Solar photovoltaic green-house for rearing tomatoes

A solar photovoltaic and tomato technology, applied in the field of solar photovoltaic greenhouses, can solve the problems of not involving the cleaning of the surface of solar cells, difficult to adjust the amount of solar radiation, unsuitable for large-scale popularization in rural areas, etc. Simple, large format effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

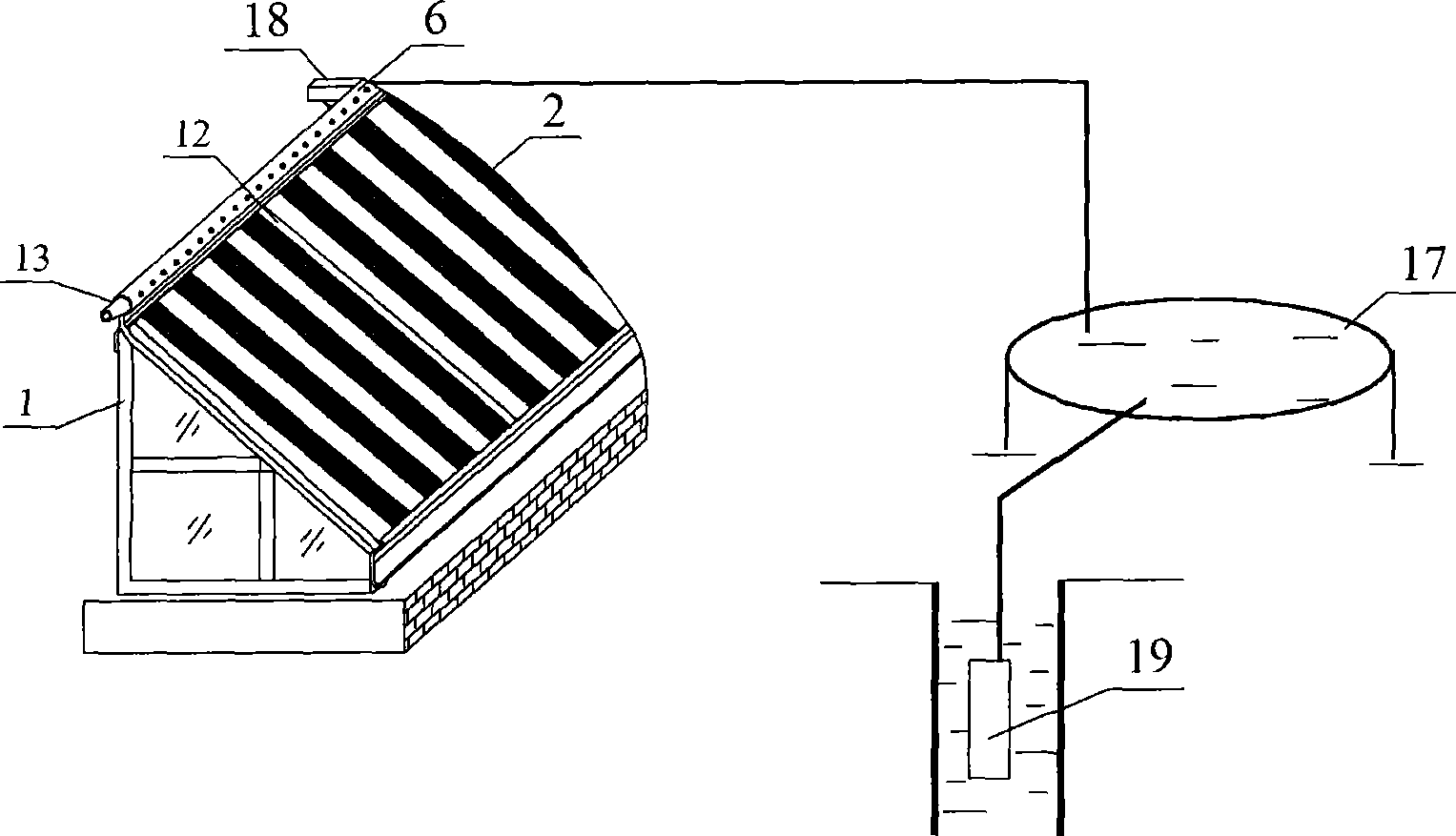

[0035] See figure 1As shown, the semi-slope solar photovoltaic greenhouse with an inclination angle of 35 degrees, a total of 300 amorphous silicon solar panels for solar cell module 2, and a designed peak voltage power of 6000 watts. The size of the solar panels is 350mm×1220mm, and the voltage of each 30V, current 1.25A. The light transmittance is 60%, and the design discharge depth is 50%. The roof of this embodiment is constructed of three half-slope roofs, each span is installed with 150 pieces of amorphous silicon solar cells, three battery core boards are a group with a string voltage of 90V, and the area of the battery components