Method for preparing carbonyl iron/ PMMA composite magnetic particle basic excitation rheological fluid

A technology of composite magnetic particles and magnetorheological fluid, applied in the direction of lubricating compositions, etc., can solve the problems of poor settlement stability, compaction, easy oxidation and deterioration, etc., and achieve good anti-settling performance and shear stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

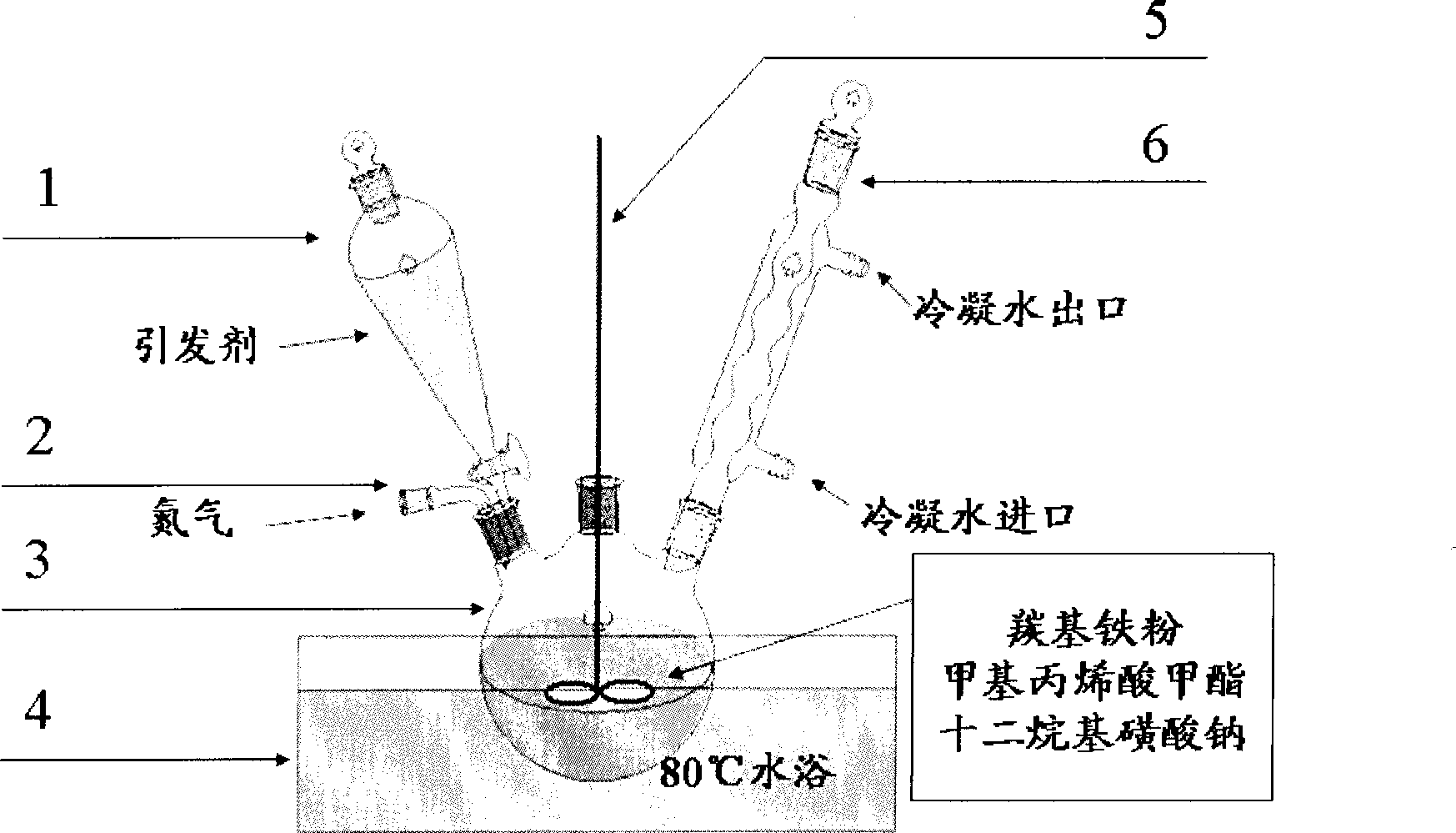

[0035] The experimental apparatus diagram of the present invention is as shown in Figure 1.

[0036] The medicines involved in the preparation method of the present invention include: methyl methacrylate (MethylMethacrylate, MMA, chemically pure), sodium hydroxide (analytical pure), ammonium persulfate (analytical pure), glacial acetic acid (analytical pure), dodecyl Sodium alkyl sulfonate (chemically pure), methyl silicone oil (H201-500), and reagents were purchased from Sinopharm Chemical Reagent Co., Ltd., and were not further processed unless otherwise specified. Carbonyl iron powder (BASF, model: CN).

[0037] The specific preparation method is as follows:

[0038] 1. Nitrogen gas is passed through distilled water for a certain period of time to remove dissolved oxygen;

[0039] 2. Activate a certain amount of carbonyl iron powder with an appropriate amount of glacial acetic acid for several minutes;

[0040] 3. Methyl methacrylate is refined with a certain mass fracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com