Cast-in-place support for long cantilever No. 0 block of cable-stayed bridge with tower beam consolidation and putting up method

A technology of long and cantilevered cable-stayed bridges, applied in bridge construction, bridges, buildings, etc., can solve the problems of low safety factor, difficult construction, high cost, etc., and achieve the effects of clear force, avoiding safety risks, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, process of the present utility model is further described by engineering example.

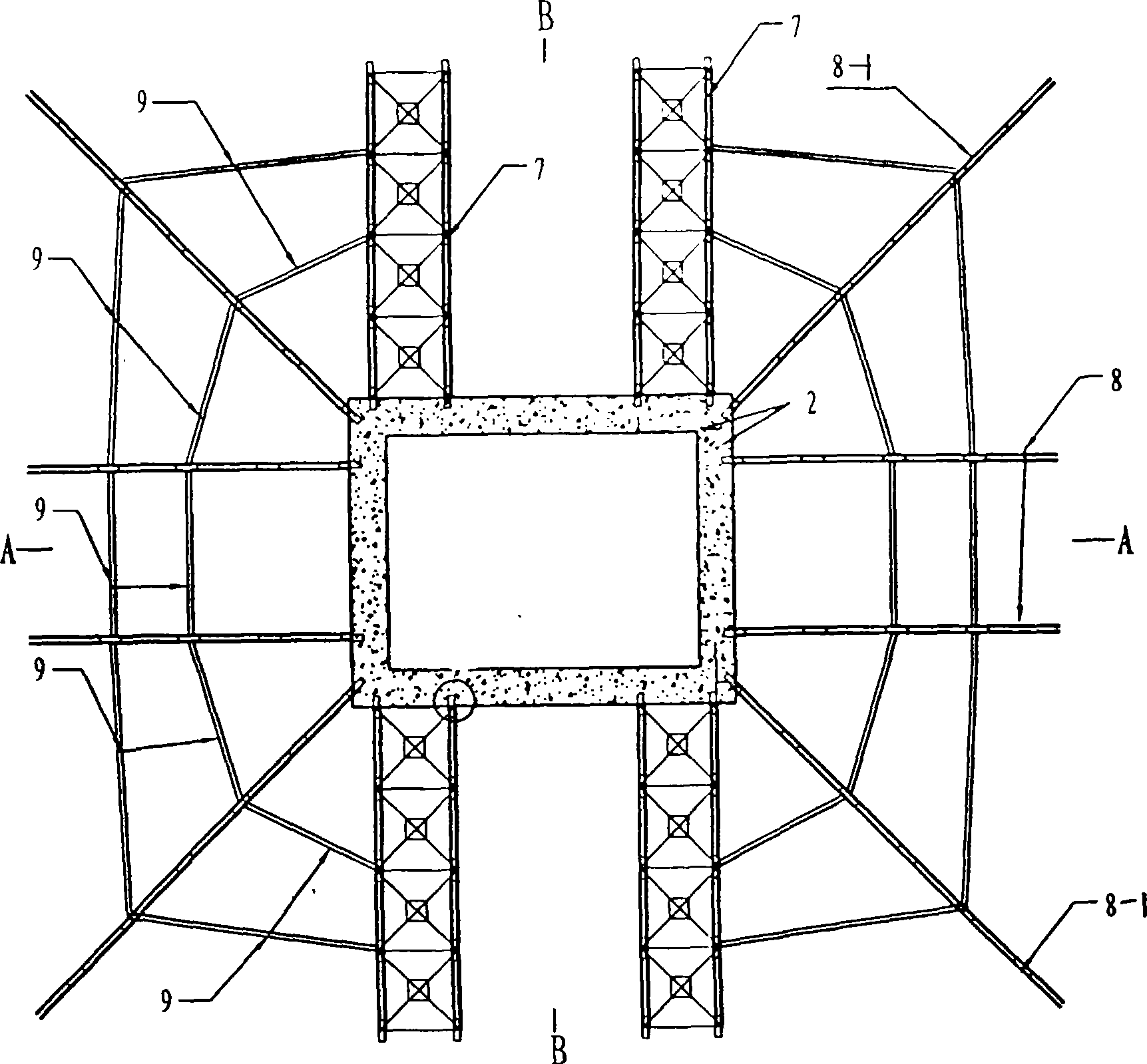

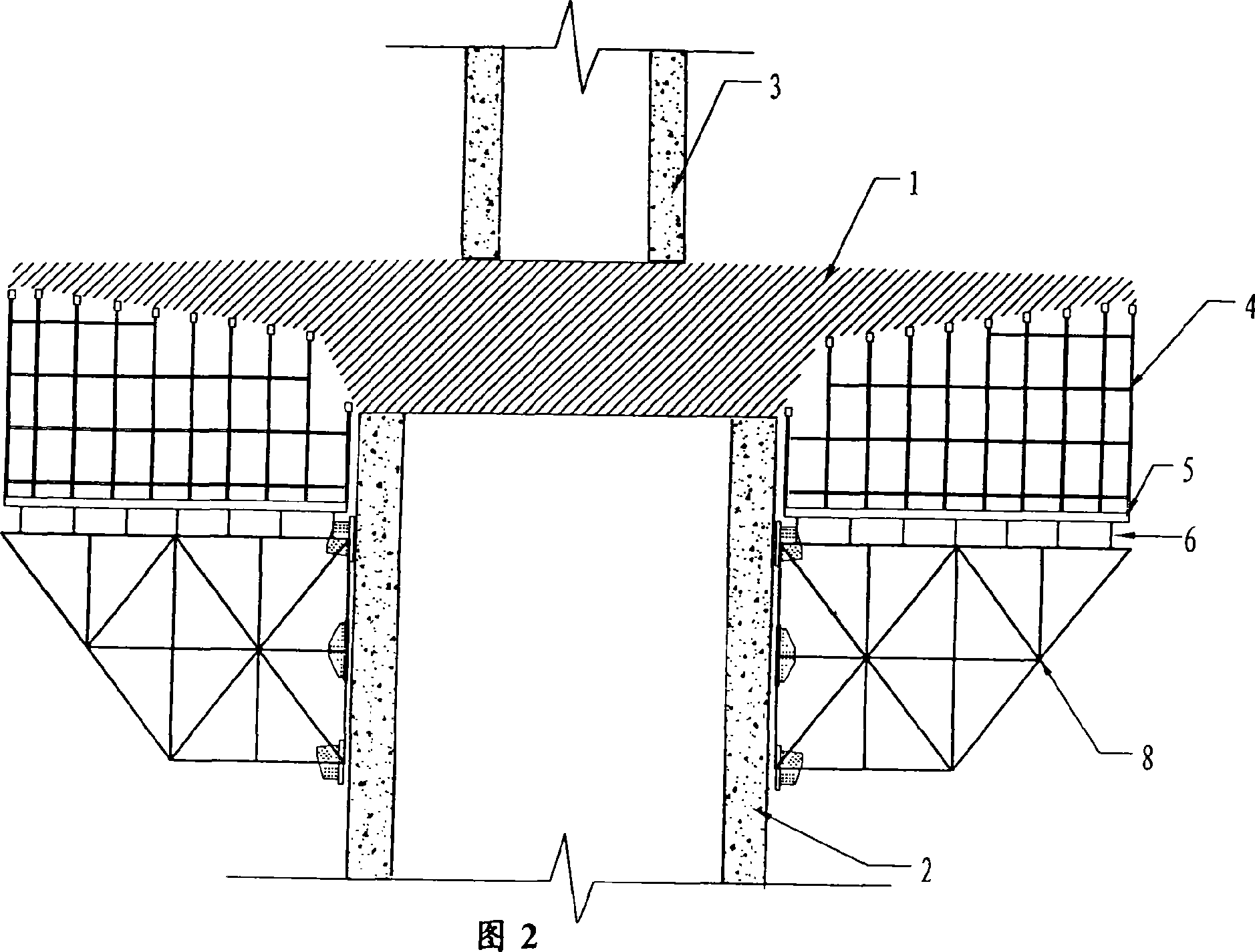

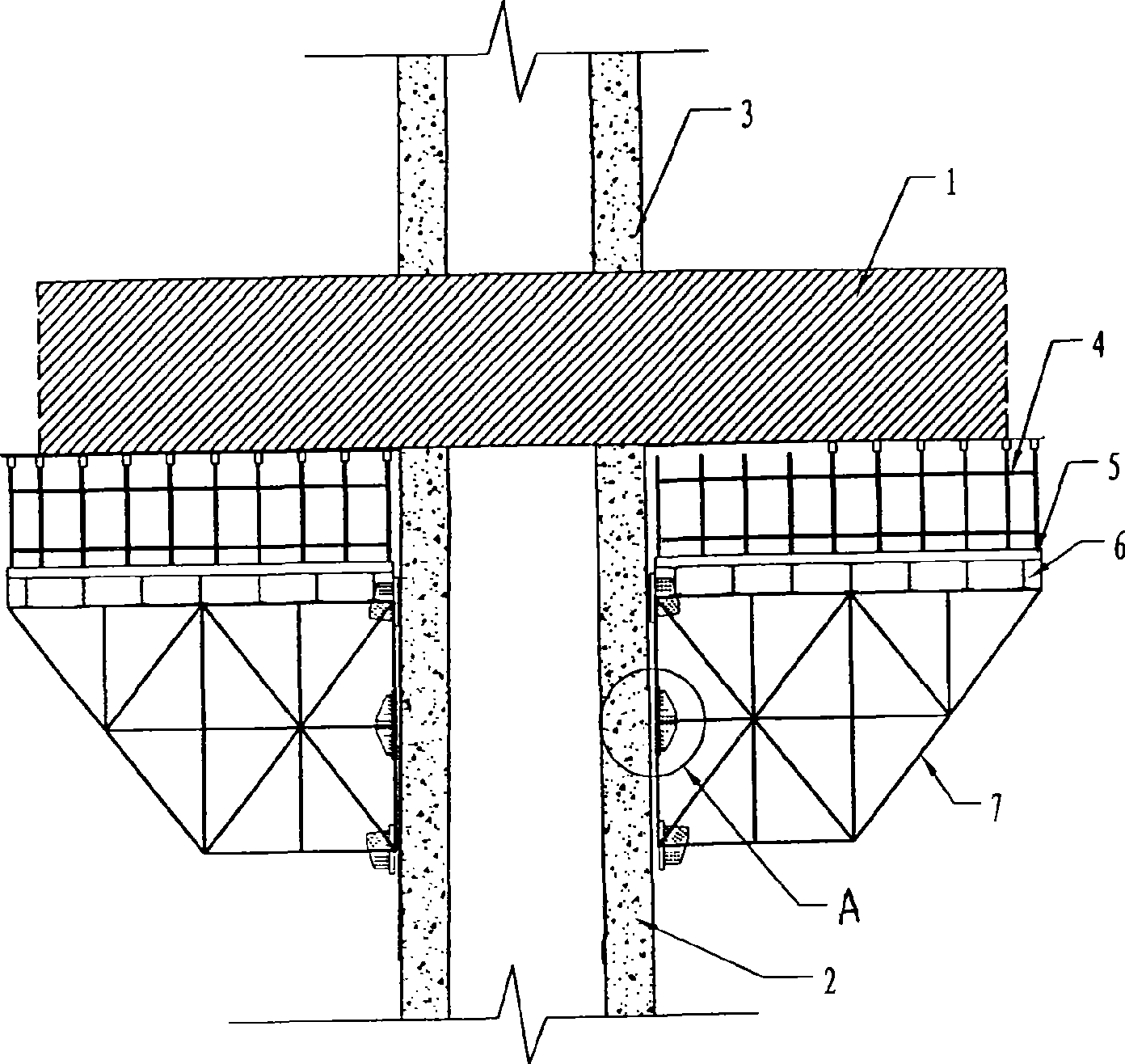

[0029] see figure 1 ,figure 2, image 3 and Figure 4 , a kind of cast-in-situ support of long cantilever 0# block 1 of a tower beam consolidation cable-stayed bridge according to the present invention comprises a detachable truss frame connected to the upper part of the lower tower column 2, and a detachable truss frame laid on the upper part of the lower tower column The I-beam distribution beam 6 above, the sleeper 5 laid on the I-beam distribution beam and the bowl fastener support 4 built on the sleeper;

[0030] The detachable truss frame includes four sets of double truss groups 7 symmetrically connected to both sides of the lower tower column along the direction of the bridge, and four single truss groups symmetrically connected to both sides of the lower tower column along the direction of the bridge. The truss 8 and four obliqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com