Double-up-stroke detrusion regulating mechanism of powder shaping mill

A technology for adjusting mechanisms and forming machines, applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of inability to control movement in two directions, and inability to process powder products, etc., to achieve height increase, fast pressing speed, and The effect of short modulus distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

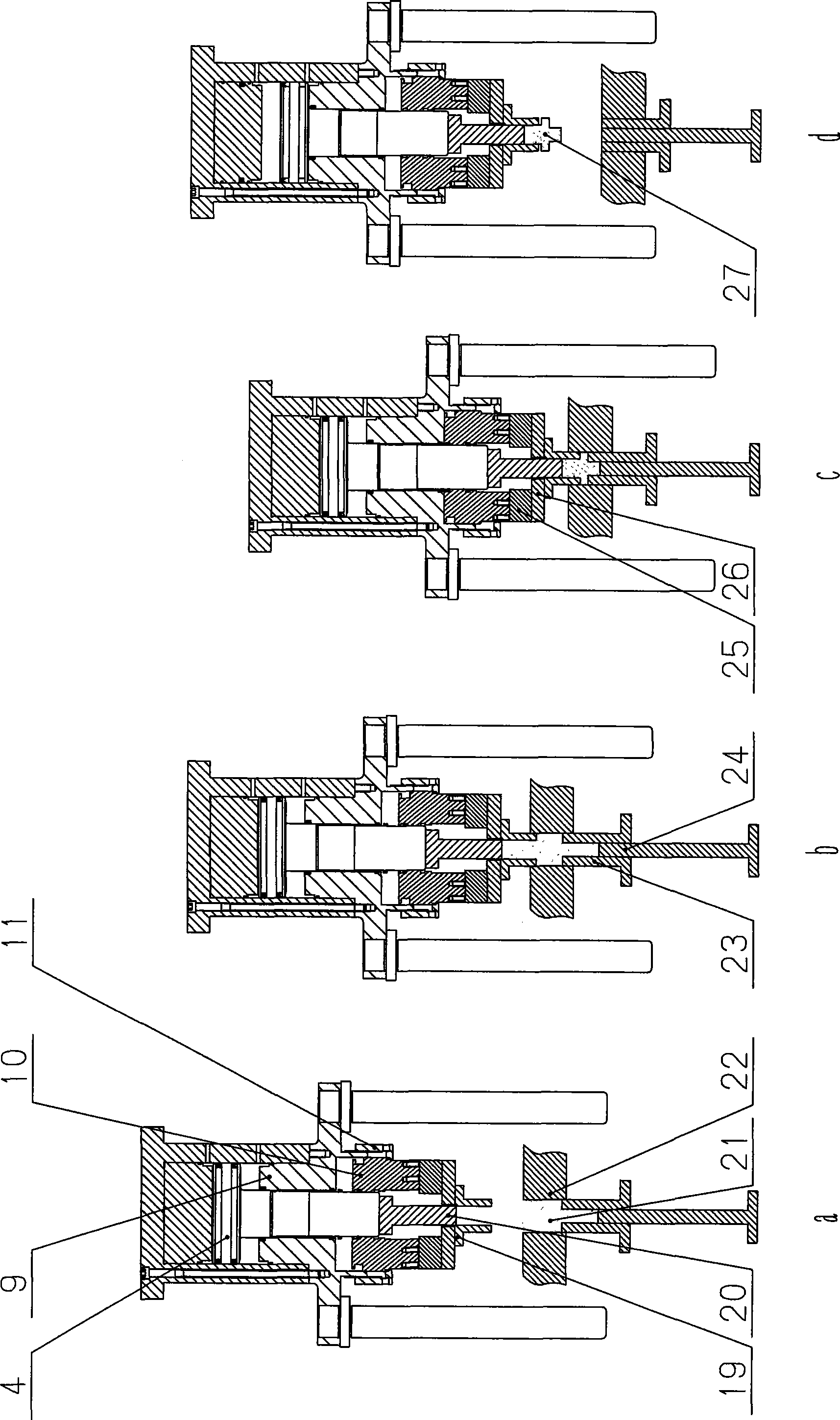

[0011] Embodiments of the utility model will be further described below in conjunction with the accompanying drawings.

[0012] The two-way adjustment mechanism of double upper punch and outer punch is composed of a fixing device and an adjusting device consisting of an inner punch cylinder, a sealing seat, and an air flushing guide seat.

[0013] There is an air guide tube 17 on the side wall of the air flushing guide seat 9, and the sealing seat 6 and the inner flushing cylinder body 1 are fixed with screws on the step surface in the middle of the upper surface, and the lower end of the outer surface is connected with the adjustment nut 11, and the outer flushing seat 10 slides Fitted in the air-rushing guide seat 9, the cylinder 8 is also fixed with screws on both sides of the upper surface, an upper air inlet 18 and a lower air inlet 16 are arranged on the upper and lower ends of the cylinder, and the upper air inlet 18 of the two cylinders is connected together , the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com