Method and equipment for preparing difluoromonochloroethane by photochemical catalyst

A technology of difluoro-chloroethane and difluoroethane, which is applied in the field of photocatalytic production of difluoro-chloroethane, can solve the problems of large equipment footprint, not a good one, and many by-products, and achieve The effect of small footprint, less material back-mixing, and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

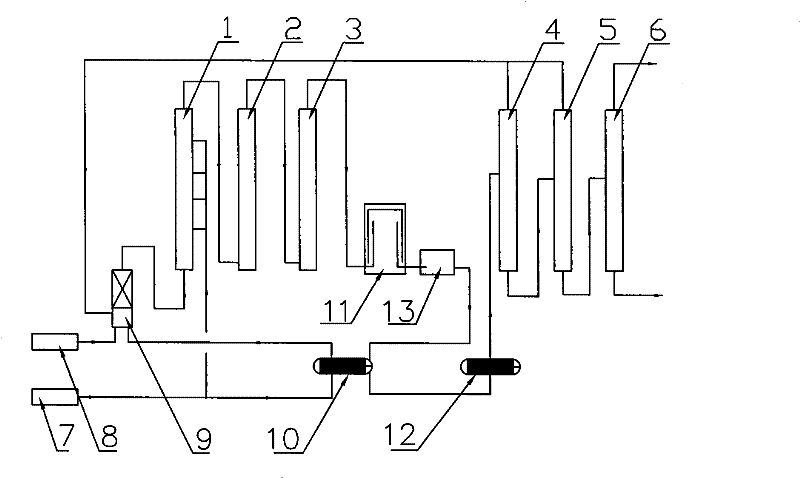

Method used

Image

Examples

Embodiment 1

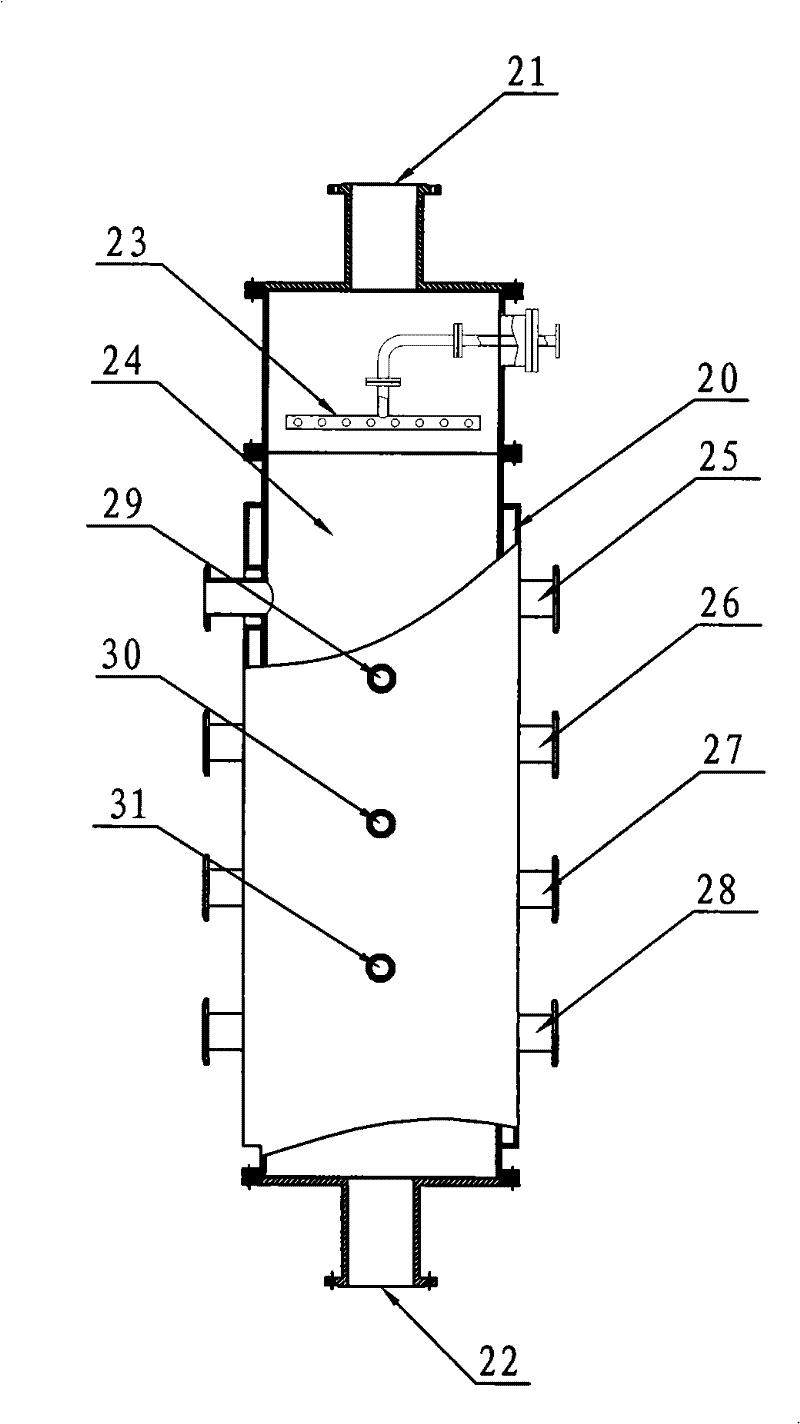

[0041] see figure 1 , The photocatalytic reactor of the present invention includes a cylinder with a heat exchange jacket 20 on the outer wall and a polytetrafluoroethylene-lined inner wall.

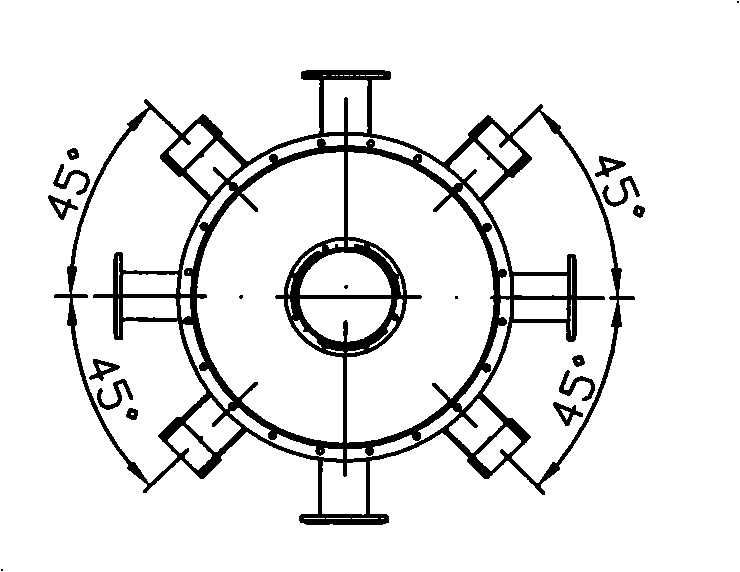

[0042] The top of the cylinder is provided with a material outlet 21, the bottom of the cylinder is provided with a material inlet 22, and the top of the cylinder is provided with a spray device 23 made of polytetrafluoroethylene. The part below the spray device 23 is assembled by connecting up and down with four tower sections (for convenience, figure 1 Only one tower section is drawn, and the other three sections are omitted), figure 1 The middle tower section 24 is provided with four ultraviolet lamps arranged up and down, and the ultraviolet lamp is covered with a protective quartz glass tube, such as the quartz glass tube 25, the quartz glass tube 26, the quartz glass tube 27 and the quartz glass tube 28 in the figure .

[0043] The reactor has four tower sections, each of which ...

Embodiment 2

