Preparation method of sodium carboxymethyl cellulose for food

A technology of sodium carboxymethyl cellulose and cellulose, which is applied in the field of polymer chemistry, can solve the problems of poor performance of cellulose pulp or wood pulp cellulose, high price of refined cotton raw materials, poor product replacement uniformity, etc., and achieves preparation The method is simple, the operation is convenient, and the effect of reducing the total production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

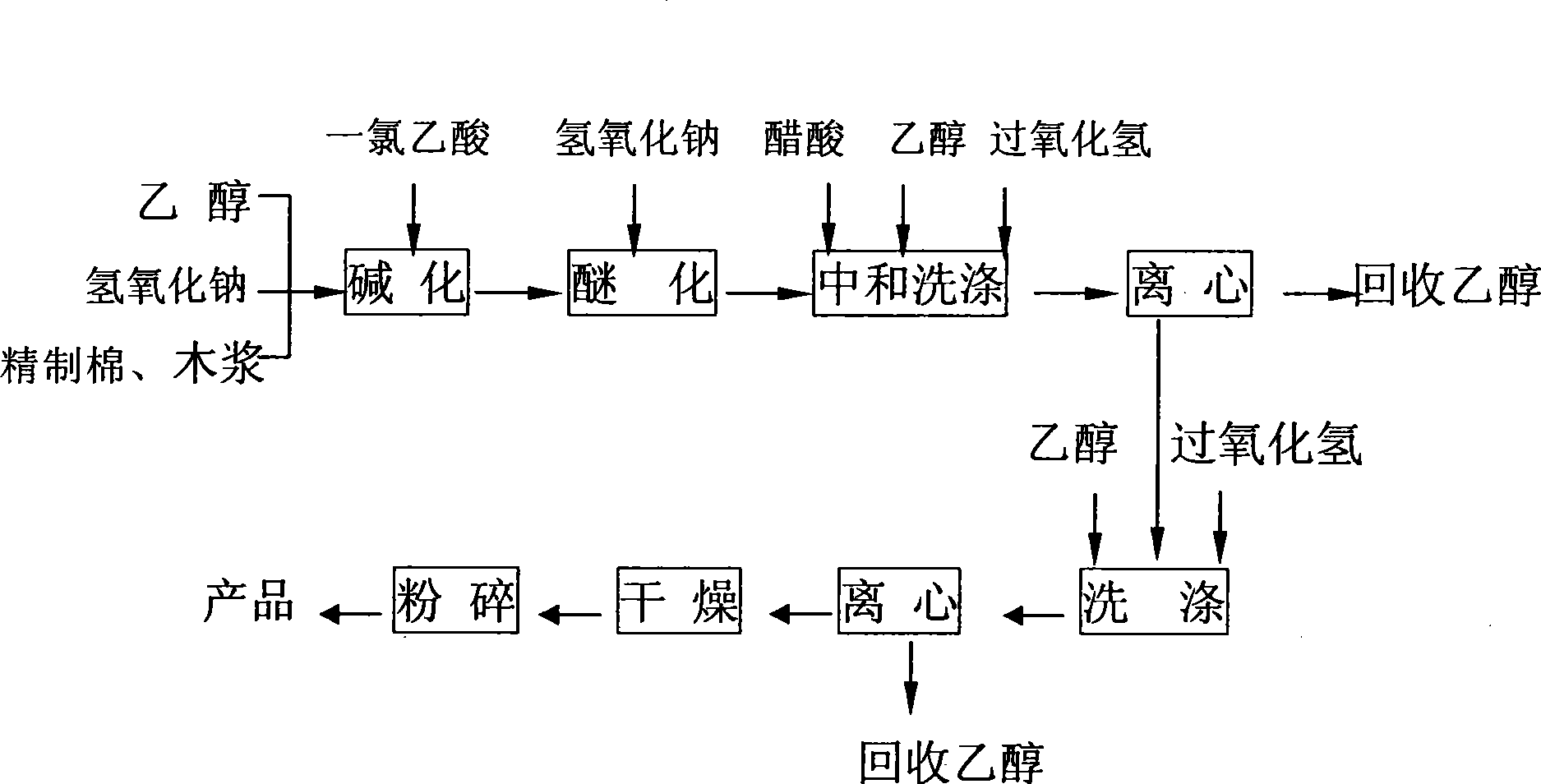

Method used

Image

Examples

Embodiment 1

[0023] When the temperature of the kneader is 30°C, 30 parts of wood pulp and 70 parts of refined cotton with an average degree of polymerization of 300 are uniformly added to 136 parts of 47% aqueous sodium hydroxide solution and 250 parts of 96% (volume) ethanol in 20 minutes. Add 140 parts of 65% monochloroacetic acid ethanol solution slowly within 40 minutes, then add 34 parts of 47% sodium hydroxide aqueous solution evenly within 10 minutes, and slowly heat up to 78°C , etherification reaction under stirring conditions for 40 minutes, cooling and discharging; 11 parts of 20% acetic acid was added dropwise to neutralize the remaining sodium hydroxide in the system, washed with 2000 parts of 76% (volume) ethanol aqueous solution for 40 minutes, and 4 parts of 27.5% aqueous hydrogen peroxide, centrifuged to separate aqueous ethanol, and the centrifuged material was washed again with 3000 parts of 70% (volume) aqueous ethanol for 45 minutes, and the aqueous ethanol that was se...

Embodiment 2

[0028] When the kneader is at a temperature of 20°C, 20 parts of wood pulp and 80 parts of refined cotton with an average degree of polymerization of 1000 are uniformly added to a mixed solution of 160 parts of 47% sodium hydroxide aqueous solution and 300 parts of 95% (volume) ethanol in 15 minutes 124 parts of 75% ethanol solution of monochloroacetic acid was slowly added within 60 minutes, and then 20 parts of 47% aqueous sodium hydroxide solution was evenly added in 5 minutes, and the temperature was slowly raised to 75°C, and stirred Conditional etherification reaction for 100 minutes, cooling and discharging; 34 parts of 15% acetic acid was added dropwise to neutralize excess sodium hydroxide, washed with 2500 parts of 74% (volume) ethanol aqueous solution for 45 minutes, and 27.5% hydrogen peroxide was added simultaneously 10 parts of aqueous solution, centrifuged to separate ethanol aqueous solution, the centrifuged material was washed with 2000 parts of 72% (volume) et...

Embodiment 3

[0033] When the kneader is at a temperature of 40°C, add 128 parts of 52% aqueous sodium hydroxide solution and 180 parts of 92% (volume) ethanol in 10 minutes to 40 parts of refined cotton with an average degree of polymerization of 2000 and 60 parts of wood pulp. In 20 minutes, slowly add 132 parts of 65% monochloroacetic acid ethanol solution, and then add 18 parts of 52% sodium hydroxide aqueous solution evenly in 10 minutes, and slowly heat up to 80 ° C Stir the etherification reaction for 70 minutes, cool down and discharge; add 4 parts of 25% acetic acid dropwise to neutralize excess sodium hydroxide, wash with 1800 parts of 70% (volume) ethanol aqueous solution for 45 minutes, and add 27.5% hydrogen peroxide at the same time 2 parts of aqueous solution, centrifuged to separate ethanol aqueous solution, the centrifuged material was washed again with 2200 parts of 72% (volume) ethanol aqueous solution for 35 minutes, centrifuged to separate ethanol aqueous solution, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com