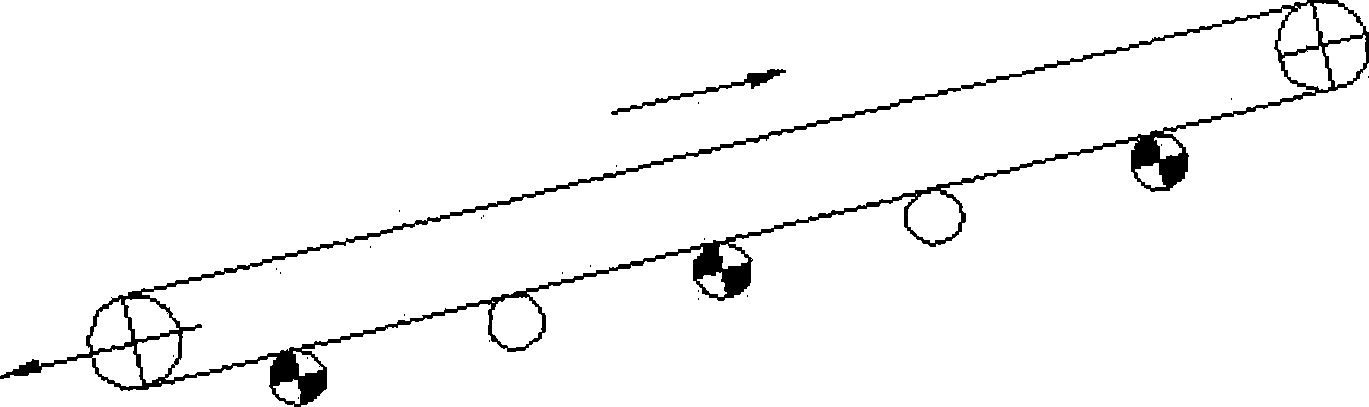

[0033] See figure 1 , idler-driven belt conveyor, including reversing roller 5, load idler 2, load-drive idler 1, return idler 3, return drive idler 6, conveyor belt 4, structural support, electrical control system, the belt The belt conveyor adopts multiple load-bearing driving rollers 1 to directly drive the conveyor belt, and the specifications, speed and quantity of the required load-bearing driving rollers are designed according to the carrying capacity requirements of the belt conveyor; the belt conveyor is designed according to the longitudinal tension of the conveyor belt. , to determine whether return drive rollers need to be installed with return drive rollers, the number of which is determined according to the design requirements of the longitudinal tension of the conveyor belt, and all load drive rollers 1 and return drive rollers 6 are connected in series, and are controlled by an electrical control system synchronized movement.

[0034] Roller-driven belt convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com