Flat non down-lead encapsulation piece and method for producing the same

A flat leadless, production method technology, applied in electrical components, electrical solid-state devices, semiconductor devices, etc., can solve problems such as product delamination defects, performance degradation, and customer use troubles, and achieve significant anti-delamination defects and structural Simple and reasonable, the effect of improving packaging yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] 1. Wafer thinning / scribing

[0071] The thinning of the wafer packaged with a thickness of 0.75mm is the same as that of ordinary QFN plastic-encapsulated integrated circuits. First paste the adhesive film on the front of the wafer, and then thin it on a special thinning machine. The thickness of the wafer thinned is controlled at 180 μm.

[0072] 2. Core loading

[0073] The upper core adopts the following special frame:

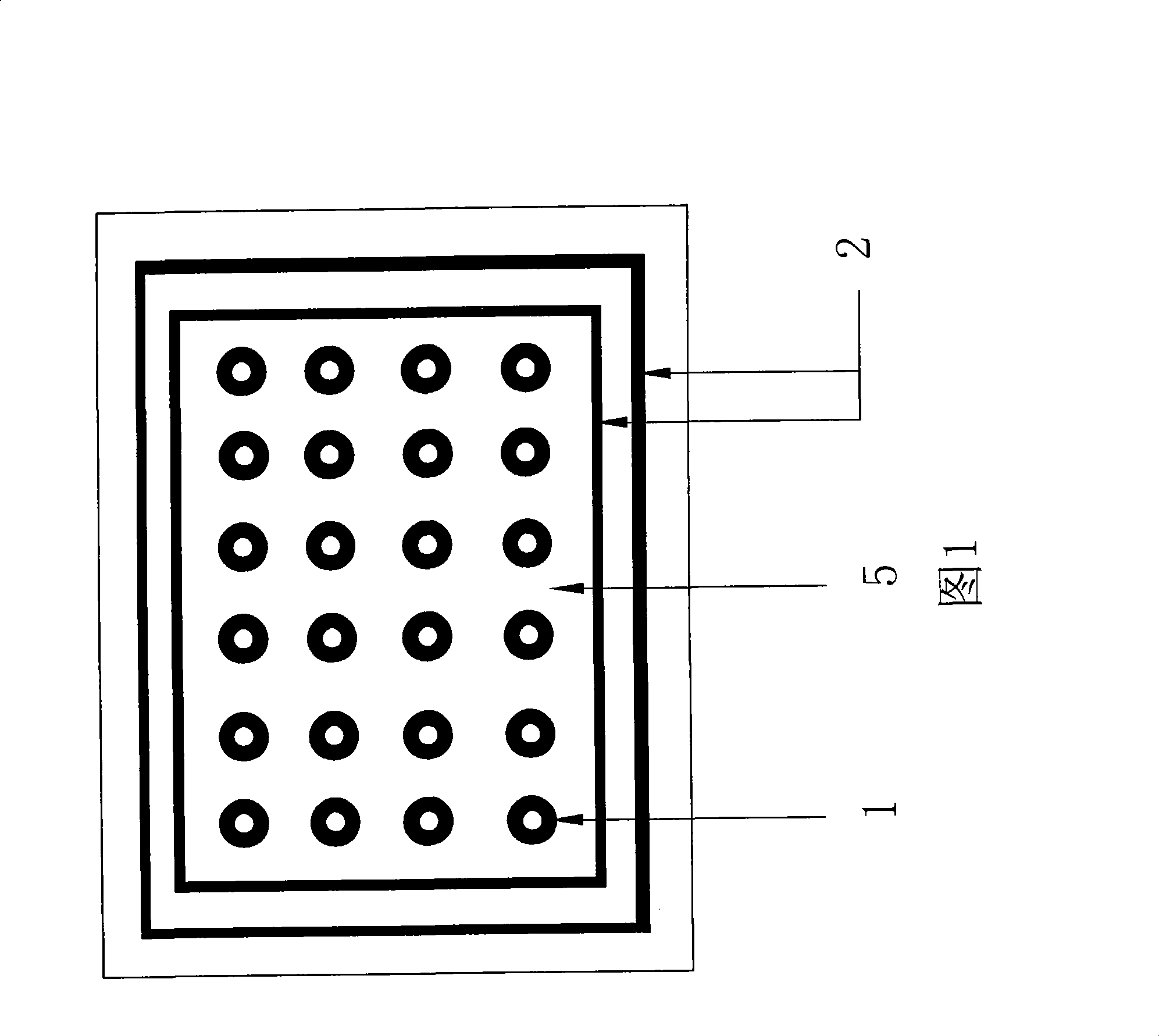

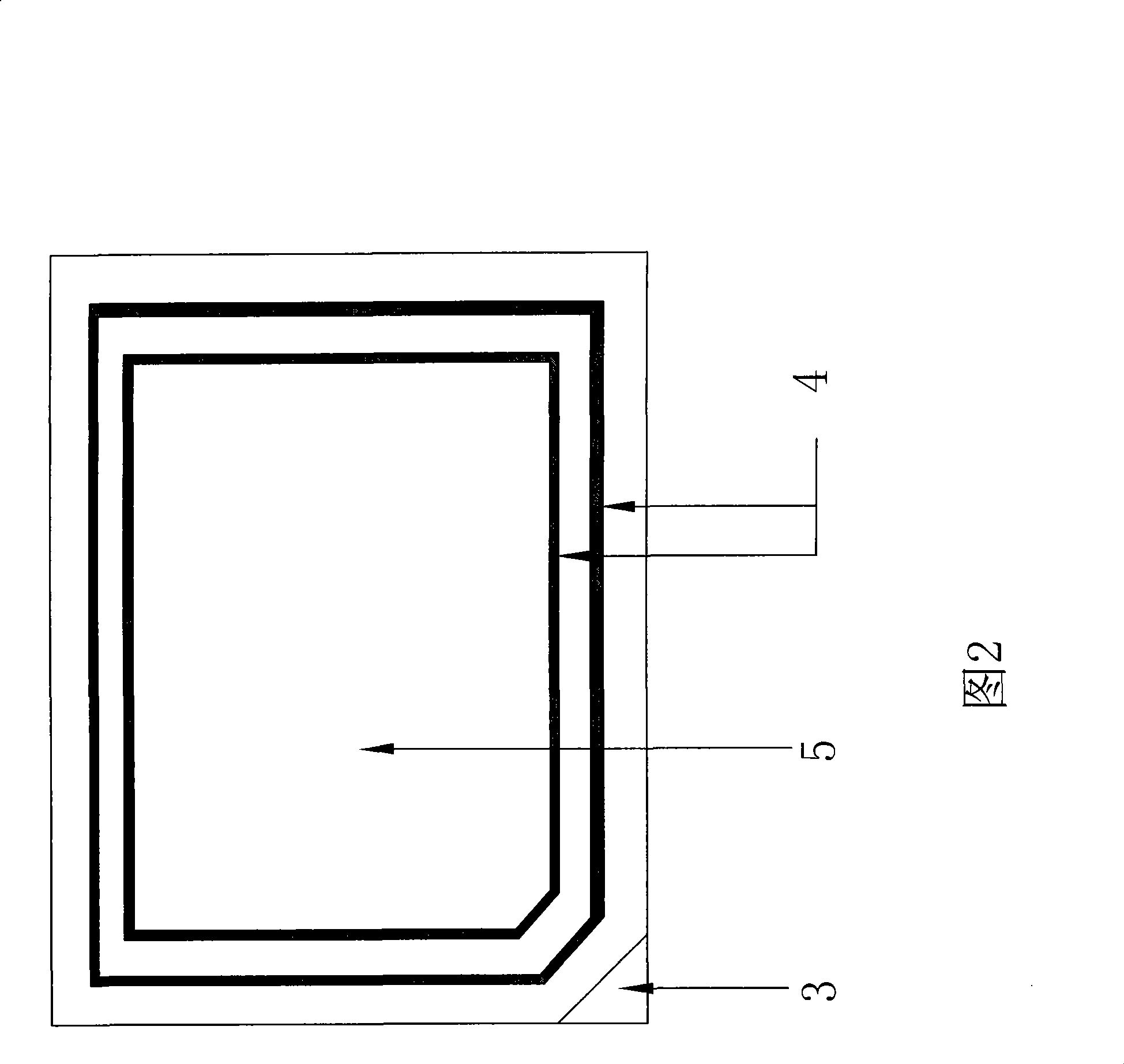

[0074] There are multiple rows of circular or trapezoidal pits 1 on the front of the lead frame carrier 5, and there are two circles of waterproof grooves 2 on the edge of the lead frame carrier; there is a 45-degree bevel at the lower right corner of the back of the carrier, as a PIN1 mark, and there are two circles on the edge of the carrier. Ring anti-overflow groove 4. At the same time, the back of the lead frame is pasted with an ordinary adhesive film when it leaves the factory.

[0075] The conductive adhesive, that is, the insulating adhe...

