Liquid suction core support component and manufacturing method thereof and integrated hot pipe

A support member and liquid-absorbing core technology, which is applied in the field of heat transfer, mass transfer and heat dissipation, can solve the problems of blocked liquid-absorbing channels, easy to dry up, small gaps, etc., to increase liquid return flow, improve heat transfer effect, and improve porosity Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below through specific embodiments and in conjunction with the accompanying drawings.

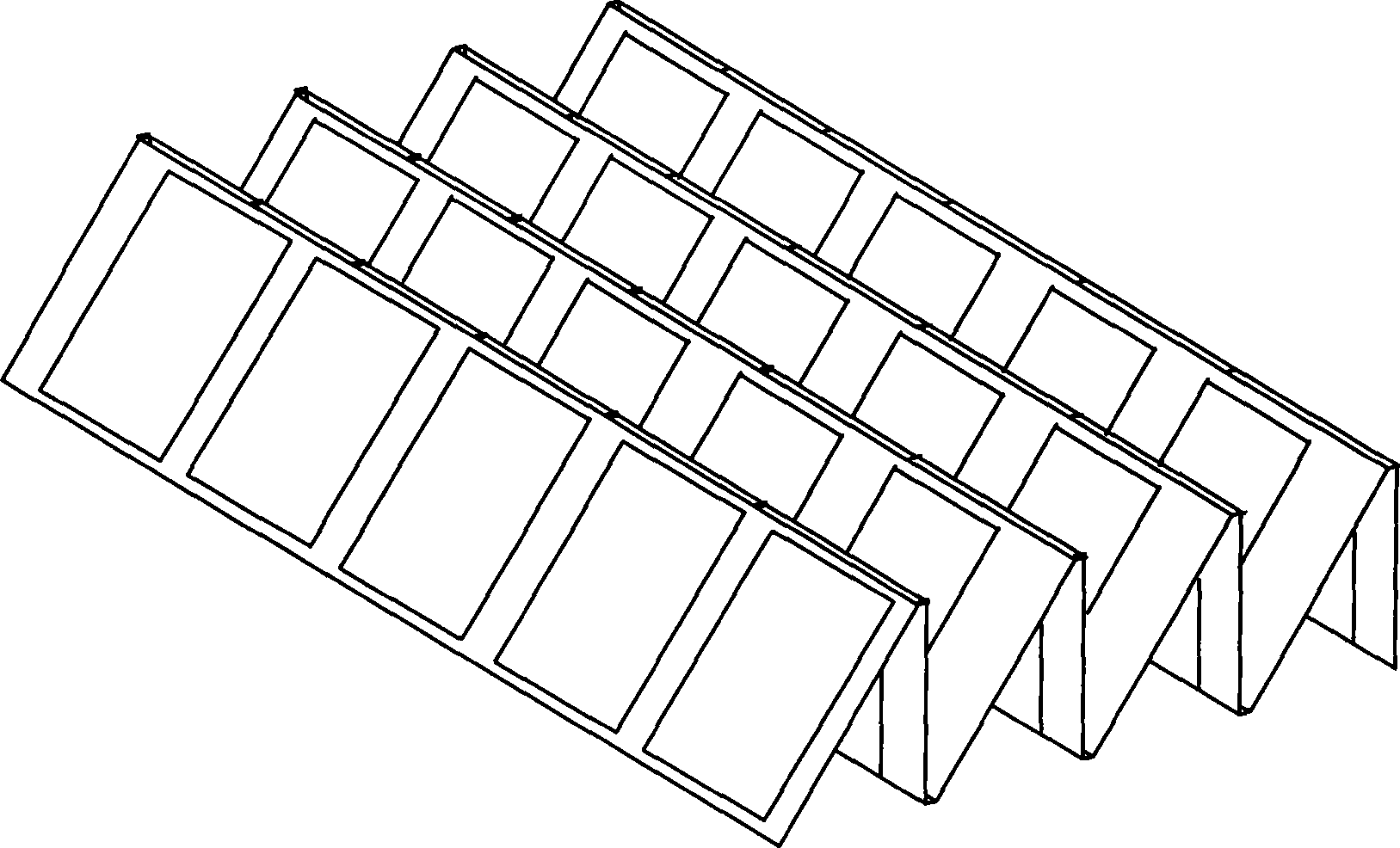

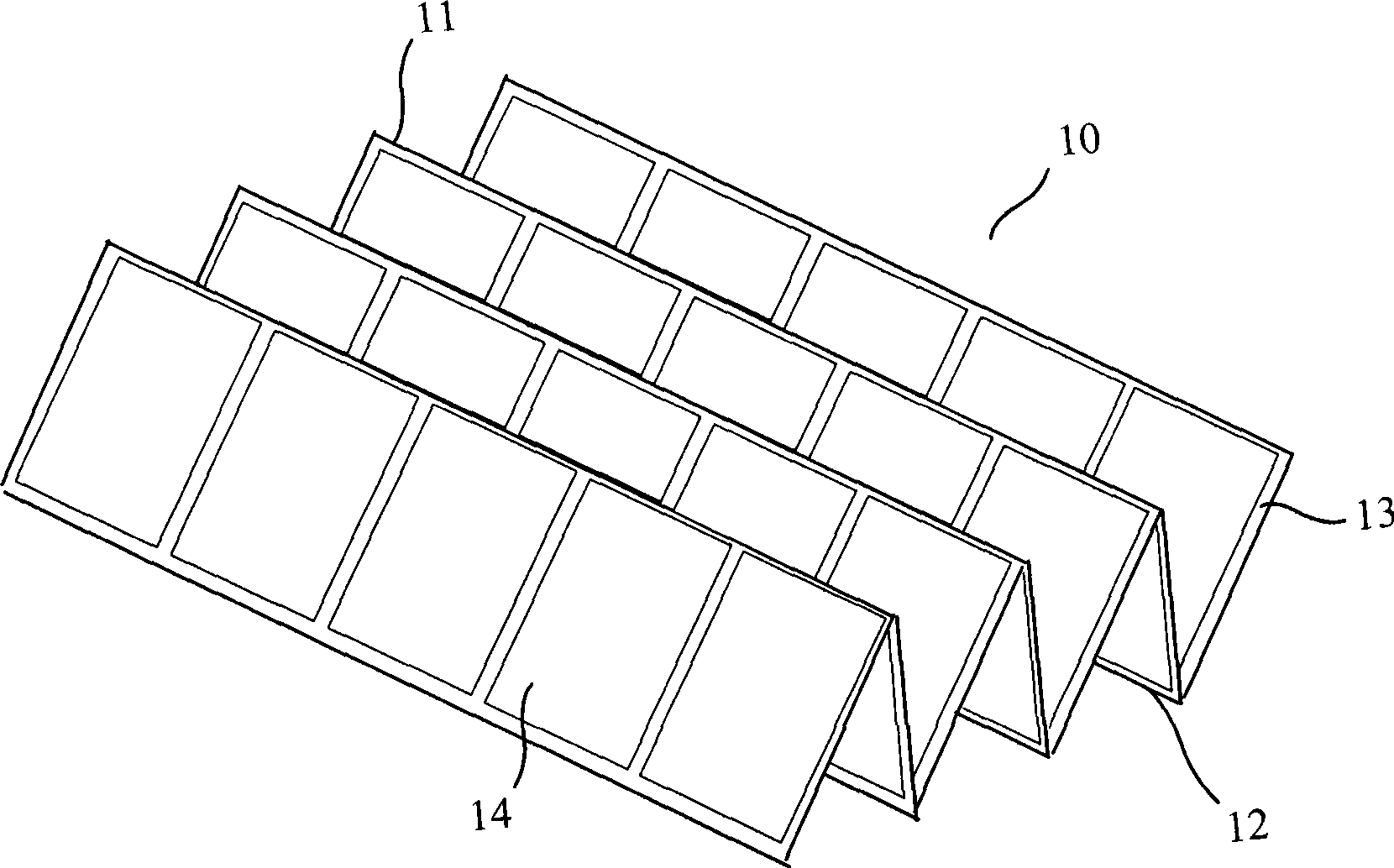

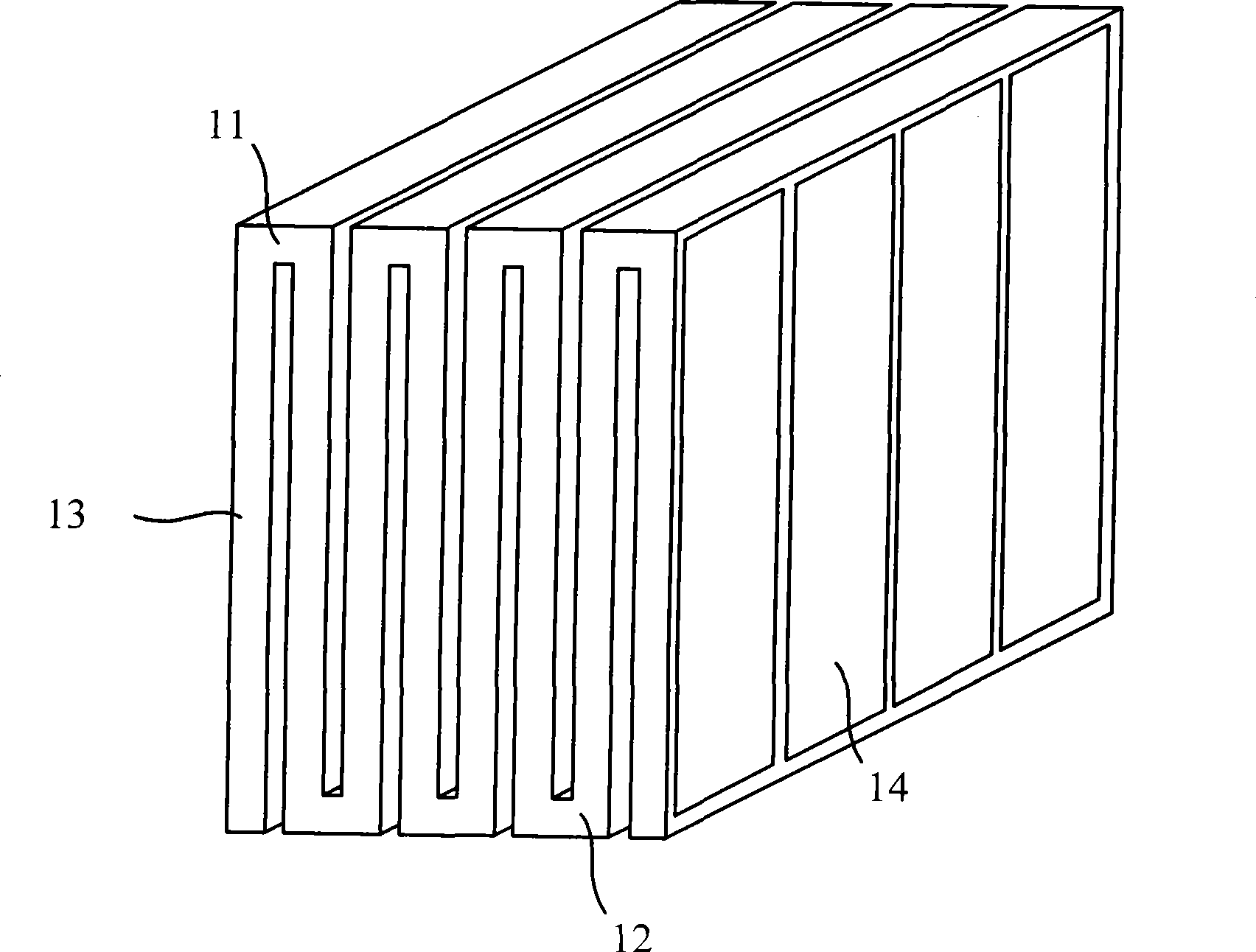

[0019] Wick support member first embodiment

[0020] figure 2 It is a schematic structural diagram of the first embodiment of the liquid-absorbent core support member of the present invention. The liquid absorbing core support member of this embodiment is used for brazing and connecting on the inner wall of the integrated heat pipe shell to support the shell and overcome the positive and negative effects of alternating positive and negative effects on the shell wall when the state of the liquid working medium in the shell changes. pressure. like figure 2 As shown, the liquid-absorbent core support member specifically includes a wavy band-shaped metal sheet 10 rolled by gears, and the part between each wave crest 11 and wave trough 12 of the wave-band-shaped metal sheet 10 is called a metal sheet segment 13 . The wave cre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com