Stepper motor drive device based on CAN bus

A CAN bus, stepper motor technology, applied in the field of stepper motor drive devices, can solve the problems of inability to precise displacement, low inherent resolution of stepper motors, limiting the application range of stepper motors, etc., to eliminate resonance points, improve Electrical characteristics, the effect of solving the problem of low frequency oscillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below through specific embodiment and in conjunction with accompanying drawing, this utility model is described in further detail.

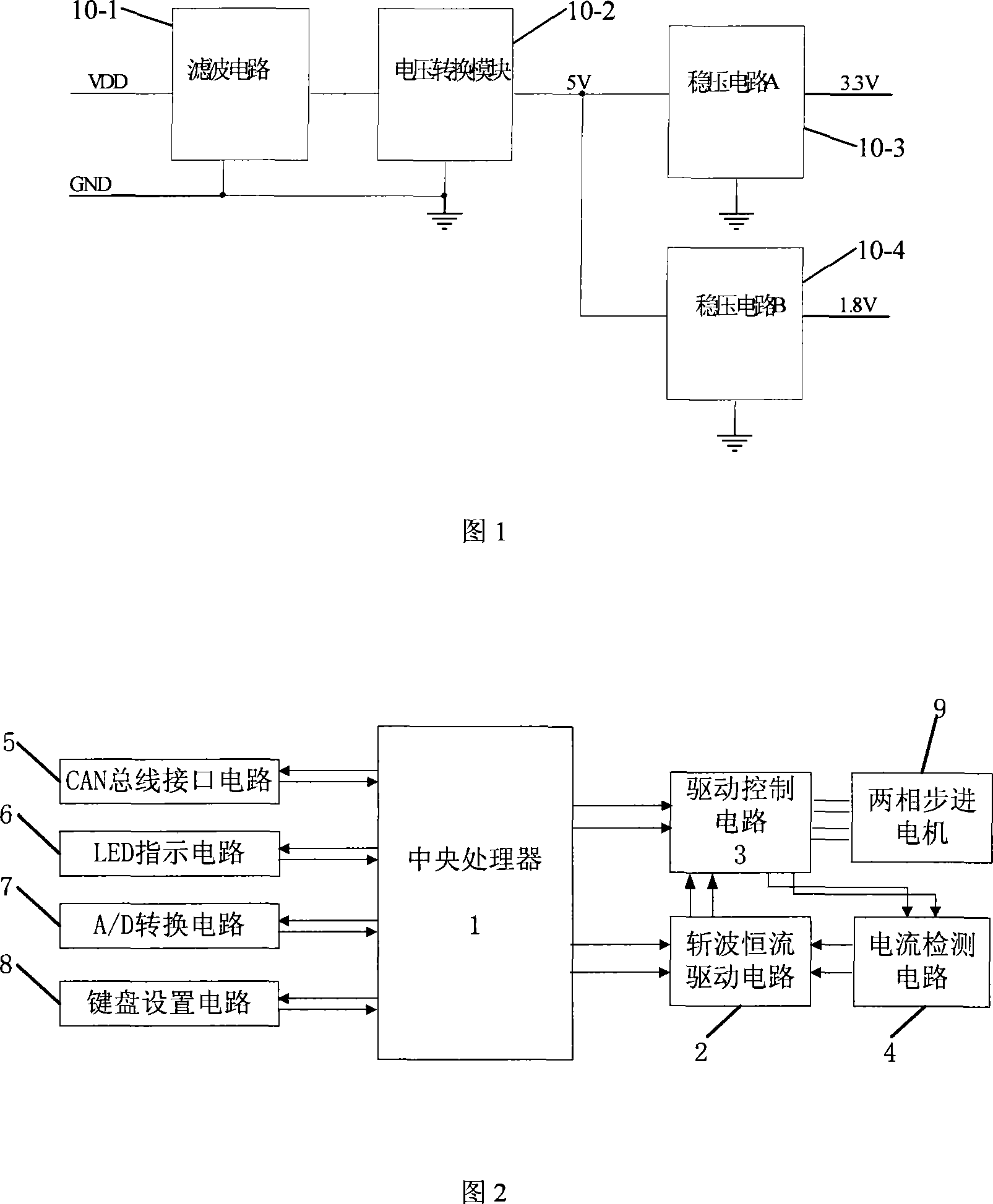

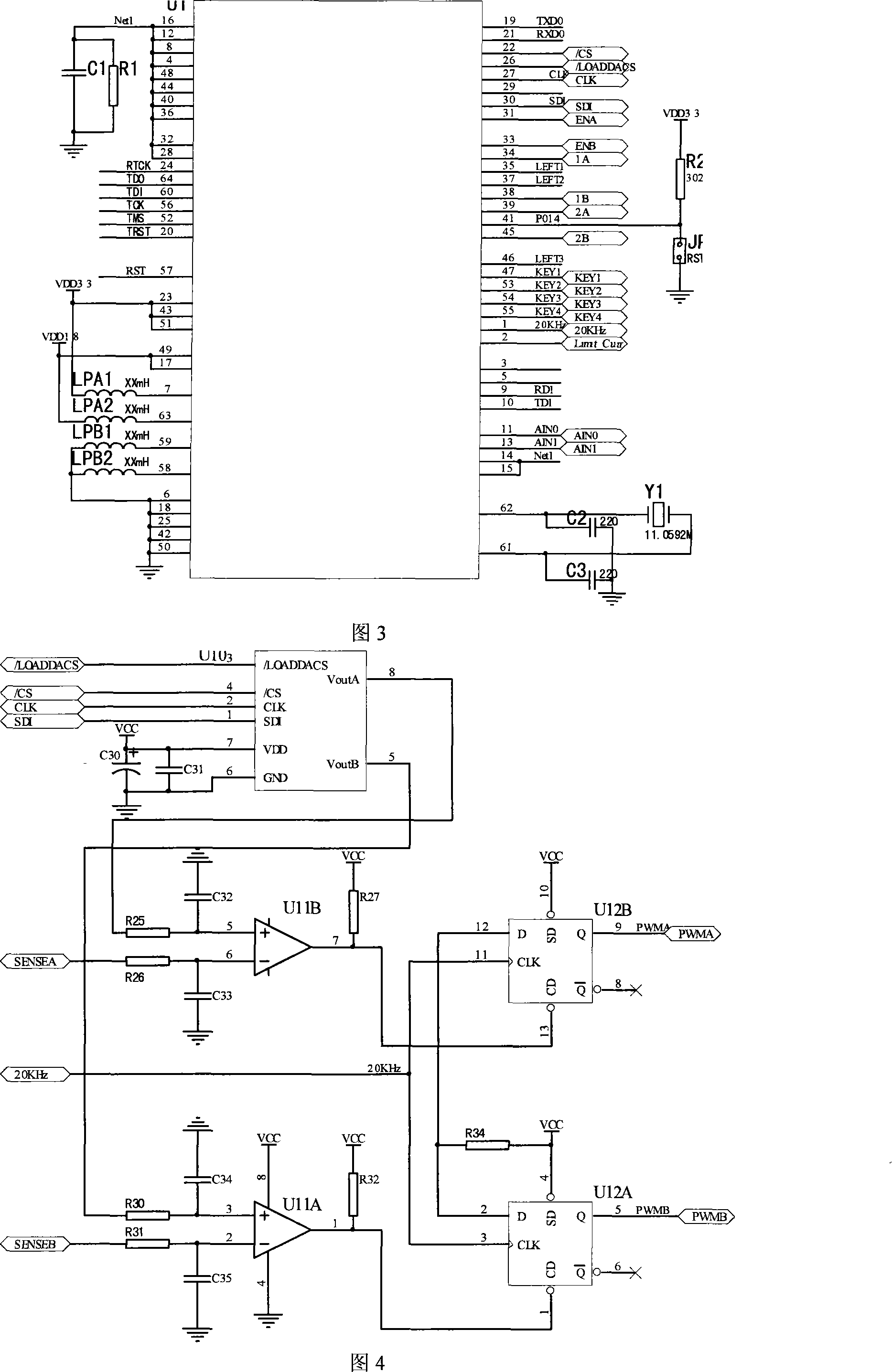

[0032] Such as figure 1 As shown, the power supply part of the CAN bus-based stepper motor drive device includes a filter circuit 10-1, a voltage conversion module 10-2, a voltage stabilizing circuit A 10-3, and a stabilizing circuit B 10-4. The input power is filtered by the filter circuit 10-1 and then input to the voltage conversion module 10-2, and the voltage conversion module outputs a 5V DC voltage for powering the active components of the circuit; the 5V DC voltage passes through the voltage stabilizing circuit A 10 -3 and the voltage stabilizing circuit B 10-4 output voltages of 3.3V and 1.8V to the central processing unit 1 respectively. The input voltage of the voltage conversion module 10-2 can be up to 40V, so that the driving device can be used for stepping motors of different voltage levels. Such as figure 2 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com