Laser welding method of electrode collar in artificial cochlea and platiniridium wire

A technology of laser welding and electrode ring, which is applied in the direction of laser welding equipment, welding equipment, welding equipment, etc., can solve the problem of small electrode ring, and achieve the effect of fast welding speed, high welding fastness and small welding spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

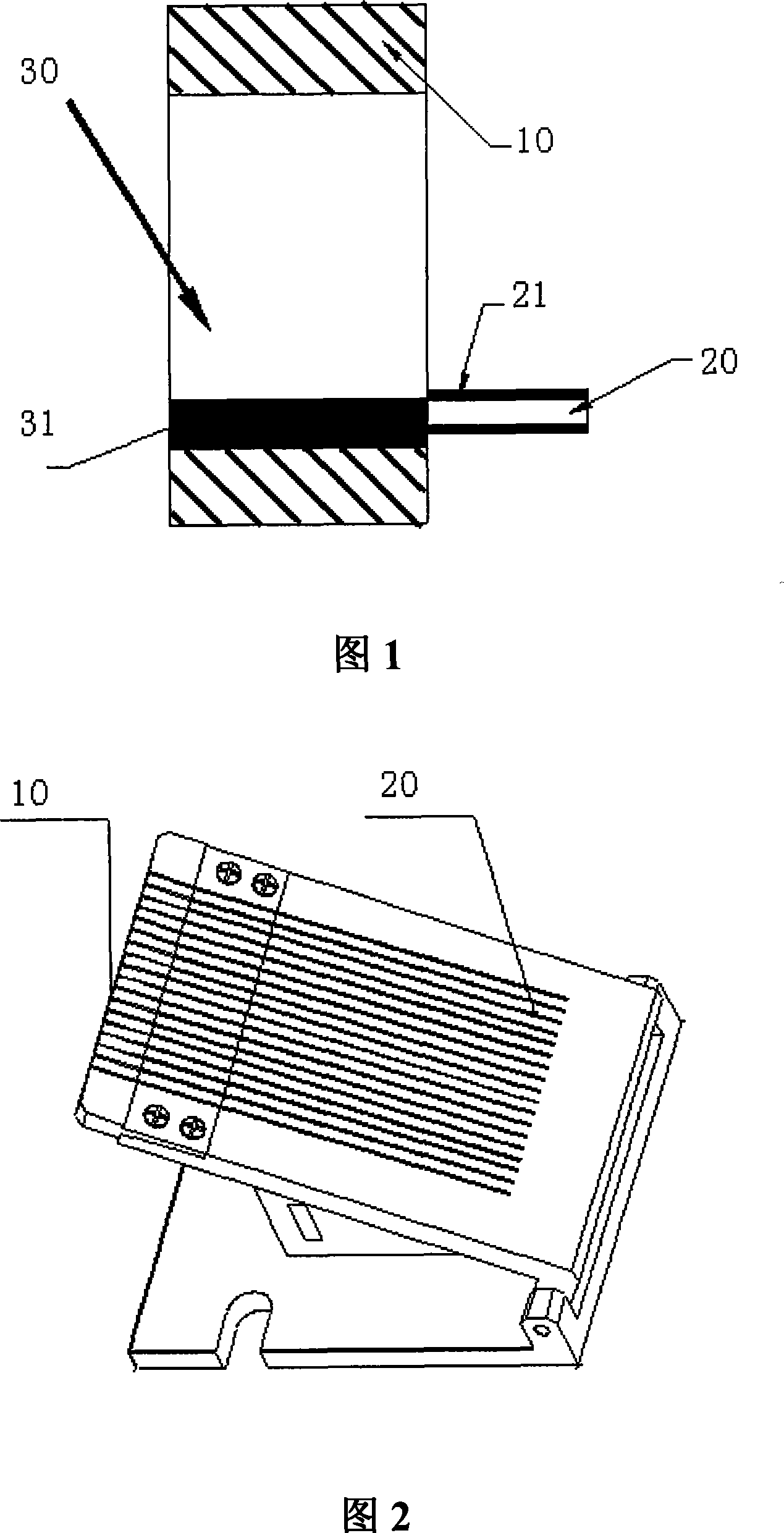

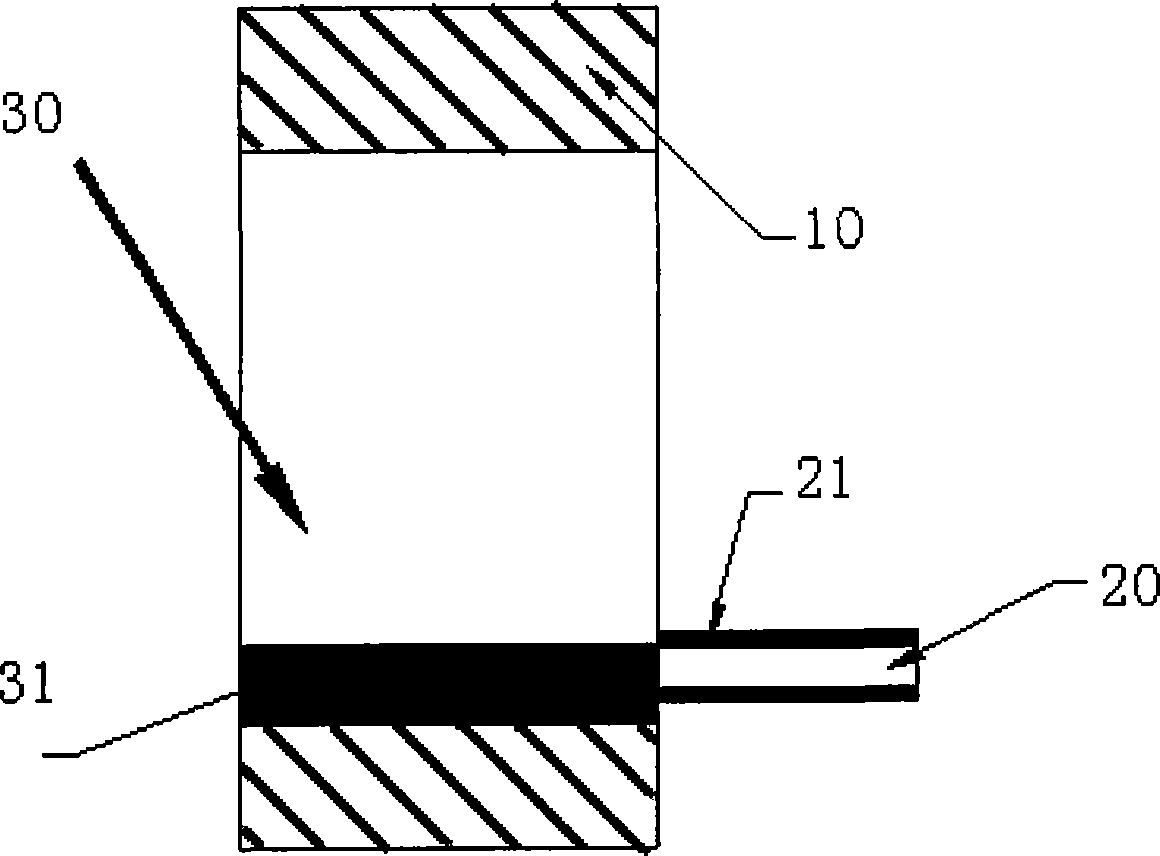

[0016] It can be seen from Fig. 1 that: the platinum iridium wire 20, the insulating coating 21, the laser shot direction 30, and the solder joint 31 in the figure.

