Vacuum electron beam melting furnace for polysilicon purification

A vacuum electron beam and smelting furnace technology, applied in the direction of polycrystalline material growth, crystal growth, single crystal growth, etc., to achieve the effects of high energy density, large-scale and automation, and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

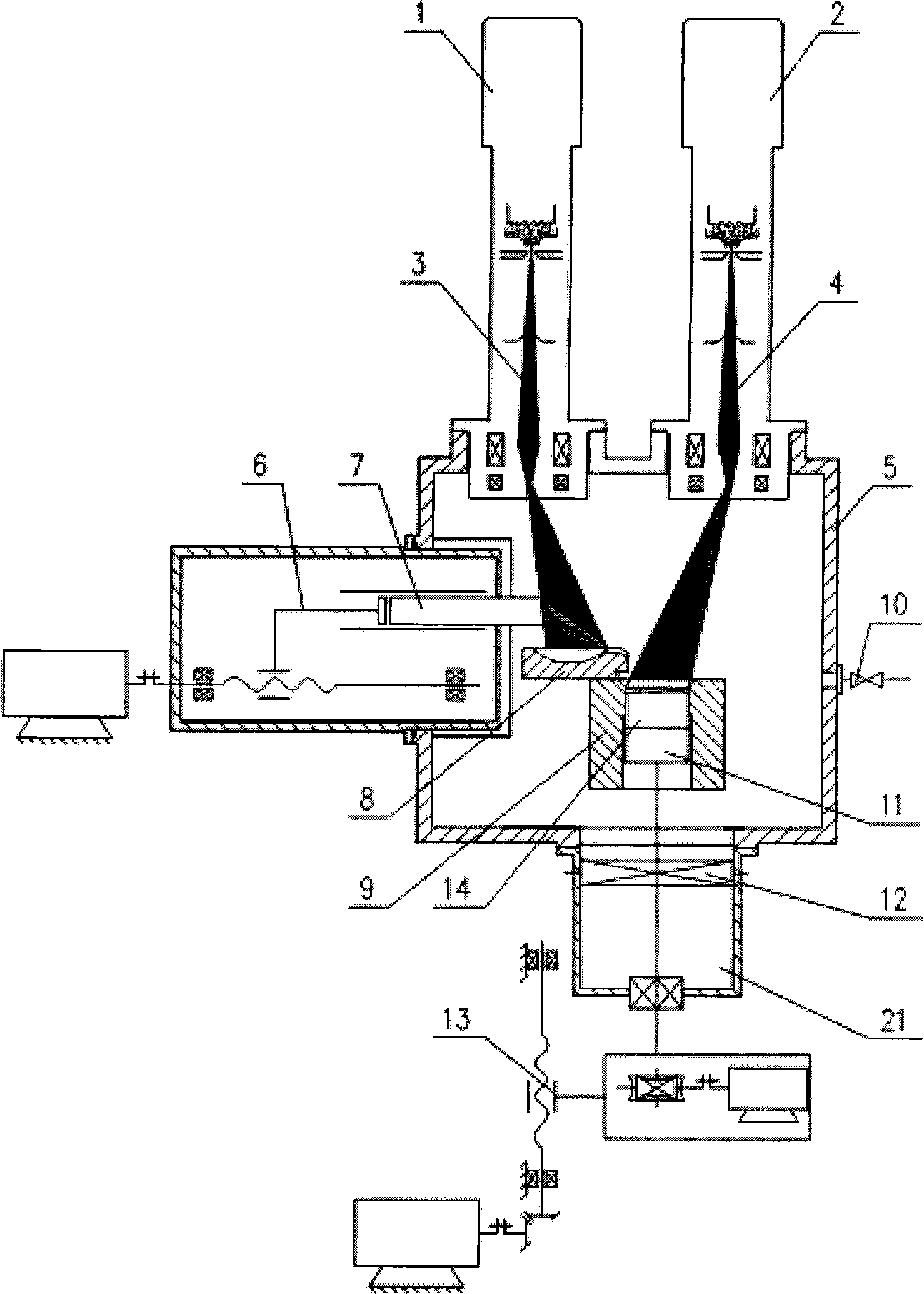

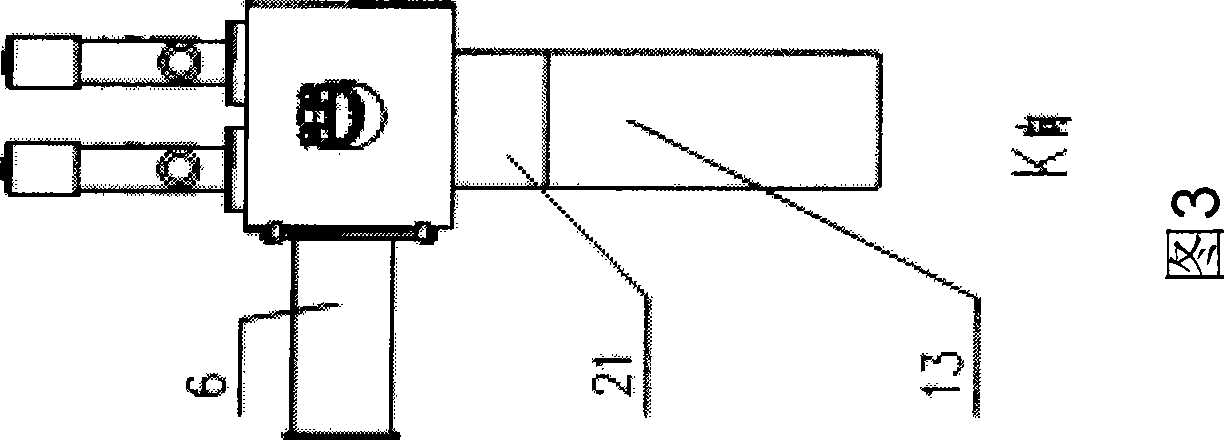

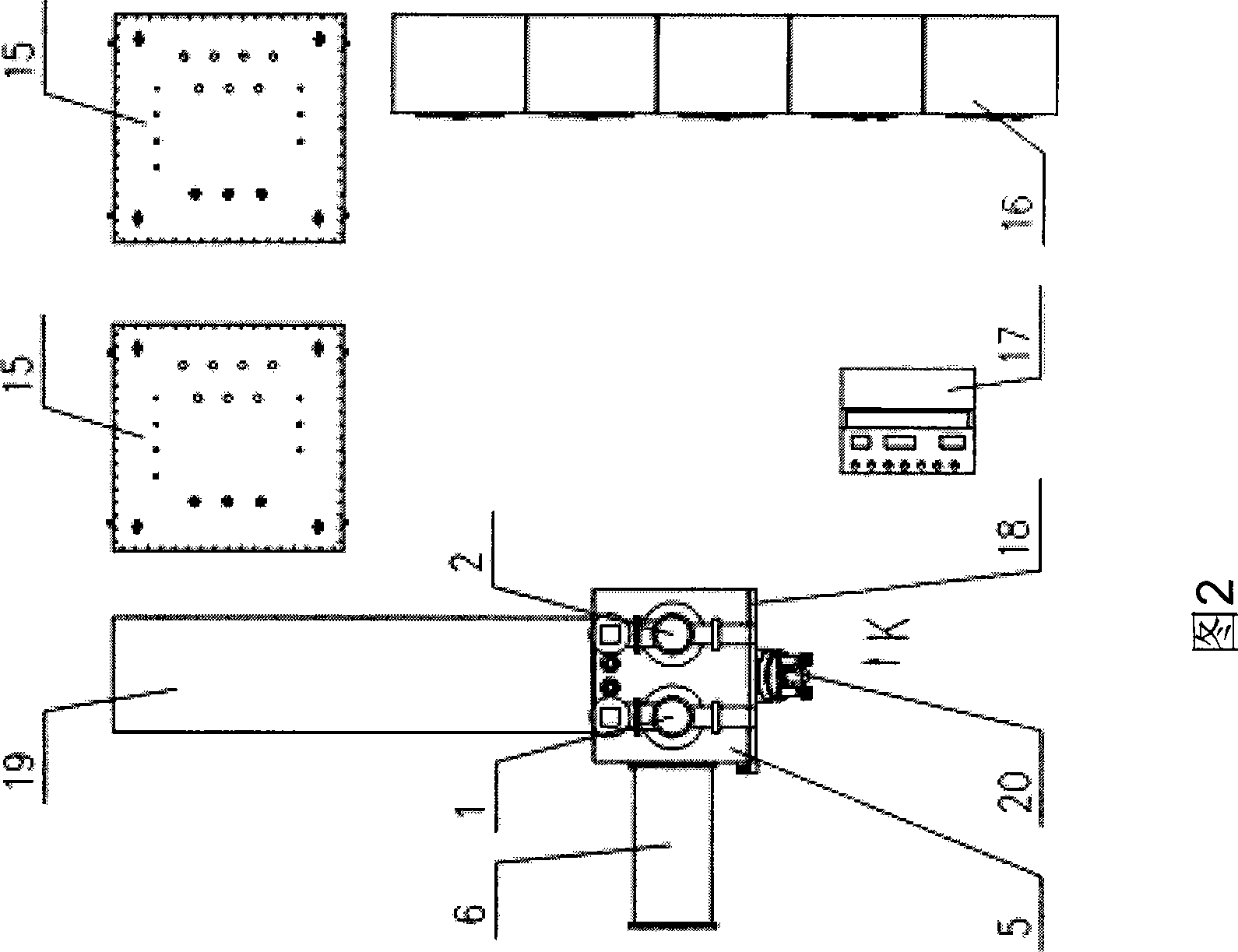

[0029] Reference figure 1 , The vacuum electron beam melting furnace for polysilicon purification of the present invention includes electron gun a1, electron gun b2, electron beam a3, electron beam b4, melting chamber 5, feeding mechanism 6, water-cooled crucible 8, crystallization crucible 9, ingot pulling mechanism 13, and high voltage power supply 15. , Electric control cabinet 16, operation table 17, furnace door 18, vacuum system 19, video observation system 20 and discharge mechanism 21. The melting chamber 5 is square or cylindrical, and the chamber wall is a double-layer water-cooled structure or a coil water-cooled structure. The electron gun a1 and the electron gun b2 are 2-4, which are installed vertically downward on the wall of the melting chamber 5. A vacuum system 19 is arranged above the melting chamber 5, and the feeding mechanism 6 is arranged on one side of the melting chamber 5 and connected to the motor , There is an isolation valve between the feeding chamber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com