High elastic wool-like fabric and production method thereof

A production method and fabric technology, applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the problems of unsatisfactory consumers and low-grade products, and achieve the effect of rich colors, soft colors, and strong wool feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

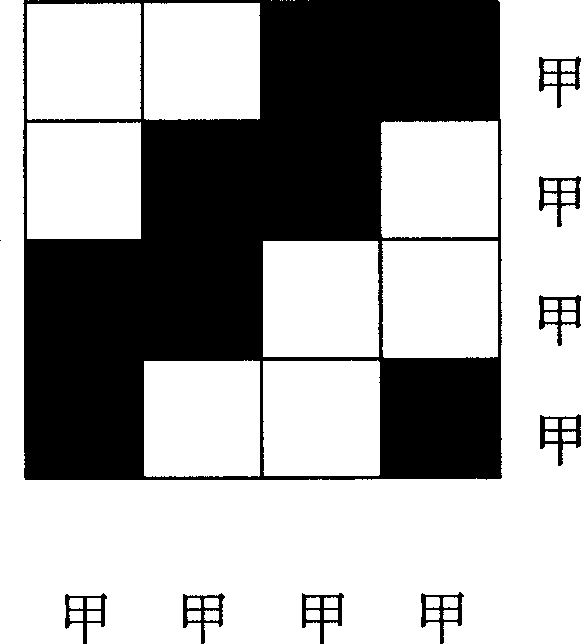

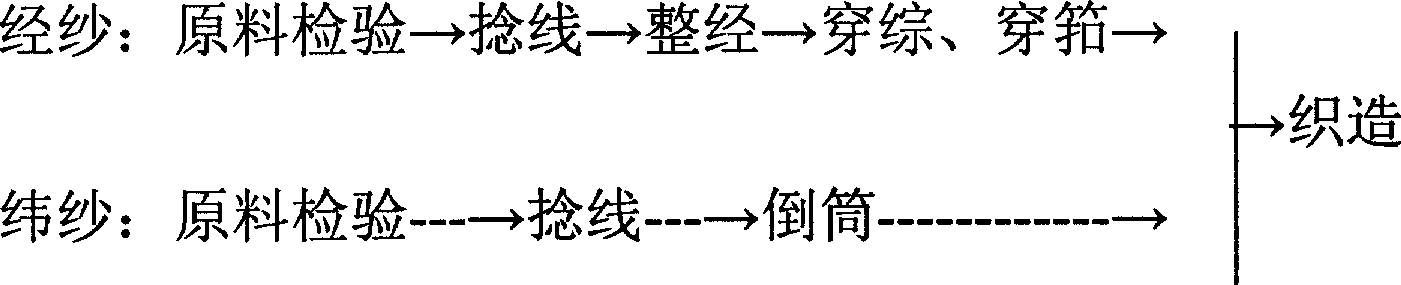

[0036] Adopt above-mentioned two kinds of yarns of proportioning A and B, the twist coefficient of A yarn is 280, and the twist coefficient of B yarn is 310, A yarn+B yarn is used for nail warp; A yarn+B yarn is used for nail weft; The twist coefficient is 420, the reed number 10# is selected for the upper machine, and the heald drawing method adopts 4 pieces of threading; threading: 2 healds / reed, and the width of the upper machine: 205cm; after the dyeing and finishing of the woven fabric, the cloth The surface is elastic enough and feels good, indicating that the weaving and dyeing process meets the requirements of the fabric (fabric such as figure 1 shown).

Embodiment 2

[0038] Adopt above-mentioned two kinds of yarns of proportioning A and B, the twist coefficient of A yarn is 290, the twist coefficient of B yarn is 320, A yarn+B yarn is used for nail warp; A yarn+B yarn is used for nail weft; The twist coefficient is taken as 450, the reed number 10.5# is selected for the upper machine, and the drawing-in method adopts 4 pieces along the heald; threading: 2 healds / reed, the upper machine door width: 205cm; after the woven fabric is dyed and sorted, the cloth The surface is elastic enough and feels good, indicating that the weaving and dyeing process meets the requirements of the fabric (fabric such as figure 1 shown).

Embodiment 3

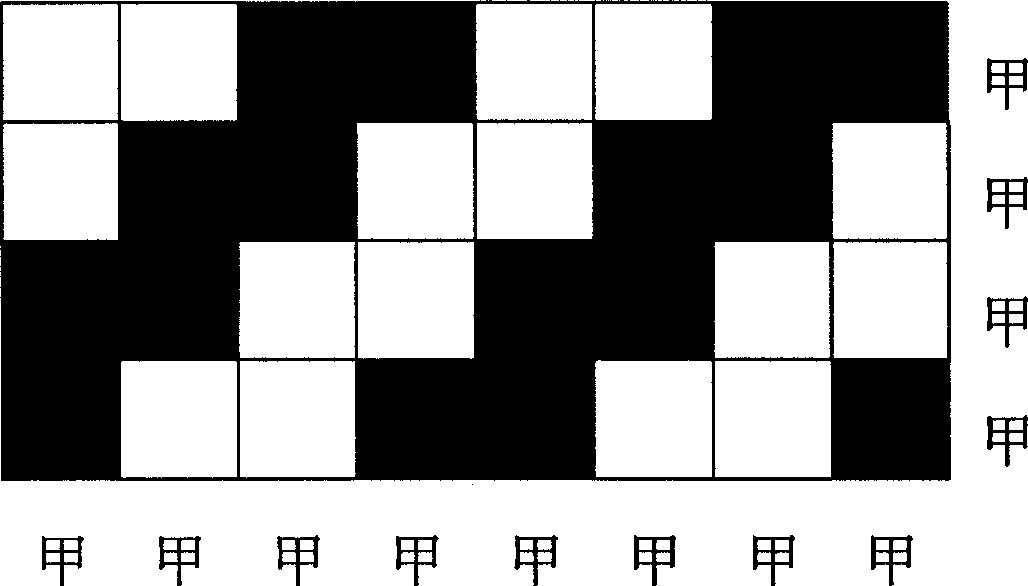

[0040] Adopt above-mentioned two kinds of yarns of proportioning A and B, the twist coefficient of A yarn is 300, and the twist coefficient of B yarn is 330, A yarn+B yarn is used for nail warp; A yarn+B yarn is used for nail weft; The twist coefficient is taken as 480, the reed number 11# is selected for the upper machine, and 8 pieces are used for threading method; threading: 2 healds / reed, and the width of the upper machine: 205cm; The surface is elastic enough and feels good, indicating that the weaving and dyeing process meets the requirements of the fabric (fabric such as figure 2 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| twist factor | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com