Thin-film type LED manufacturing method

A thin-film, p-type technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve problems such as unfavorable, short-circuit or leakage of positive and negative electrodes of LEDs, and low heat resistance of silver glue, so as to eliminate light and leakage, Reduce series resistance and ensure the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

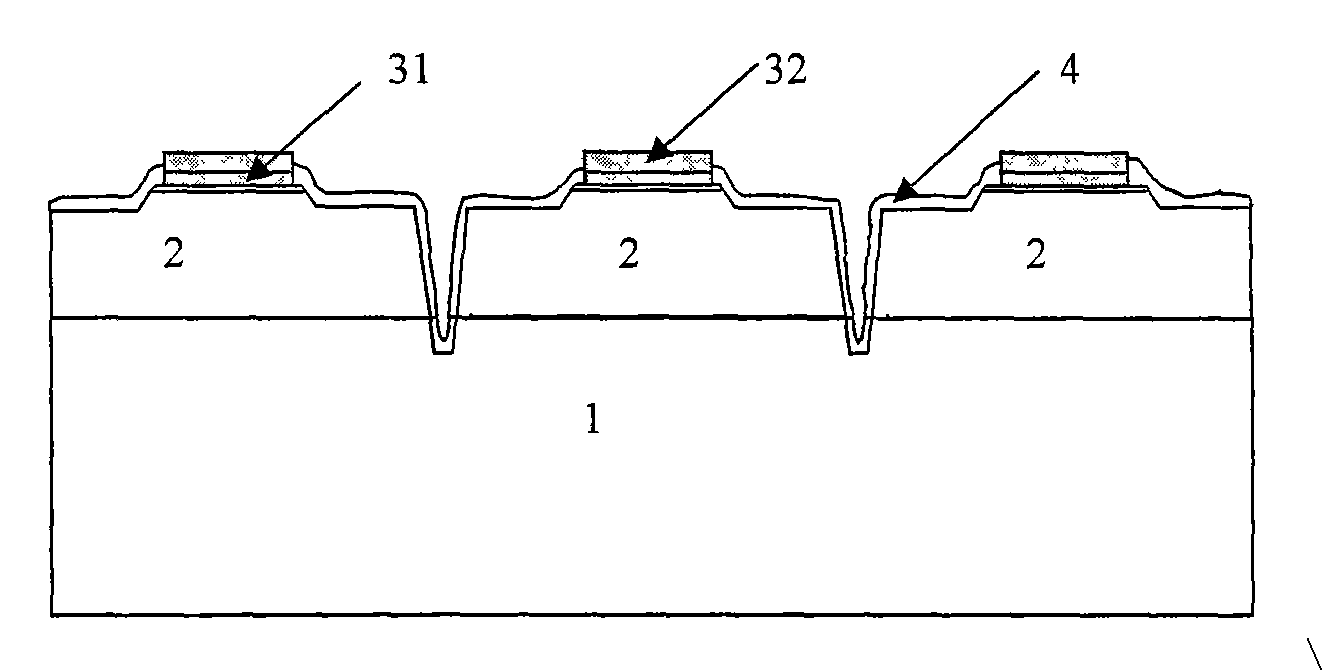

[0051] The preferred embodiment of the present invention will be described in more detail below with reference to the accompanying drawings of the present invention.

[0052] The preparation method of this embodiment comprises the following steps:

