Discharge lamp, electrode, and method of manufacturing an electrode portion of a discharge lamp

A technology for electrode parts and discharge lamps, which is applied in the parts of gas discharge lamps, the manufacture of discharge tubes/lamps, and discharge lamps, etc., can solve the problems of long sintering time, difficulty in sintering electrodes and porous electrodes, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

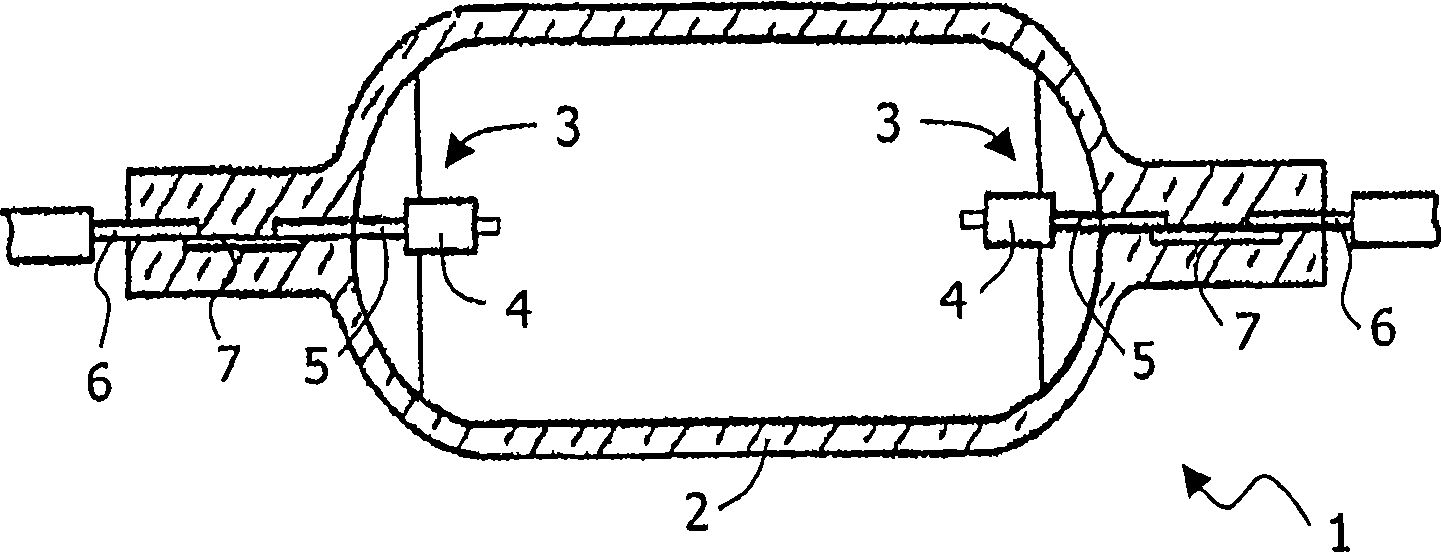

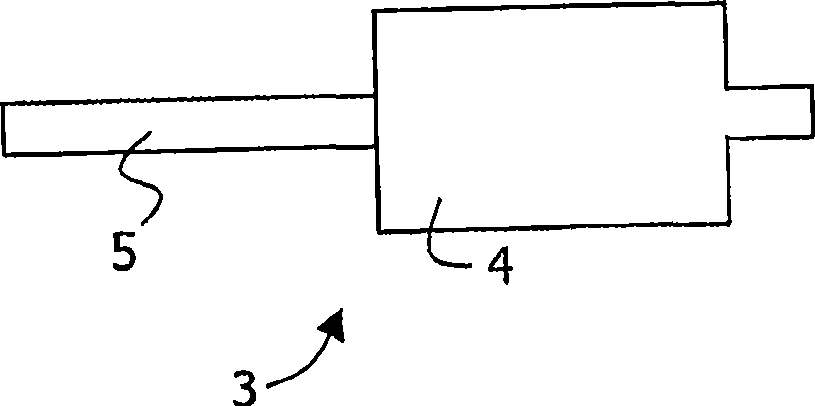

[0022] figure 1 An AC high pressure gas discharge (HID) lamp 1 is shown, hereinafter referred to as lamp 1 . The lamp 1 has a sealed transparent or translucent bulb 2 forming a discharge chamber housing electrodes 3 each having a porous electrode part 4 and an elongated part 5, ie the electrodes 3 have well-defined electrode tips. Current can be fed to or from the electrode 3 via the lead wire 6 and the feed conductor 7 . figure 2 A detailed image of the electrode 3 is shown, where the porous electrode part 4 is a reshaped extruded cylindrical part and the elongated part 5 is a drawn rod.

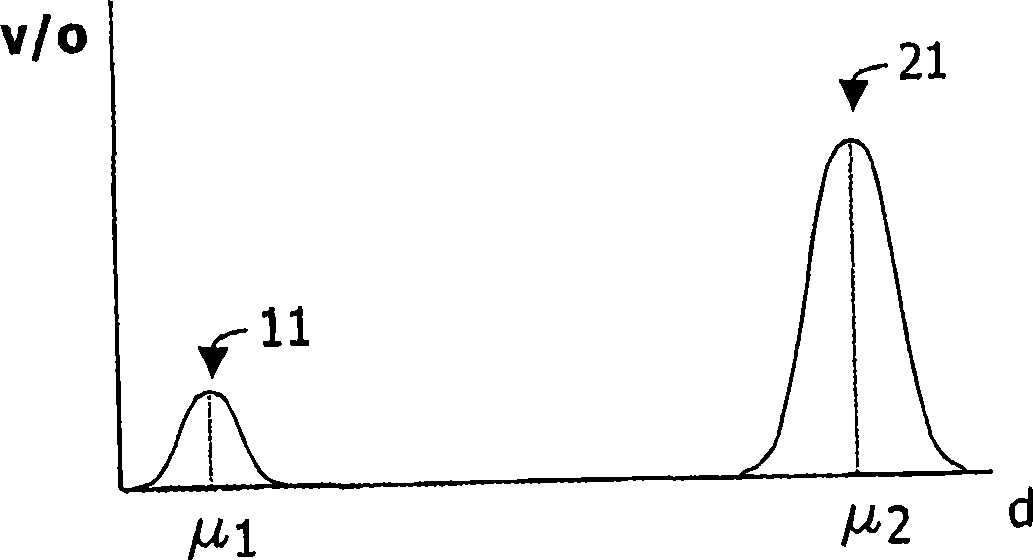

[0023] image 3 A schematic particle size diagram of the material mixture used to obtain the porous electrode portion 4 according to the embodiment of the present invention is shown. The vertical axis represents the volume percentage of the powder, and the horizontal axis represents the particle size d. FIG. 4 shows a scanning electrode micrograph of part 4 after sintering.

[0024] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com