Distributed sand feeding system and method for suspended sediment model test

A model test and sand suspension technology, which is applied in the hydraulic model and other directions, can solve the problem that it is difficult to meet the requirements of timely changes in the amount of sand added, and achieve the effect of reducing work intensity and high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

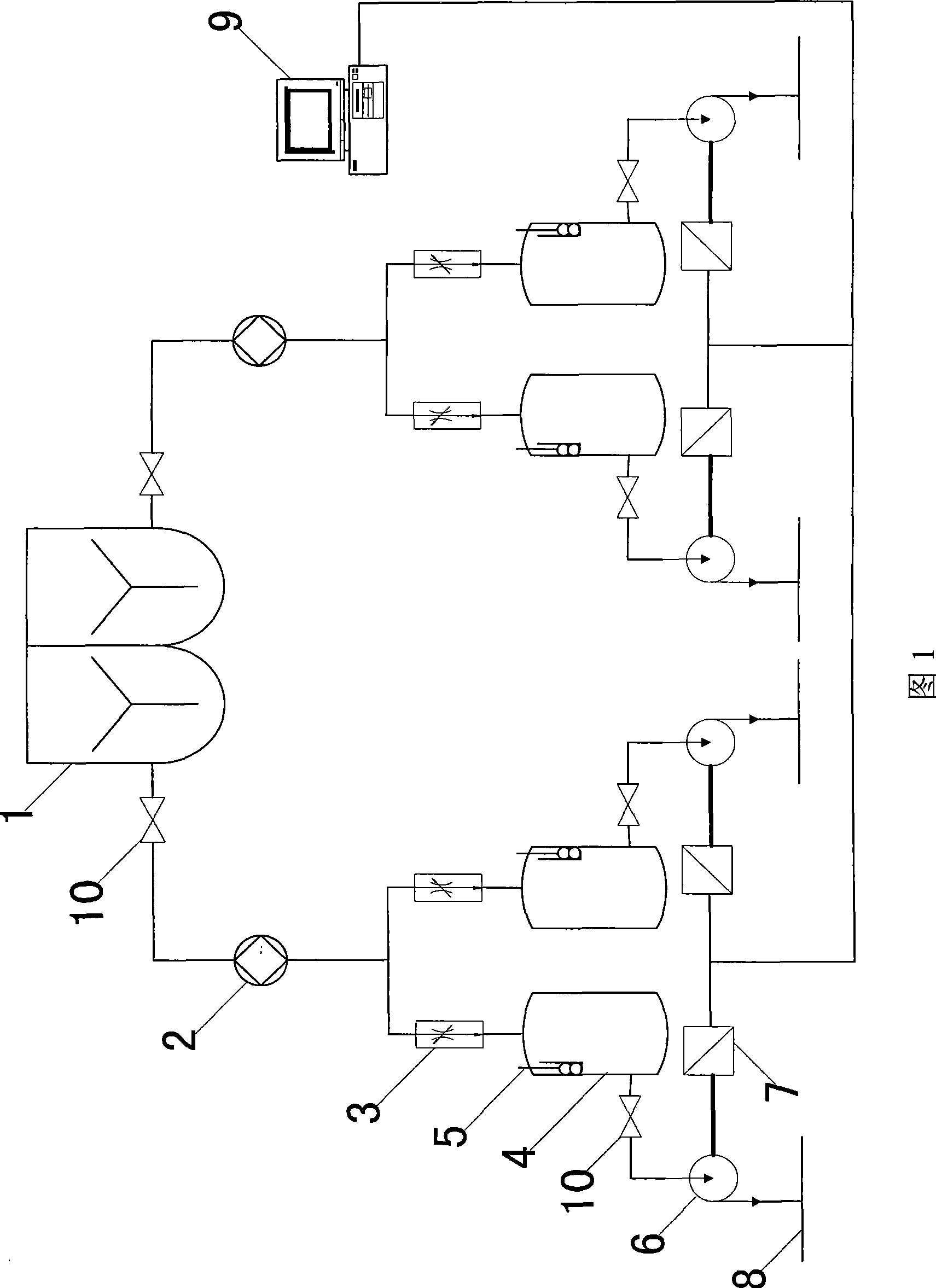

[0024] Referring to Fig. 1, what this figure reflects is one aspect of the present invention, namely the block diagram of the suspended sand model test distributed sand adding system. In order to realize the multi-section suspended sand model test, this embodiment provides four sand throwers 8, which can simulate four sections.

[0025] The mixing tank 1 has a large capacity and is installed outdoors to prepare and accommodate muddy water with sand. The mixing tank 1 is equipped with a motor-driven stirring device to keep the sand content (concentration) of the muddy water in the mixing tank 1 at a basic level. Constant, so that the model sand in the stirring tank 1 will not settle, making the concentration of the muddy water unstable, resulting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com