Cold region rice seedling growing multi-potential medium

A technology for rice and cold regions, applied in the field of rice seedling raising all-energy quality and its preparation in cold regions, can solve the problems of complex operation, phytotoxicity, and less root system, increase rice yield, solve the problem of soil extraction, and have a high water storage rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

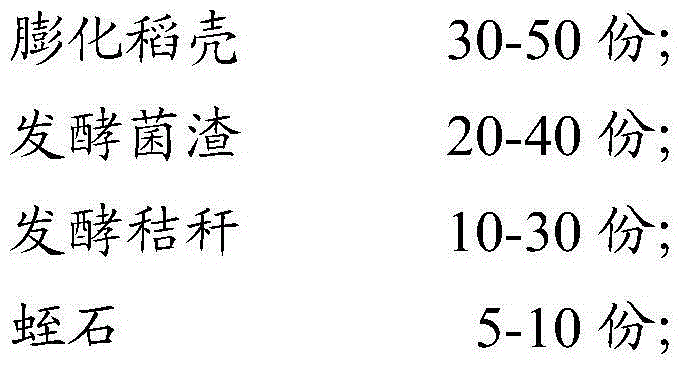

Method used

Image

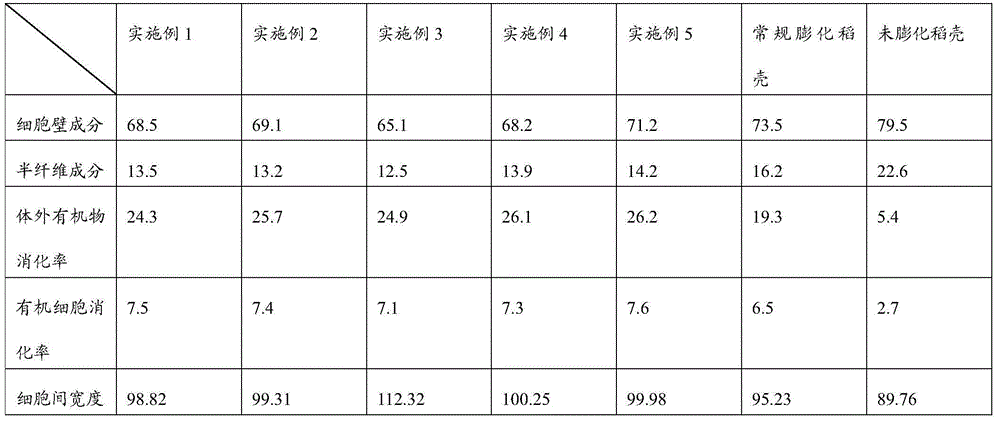

Examples

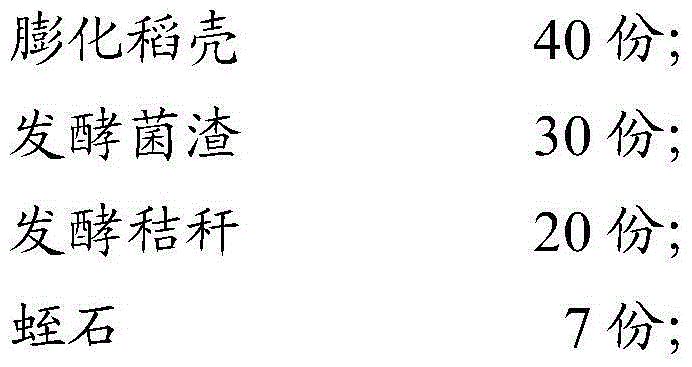

Embodiment 1

[0054] Almighty matrix of the present invention is prepared according to the following steps:

[0055] According to the volume ratio, select 40 parts of full, complete and shiny rice husk, 30 parts of fungus residue, 20 parts of straw and a density of 110kg / m 3, Particle size is 7 parts of expanded vermiculite of 2-4mm, and according to the weight parts of above-mentioned formula, every 100 parts weighs 3 parts of fertilizer, 0.75 part of fungicide and some sulfuric acid stand-by.

[0056] Step a, mix the rice husk and NaOH solution with a concentration of 0.65mol / L according to the ratio of solid to liquid ratio of 1:25, and treat it for 40min at a temperature of 65°C;

[0057] Extruding and puffing the rice husk after the above treatment, wherein the pressure condition is 6-15kg / cm 2 , the temperature condition is 160°C-200°C, and the expanded rice husk is obtained after extrusion and puffing.

[0058] Step b, fully mix the puffed rice husk obtained in step a with the abov...

Embodiment 2

[0064] According to the volume ratio, select 45 parts of full, complete and shiny rice husk, 27 parts of fungus residue, 20 parts of straw and a density of 110kg / m 3 , particle diameter are 5 parts of expanded vermiculites of 2-4mm, and according to the parts by weight of above-mentioned formula, every 100 parts take by weighing 1.5 parts of fertilizers, 1.5 parts of bactericides and some of sulfuric acid stand-by.

[0065] Step a, mix the rice husk and NaOH solution with a concentration of 0.85mol / L according to the ratio of solid to liquid ratio of 1:15, and treat it for 30min at a temperature of 85°C;

[0066] Extruding and puffing the rice husk after the above treatment, wherein the pressure condition is 6-15kg / cm 2 , the temperature condition is 160°C-200°C, and the expanded rice husk is obtained after extrusion and puffing.

[0067] Step b, fully mix the puffed rice husk obtained in step a with the above-mentioned fertilizer and fungicide, and let stand for 2-10 hours. ...

Embodiment 3

[0073] According to the volume ratio, select 50 parts of full, complete and shiny rice husk, 20 parts of fungus residue, 20 parts of straw and a density of 110kg / m 3 , Particle size is 7 parts of expanded vermiculite of 2-4mm, and according to the parts by weight of above-mentioned formula, every 100 parts weighs 2 parts of fertilizer, 1 part of fungicide and some sulfuric acid stand-by.

[0074] Step a, mix the rice husk and NaOH solution with a concentration of 0.75mol / L according to the ratio of solid to liquid ratio of 1:20, and treat for 35min at a temperature of 70°C;

[0075] Extruding and puffing the rice husk after the above treatment, wherein the pressure condition is 6-15kg / cm 2 , the temperature condition is 160°C-200°C, and the expanded rice husk is obtained after extrusion and puffing.

[0076] Step b, fully mix the puffed rice husk obtained in step a with the above-mentioned fertilizer and fungicide, and let stand for 2-10 hours.

[0077] Step c, dry the bacte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com