after PVC packaging is 1100mm×1220mm, 50 groups in parallel, parallel voltage 90V, current 62.5A, current 125A after confluence of two half-slope roof arrays, choose controller 150A. The main frame has a column every 4 meters, and a piece of white glass with a width of 1 meter is added between every 4 solar cell modules 2. The spacing betw...

Embodiment 2

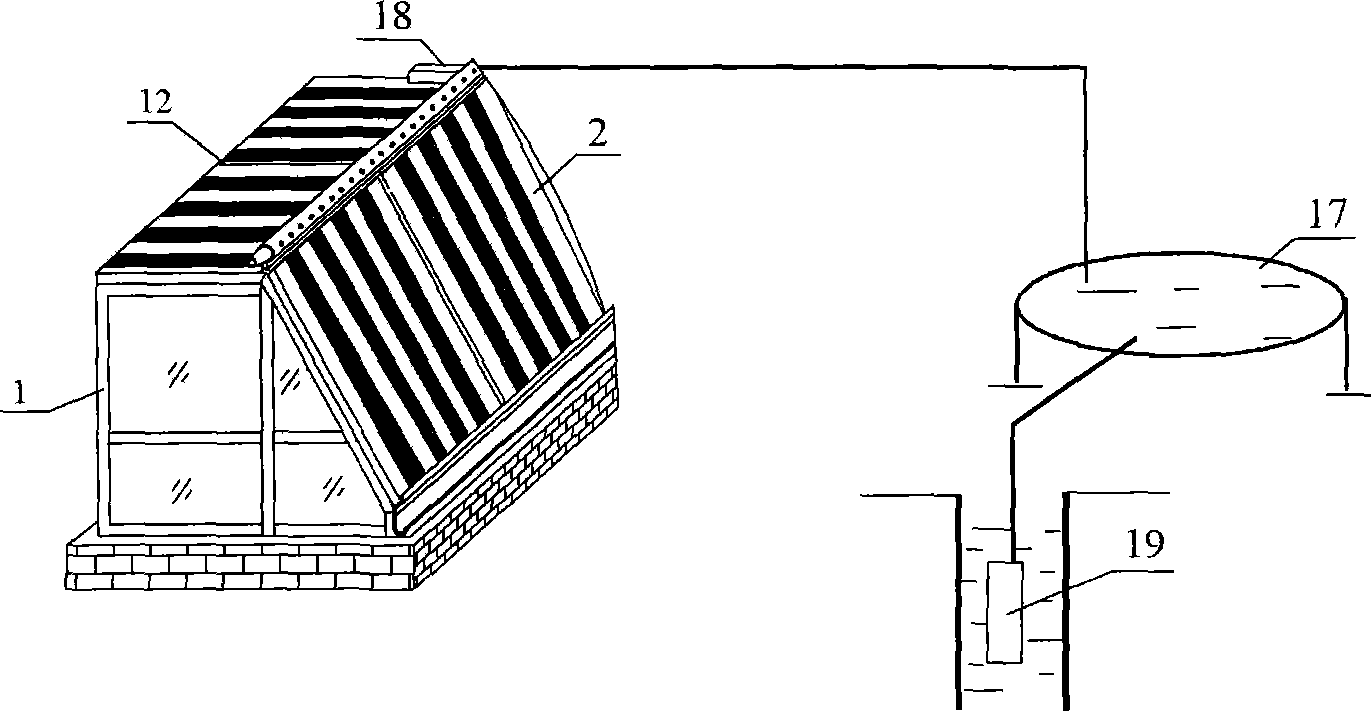

[0039] See Figure 14 , is the equivalent principle diagram of photovoltaic power generation in the present invention. Amorphous silicon solar cell modules can use a battery core plate with a model size of 350mm×1220mm, with a voltage and current of 30V and 0.8A, and a battery core plate with a model size of 707mm×1640mm, with a voltage and current of 40V and 1.25A. The parallel design peak voltage power is 8000 watts, and the design discharge depth is 50%. The roof structure of this embodiment is as Figure 1-a As shown, it is a half slope structure with a flat roof. The flat roof is packaged with a battery core board of 350mm×1220mm, and the half slope is packaged with a battery core board of 707mm×1640mm.

