Compensation mechanism of finish boring hole cylindricity error

A technology of cylindricity error and compensation mechanism, which is applied in the direction of boring/drilling, boring head, drilling/drilling equipment, etc. It can solve problems such as inconsistent dimensions, affecting machine assembly accuracy, and different assembly performance, so as to shorten the length , Increase rigidity, reduce the effect of error re-reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

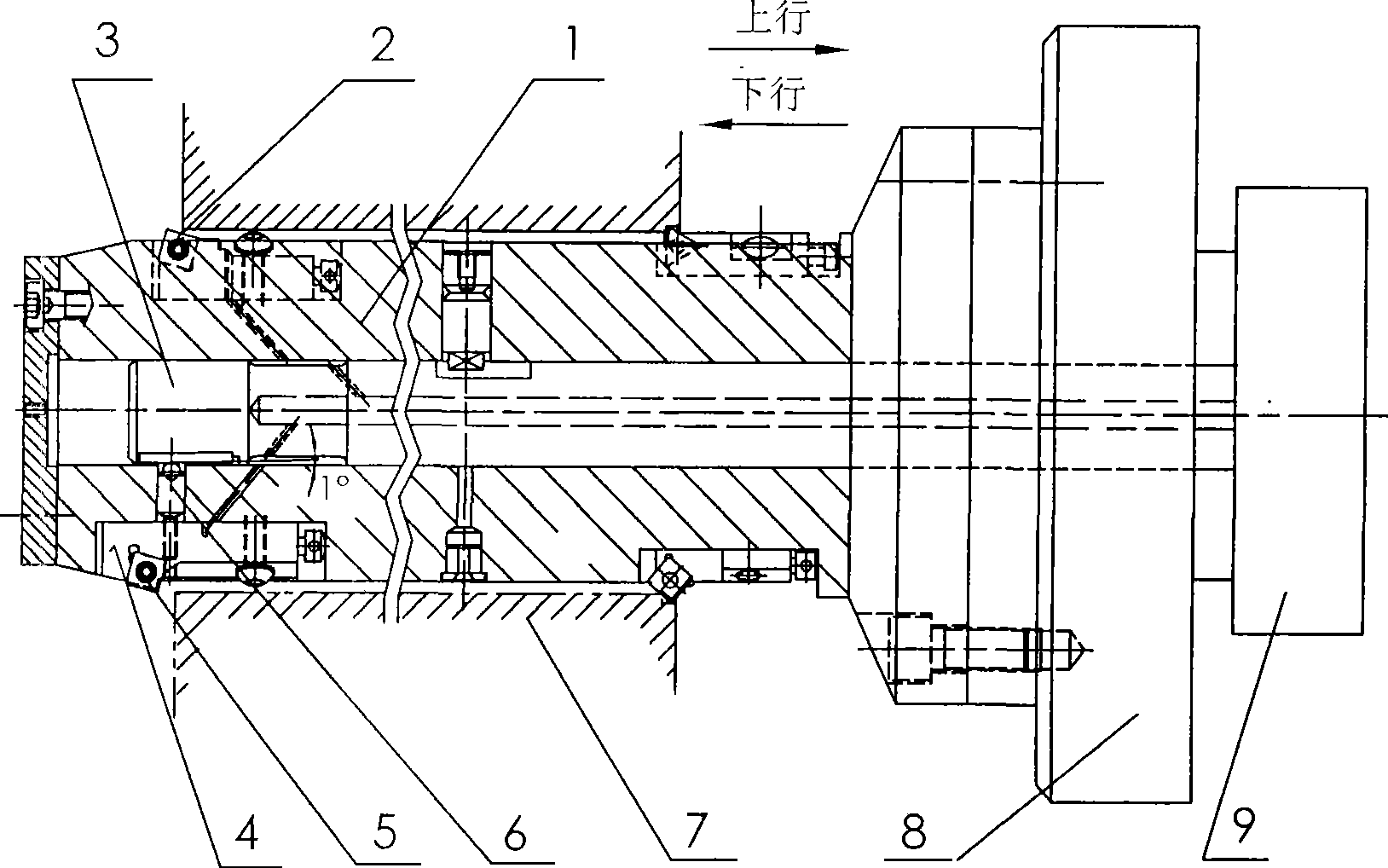

[0008] The figure shows that the push-pull boring bar goes down for semi-finish boring to the final position. In the figure, the front end of the push-pull boring bar (1) is equipped with semi-finish boring inserts (2) and fine boring inserts (5), and the boring bar (1) goes down. When the workpiece (7) can be subjected to fast semi-finish boring processing, when the boring bar (1) semi-finishing goes down to the final position, the tool compensation servo motor (9) starts when the boring bar (1) goes up, through the boring bar ( 1) The 1° slope of the tie rod (3) at the core pushes the ball stud (6) to elastically extend the fine boring tool table (4), and the fine boring tool (5) extends to the working position of the fine boring size to complete the workpiece In the final fine boring process of (7), the power head and the spindle box (8) complete the upward, downward and cutting movements of the push-pull boring tool bar, and the tool compensation servo motor (9) can perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com