Production chain of instant dry rice noodles and technique for producing the same

A production line and rice noodle technology, applied in food preparation, food science, application, etc., can solve problems such as inaccuracy in place, low food yield, and inability to achieve mass production, and achieve the effect of ensuring production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

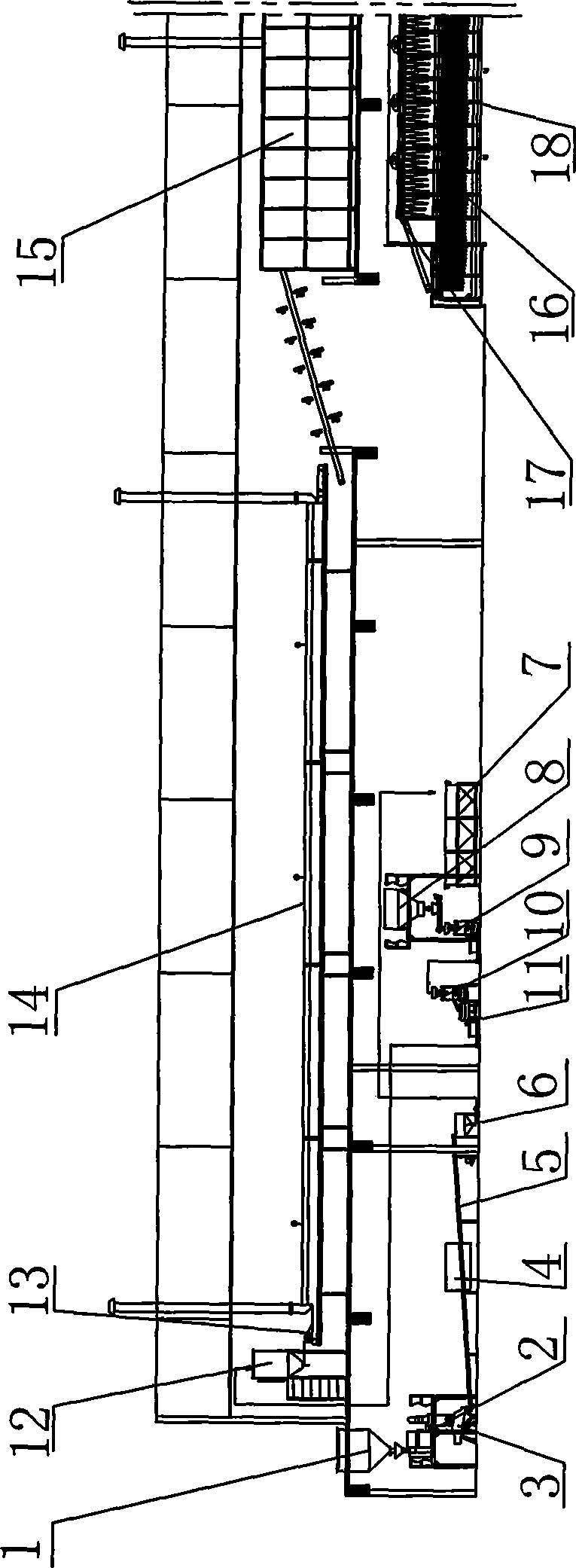

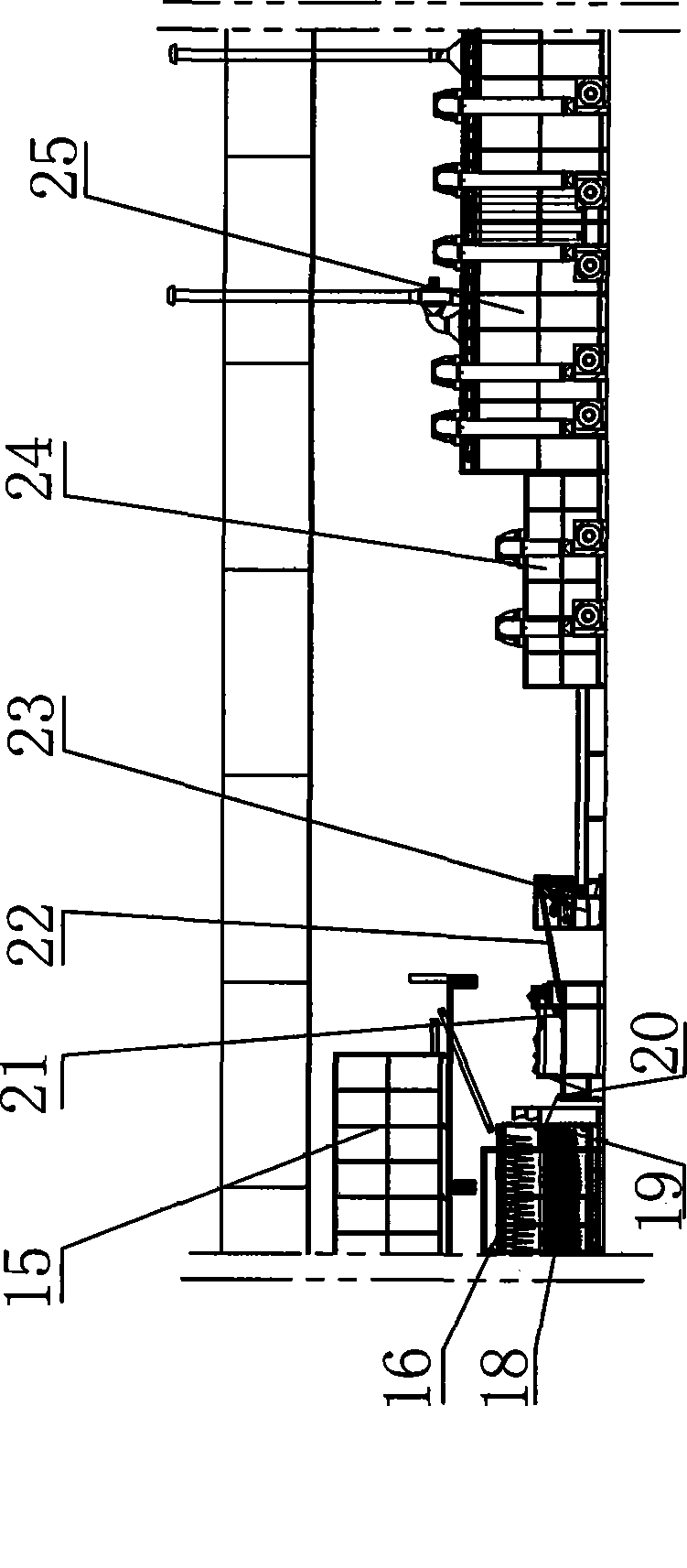

[0055] Such as Figures 1 to 5 The instant dried rice noodles production line shown includes a rice bucket 1 for conveying materials, a wind jet rice mill 2, a specific gravity sand remover 3, a rice color sorter 4, a rice conveyor 5, a rice pump 6, and a jet washing rice Machine 7, Water and Rice Separation Tank 8, Primary Refiner 9, Secondary Refiner 10, Pulp Screening Machine 11, Pulp Storage Machine 12, Stirring Automatic Pulping Machine 13, Steaming Machine 14, Vermicelli Pre-drying Machine 15. Vermicelli freezer 16, primary recovery machine 17, secondary recovery machine 19, roller transition conveyor 20, shredding machine 21, vermicelli conveyor 22, quantitative cutting machine 23, automatic setting machine 24, dryer 25, Air cooler 26 and packaging conveyor 27.

[0056] Such as Figure 6 As shown, wherein, the jet rice washing machine includes a water supply motor 503, a rice washing motor 504, a first rice washing tank 506, a second rice washing tank 507, and a third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com