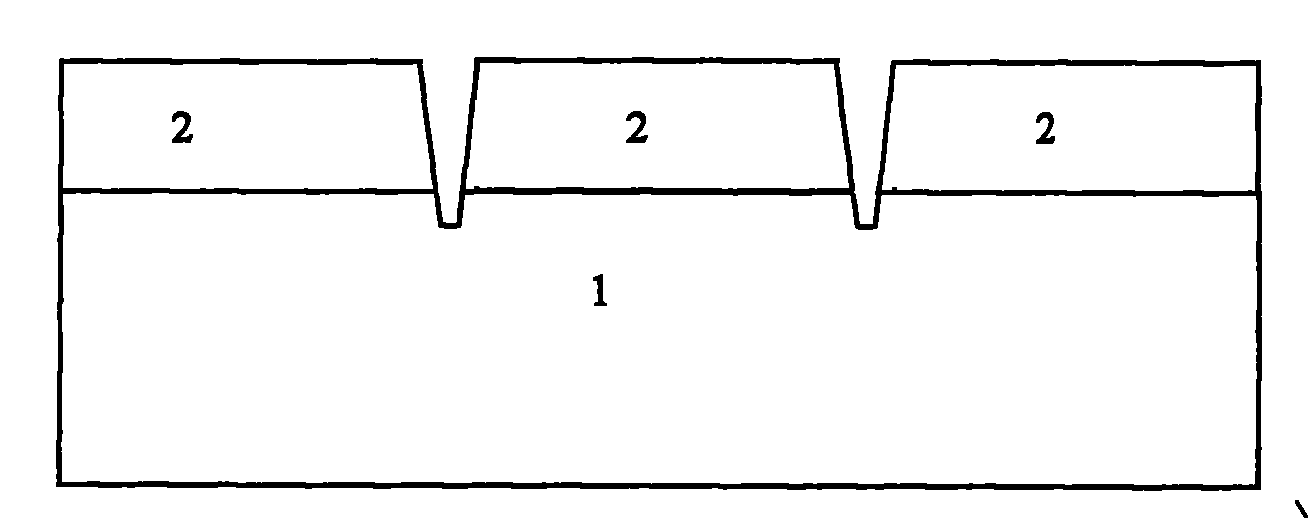

[0053] (1) if figure 1 As shown, a thick GaN-based LED epitaxial layer 2 of an n-type contact layer is grown on a sapphire substrate 1 with a thickness of 350-450 microns, and its thickness is 4-10 microns; The period is the size of the required LED chip, the scribing depth is greater than its thickness, and a certain angle is formed between the side wall of the groove formed by scribing and the substrate 1, and the angle range is 70-85°;

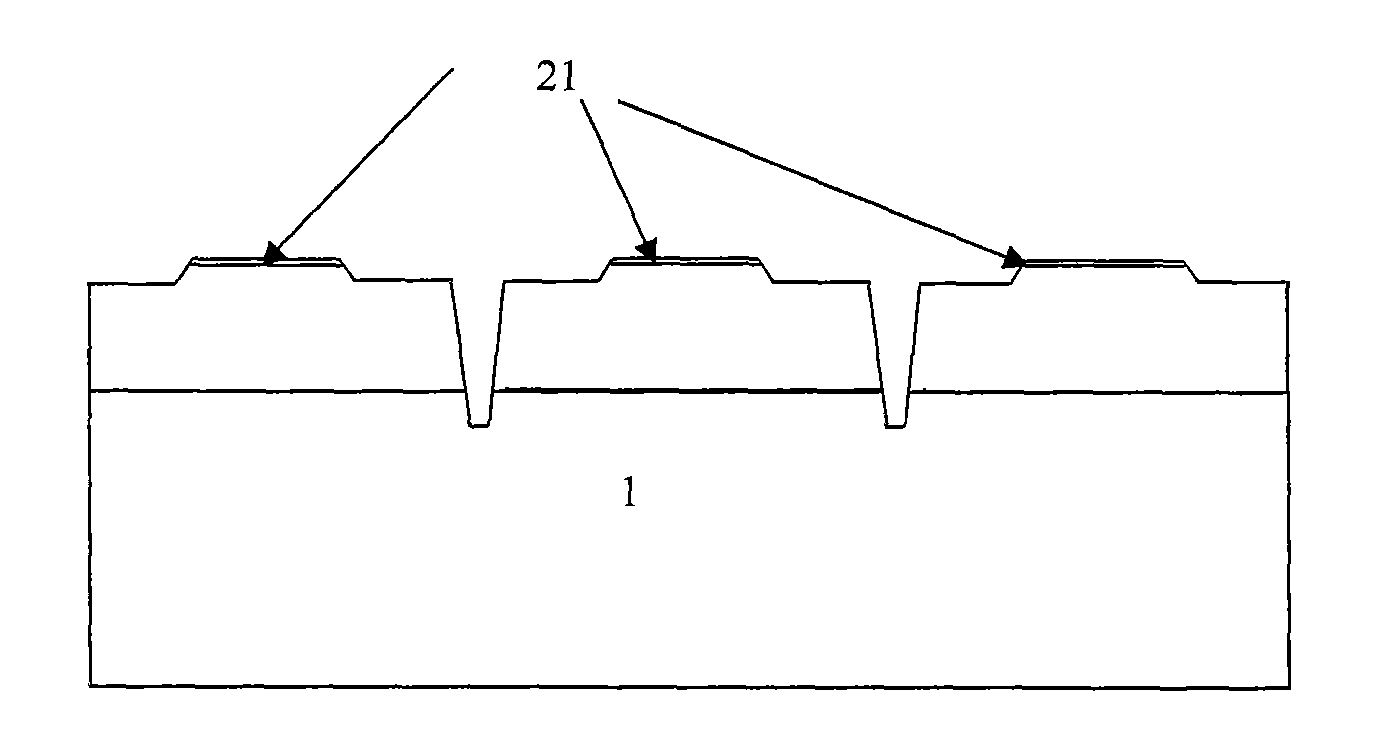

[0054] (2) if figure 2 As shown, reactive ion etching is used to form a trapezoidal mesa 21 on the surface of the epitaxial layer 2. The trapezoidal mesa 21 is located in the middle of the two scribing grooves. The bottom of the mesa reaches the n-GaN layer, and the thickness is between 0.6-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com