Method for preparing series titanium and iron alloy by smelting titanium raw charge

A technology of ferro-titanium alloy and titanium raw materials, which is applied in the field of smelting and preparing series of ferro-titanium alloys from high-phosphorus and sulfur-containing titanium raw materials in Panxi area, which can solve the problems of unreasonable raw material composition, failure to achieve the purpose of the invention, and failure to achieve technical effects, etc. Achieve the effects of stable source, safe and reliable production process, and low level of sulfur and phosphorus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

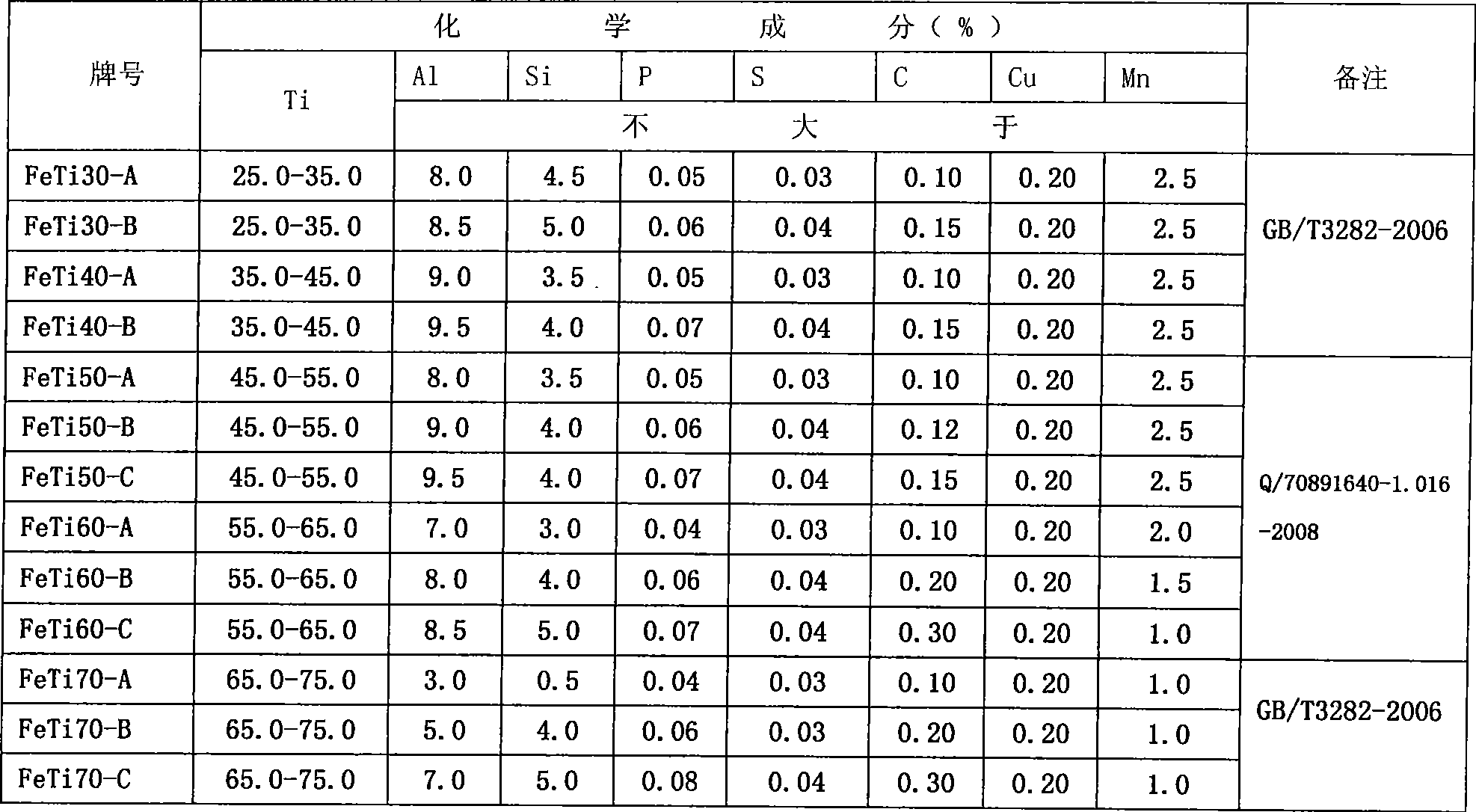

[0044] A kind of preparation method of FeTi30 alloy, it is characterized in that adding the auxiliary material of following weight ratio in 100Kg mainly containing 54% of titanium dioxide, 26.9% of iron-containing titanium raw materials in Panxi area according to the following process steps:

[0045] 42Kg of metal aluminum, 12Kg of quicklime, 8Kg of potassium chlorate, 0.5Kg of dephosphorization and desulfurization agent, 20kg of iron oxide scale with a total iron content of 68%;

[0046] The specific process steps are as follows:

[0047] Based on 100Kg of titanium-containing raw materials, weigh the raw materials and various auxiliary materials according to the above weight ratio, add the titanium raw materials from Panxi area and 4kg of iron-based raw materials into the rotary furnace, and heat them rapidly to 800°C after 20-25min. Then it is sent into the mixer through the connecting bin and mixed evenly, and then quicklime, dephosphorization and desulfurization agent, met...

Embodiment 2

[0052] A kind of preparation method of FeTi40 alloy, it is characterized in that adding the auxiliary material of following weight ratio in 100Kg mainly containing 64% of titanium dioxide, total iron content is 20% titanium raw material of Panxi area according to following process steps:

[0053] 13kg of quicklime, 43Kg of metal aluminum, 9Kg of potassium chlorate, 0.5Kg of dephosphorization and desulfurization agent, 18kg of iron oxide scale with a total iron content of 68%.

[0054] The specific process steps are as follows:

[0055] Based on 100kg of titanium-containing raw materials, weigh the raw materials and various auxiliary materials according to the above weight ratio, add the titanium raw materials from Panxi area and 5.4kg of iron-based raw materials into the rotary furnace, and heat them rapidly to 700°C after 20-25min , and then sent into the mixer through the connecting bin and mixed evenly, and then add quicklime, dephosphorization and desulfurization agent, me...

Embodiment 3

[0060] A kind of preparation method of FeTi50 alloy, it is characterized in that according to following process step, add the auxiliary material of following weight ratio in 100Kg titanium dioxide content is 74%, total iron content is 13% titanium raw material in Panxi area:

[0061] 13kg of quicklime, 45Kg of metal aluminum, 14Kg of potassium chlorate, 0.5Kg of dephosphorization and desulfurization agent, 14kg of iron oxide scale with a total iron content of 68%. The specific process steps are as follows:

[0062] Based on 100kg of titanium-containing raw materials, weigh the raw materials and various auxiliary materials according to the above weight ratio, add the titanium raw materials from Panxi area and 4.2kg of iron-based raw materials into the rotary furnace, and heat them rapidly to 750°C after 20-25min , and then sent into the mixer through the connecting bin and mixed evenly, and then add quicklime, dephosphorization and desulfurization agent, metal aluminum and pota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com