Method for processing salted casing

A processing method and casing technology, which is applied in the field of agricultural product processing, can solve the problems that the application of natural casings has not been reported, and achieve the effects of stable natural color, large safety hazards, and low cleaning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

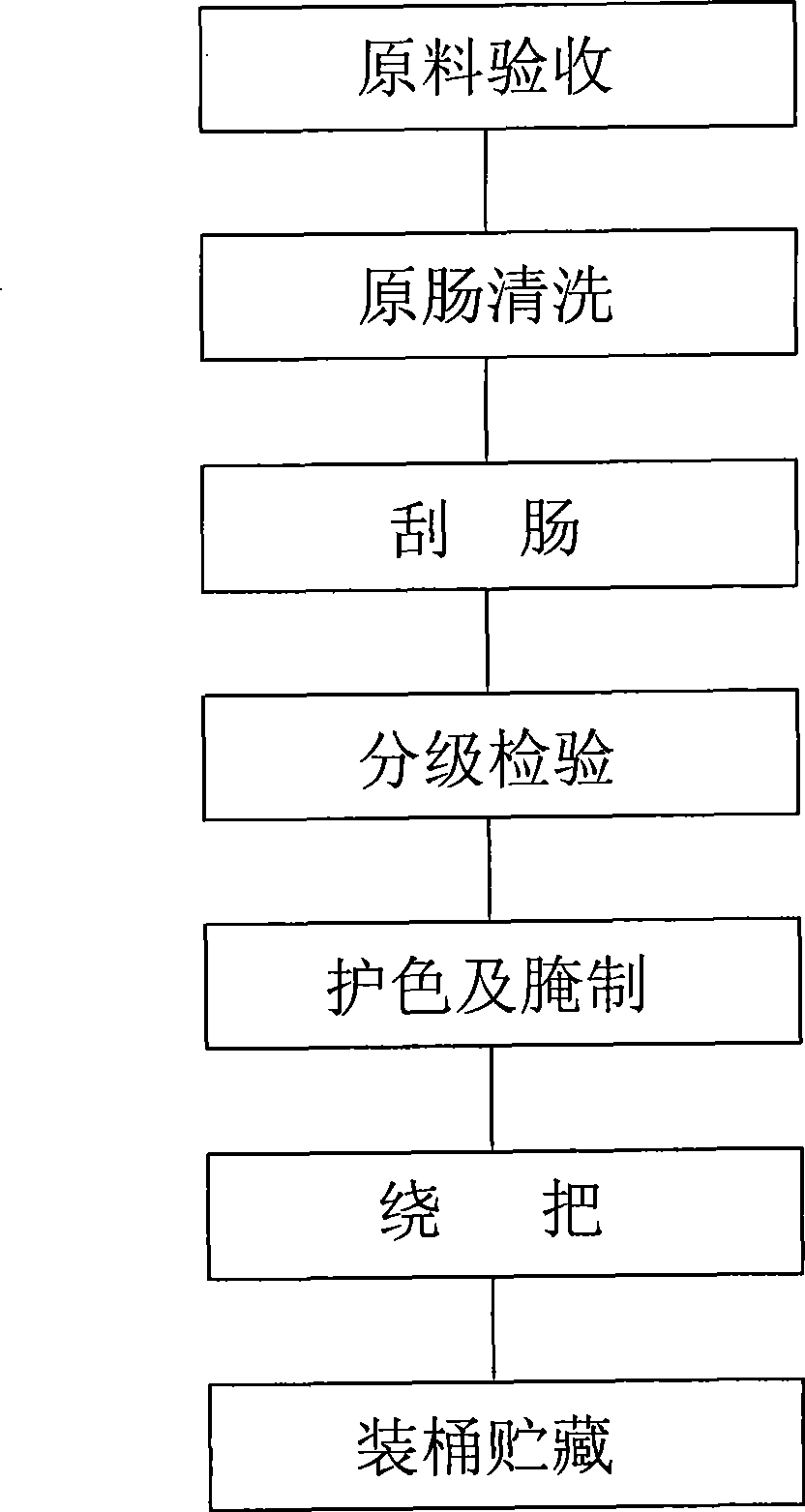

Image

Examples

Embodiment 1

[0018] Embodiment 1: cleaning salted pig casings

[0019] (1) Acceptance of raw materials: The raw materials are required to be fresh, with normal smell and color, no disease spots, and no damage; pig intestines with a length of less than two meters and no use value are removed.

[0020] (2) Ultrasonic cleaning: use a tank-type ultrasonic cleaning machine, put the pig intestines into the tank, set the ultrasonic working frequency to 40kHz, and the temperature to 25°C, and clean for 15 minutes. Turn the raw intestines 1-2 times during the cleaning process. After ultrasonic cleaning, rinse with clean water, comb neatly and prepare for machine scraping.

[0021] (3) Intestine scraping: Machine scraping is used. Check the gap between the knife edge and the rubber roller before starting the machine, and adjust the gap to be consistent throughout the length of the knife edge. Turn on the machine and run idling for 2 minutes, then feed the pig intestines into the knife edge, pull o...

Embodiment 2

[0027] Example 2: Cleaning salted goat casings

[0028] (1) Acceptance of raw materials: The raw materials are required to be fresh, with normal smell and color, no disease spots, and no bruises; the sheep intestines with a length of less than two meters and worthless sheep intestines should be removed.

[0029] (2) Ultrasonic cleaning: using a tank-type ultrasonic cleaning machine, put the goat intestines into the tank, set the ultrasonic working frequency to 40kHz, and the temperature to 25°C, and wash for 15 minutes. Turn the raw intestines 1-2 times during the cleaning process. After ultrasonic cleaning, rinse with clean water, comb neatly and scrape intestines.

[0030] (3) Intestine scraping: Use a rubber scraper to scrape the intestines manually. When scraping the intestines, straighten the original intestines, pour 30-40 cm of water from the junction of the cecum, and then flatten the intestines, and scrape them with the back of the knife tilted to the other end . B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com