[0040] The greenhouse can also be composed of three roofs with a flat roof and half-slope structure. The flat roof is made of a 350mm×1220mm battery core board package and 525mm wide white glass laid at intervals, with a light transmittance of 60%; The surface is made...

Embodiment 3

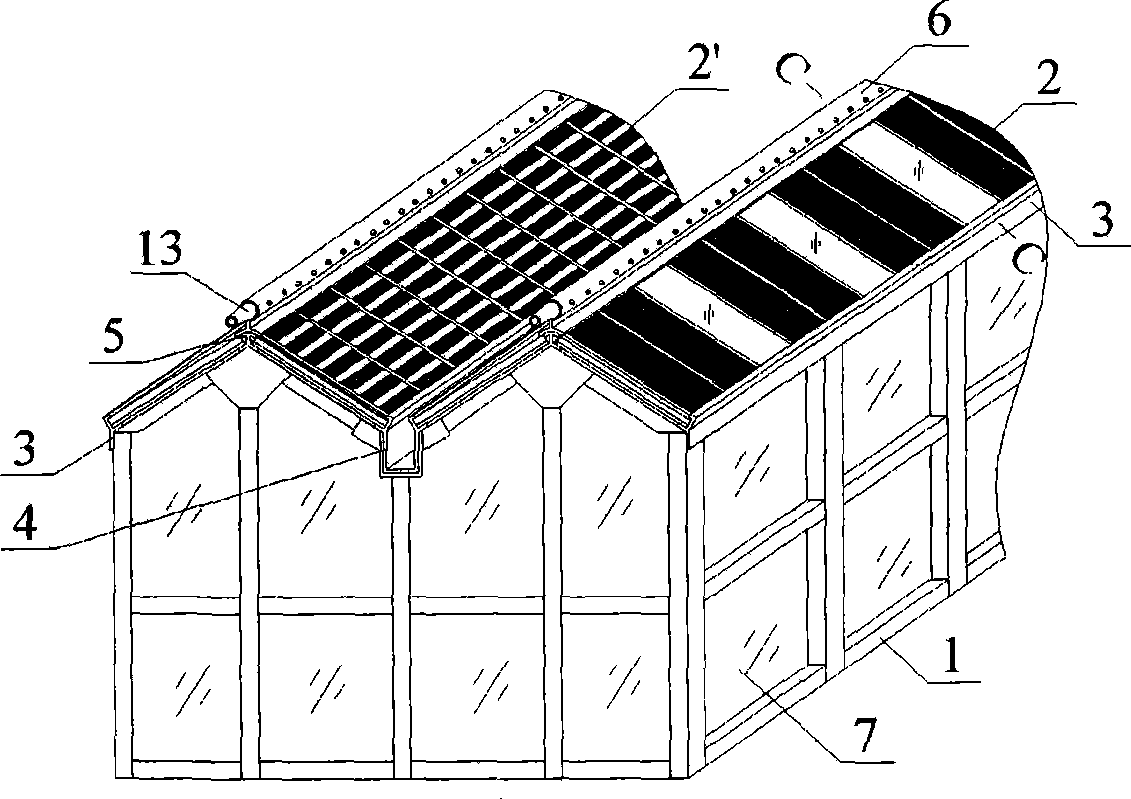

[0044] See figure 2 , image 3 and Figure 5 , the solar photovoltaic greenhouse includes a main frame 1, a ventilation device and a thermal insulation device, and the solar cell assembly 2 and the transparent material 7 modules are installed to form a roof. The roof is connected to the main frame 1 by a plurality of components, and the cleaning solar cell assembly 2, the eaves are provided with drainage grooves 4, and the electric energy generated by the solar cells is drawn out through wire slots 8 by electric wires. Inside the solar photovoltaic greenhouse, the positive and negative electrode wires of the solar cell module 2 are converging and drawn out, and are connected to the battery 9 and the control device 10 through the wire slot 8 and the main frame 1 to supply power to the load. The storage battery 9 and the control device 10 have expansion interfaces, and the expansion interfaces are used to connect AC / DC electric equipment.

[0045] The main frame 1 adopts the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com