[0057] Prepare difluoro-chloroethane according to the process and equipment of the embodiment. The molar ratio of chlorine gas and difluoroethane is 1:1. After gasification, it is mixed with a mixer, heated to 40°C and entered into a photocatalytic reactor for reaction. The flow rate of the mixed gas of chlorine and difluoroethane in the photochemical reactor is 0.085m / s, and the reaction time is 100s. Difluoroethane, the amount of material sprayed into the tower is 10% of the amount of difluoroethane entering the mixer. The flow rate of cold water sprayed into the top of the reactor is 2m 3 / h.

[0058] Samples were taken from the top of the photocatalytic reactor, washed with alkali, dried, and then analyzed by gas chromatography. The components were difluorochloroethane: 89.55%, difluorooxane: 8.08%, unknown component 1: 1.34%, Unknown component 2: 0.8%, others: 0.23%, indicating that the method and reactor of the present invention have a high single-pass conversion rate ...

Embodiment 3

[0061] Prepare difluoro-chloroethane according to the process and equipment of the embodiment. The molar ratio of chlorine and difluoroethane is 1:1. After gasification, it is mixed with a mixer, heated to 55°C and entered into a photocatalytic reactor for reaction. The flow rate of the mixed gas of chlorine and difluoroethane in the photochemical reactor is 0.085m / s, and the reaction time is 90s. Difluoroethane, the amount of material sprayed into the tower is 10% of the amount of difluoroethane entering the mixer. The flow rate of cold water sprayed into the top of the reactor is 2m 3 / h.

[0062] Samples were taken from the top of the photocatalytic reactor, washed with alkali, dried, and then analyzed by gas chromatography. The components were difluoro-chloroethane: 85.95%, difluoro-alkane: 10.64%, unknown component 1: 1.74%, Unknown component 2: 1.67%, indicating that the method and reactor of the present invention have a high single-pass conversion rate and few by-prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com