Water-loss reducer for gardening

A water-retaining agent and horticultural technology, which can be applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of low water absorption ratio, easy to produce elongation barriers, rooting barriers, etc. The effect of the number of times to supplement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

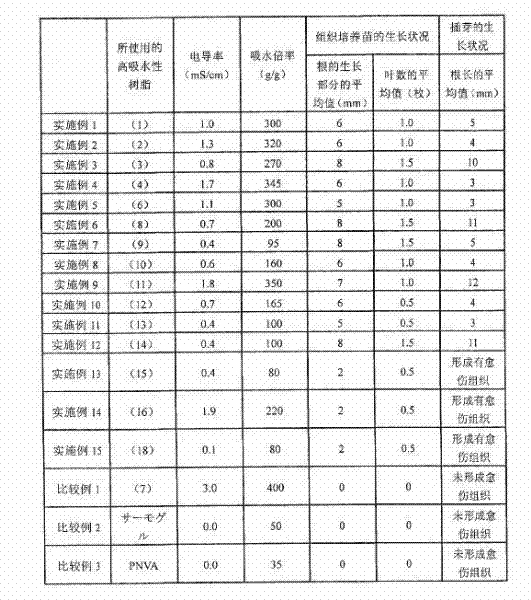

Examples

Embodiment 1

[0104] 230.4 g (3.2 mol) of acrylic acid corresponding to the monomer (C), 1.0 g of pentaerythritol triallyl ether as a crosslinking agent, and 636 g of water were added to a 1 L beaker, and cooled to 10°C. This solution is put into heat-insulated polymerization tank, feeds nitrogen to make the dissolved oxygen of solution be 0.1ppm (utilize Oriente electric company to produce, trade name dissolved oxygen meter DO220PB to measure after), as polymerization initiator, add 35% hydrogen peroxide 0.023g, L-ascorbic acid 0.00575g and potassium persulfate 0.23g. Polymerization started after about 30 minutes and reached a maximum temperature of 72°C after about 2 hours. Furthermore, it was aged at this temperature for 5 hours to complete the polymerization, and the obtained polymer (corresponding to the polymer (Y)) had a hydrogel form. Stir the polymer with a kneader (manufactured by Irie Chamber of Commerce, trade name BENCH KNEADER PNV-1; rotating speed 70rpm) for about 2 hours, c...

Embodiment 2

[0106] Except using the above-mentioned 48% sodium hydroxide aqueous solution 82.7g instead of the 50% calcium hydroxide dispersion liquid 61.6g and 48% sodium hydroxide aqueous solution 64.0g used in Example 1, carry out the same procedure as in Example 1 operation to obtain a superabsorbent resin (2) with an average particle diameter of 500 μm

[0107] (corresponding to polymer (Y)).

Embodiment 3

[0109] Add 43.2 g (0.6 mol) of acrylic acid equivalent to monomer (B), 50.0 g of 48% sodium hydroxide aqueous solution, and 369.2 g (2.6 mol) and water 443.2g, cooled to 5°C. Put the solution into a heat-insulated polymerization tank, feed nitrogen gas to make the dissolved oxygen content of the solution 0.1ppm, then add 0.00016g of 35% hydrogen peroxide, 0.00008g of L-ascorbic acid and 4,4'- Azobis(4-cyanovalerenic acid) 0.04g. After about 30 minutes, the polymerization started, and after about 5 hours, the highest temperature reached about 75° C., and the polymerization was completed to obtain a hydrogel-like polymer (corresponding to the copolymer (X)).

[0110] The gel was stirred with a kneader for 2 hours to be crushed, dried at 120° C. for 1 hour with a belt drier, and crushed to obtain a non-crosslinked dry powder with an average particle diameter of 500 μm. 100 g of this uncrosslinked dry powder with a thickness of 3 mm was put into a stainless steel basin, and heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com