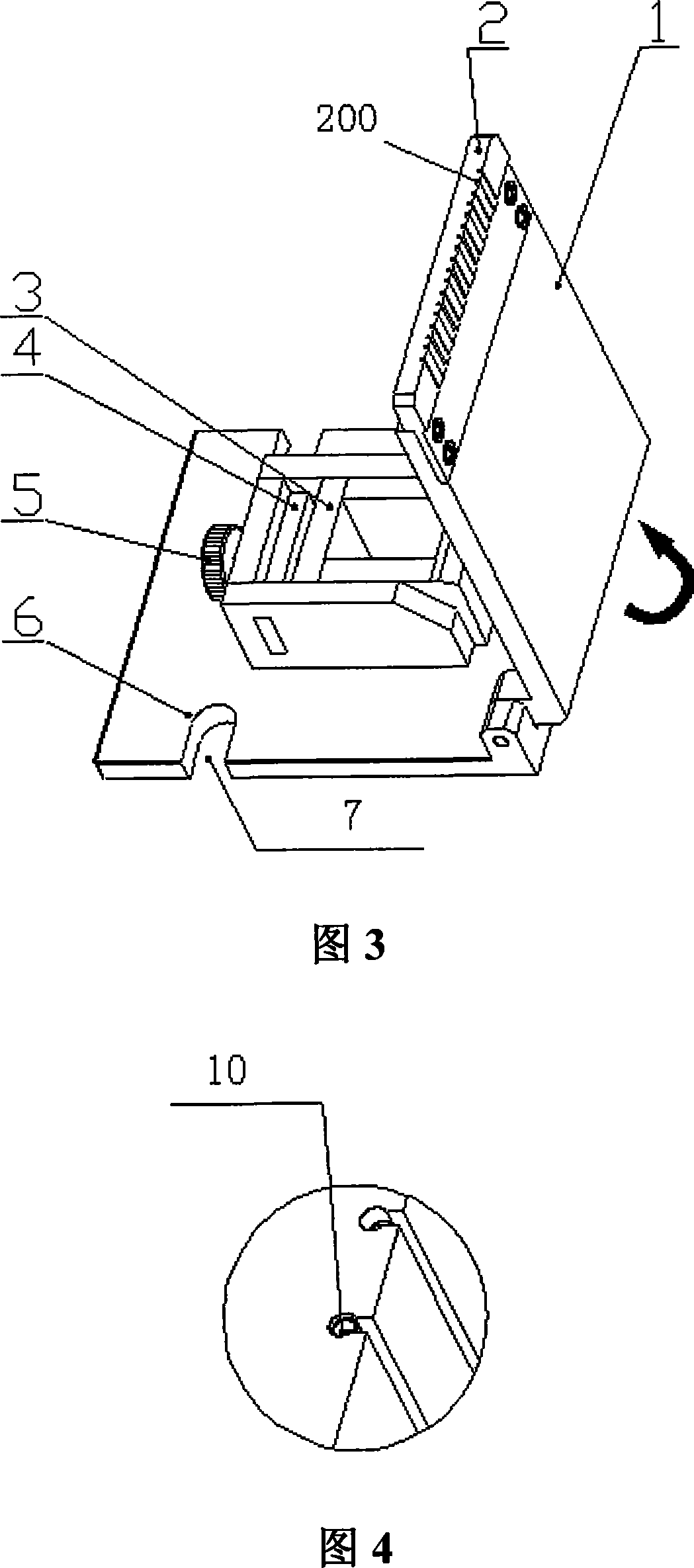

[0017] It can be seen from Figure 2, Figure 3, and Figure 4 that the present invention is implemented through the following steps:

[0018] Fix the jig as a whole on the laser welding workbench, put a platinum ring 10 into the positioning hole 200 of the electrode ring positioning plate 2, the platinum iridium wire 20 passes through the middle of the platinum ring 10, adjust the upper plate 1 of the welding jig, And fix the adjustment slider 3 to fix the angle between the upper plate 1 of the welding jig and the bottom plate 6 of the welding jig;

[0019] Make the laser weld the platinum ring 10 and the platinum iridium wire 20 together at a reasonable incident angle; the laser uses YAG seri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com