Embodiment 2

[0088] 1. Wafer thinning / scribing

[0089] For wafers packaged with a thickness of 0.5mm, the chip thickness is controlled between 130μm and 150μm. Anti-fragmentation and anti-warping thinning process control technology is adopted. Coarse grinding is used within the range of incoming wafer thickness + adhesive film thickness - 50μm thickness. Grinding speed ≤ 30μm / min; use fine grinding within the range of final wafer thickness + adhesive film thickness + 30μm, and fine grinding speed ≤ 10μm / min. In scribing, the scribing feed speed is ≤10mm / s, and a double-knife scribing machine is used if necessary.

[0090] 2. Core loading

[0091] The upper core adopts the following special frame:

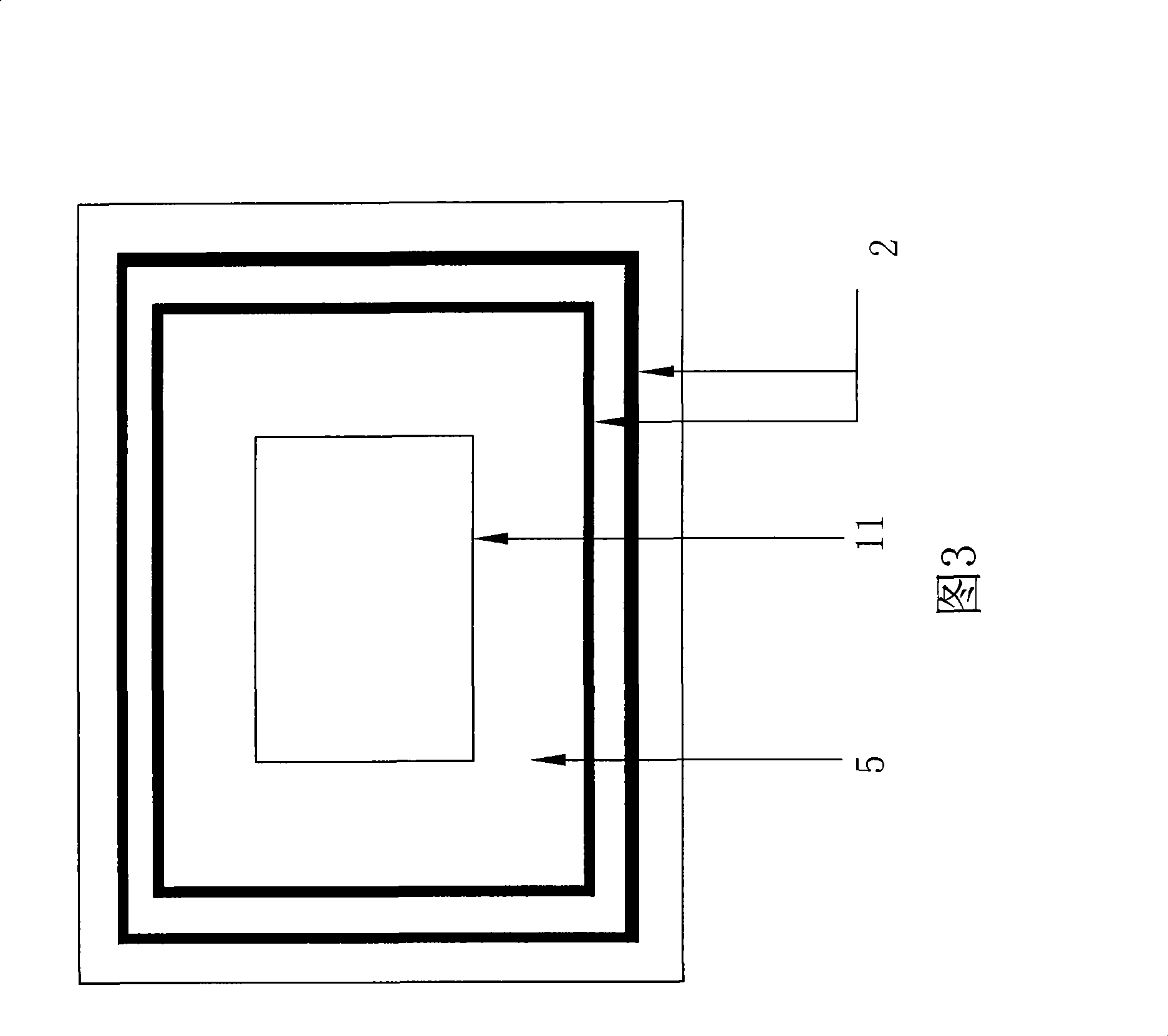

[0092] There is a rectangular or square pit 1 on the front of the lead frame carrier 5 , and the bottom surface of the pit 1 is flat. There are two circles of waterproof grooves 2 on the edge of the lead frame carrier. The lower right corner of the back of the lead frame carrier 5 is design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com