Hydro-upgrading method for FCC gasoline

A technology for catalytic cracking gasoline and hydro-upgrading, which is applied in the hydro-upgrading and high-sulfur fields of full-cut FCC gasoline with high olefins, and can solve the problem of poor hydrothermal stability catalyst regeneration performance, unsatisfactory catalytic stability, and non-selective properties. The problem of serious shape reaction is to achieve good desulfurization, reduce the formation of colloid, and improve the anti-knock index.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

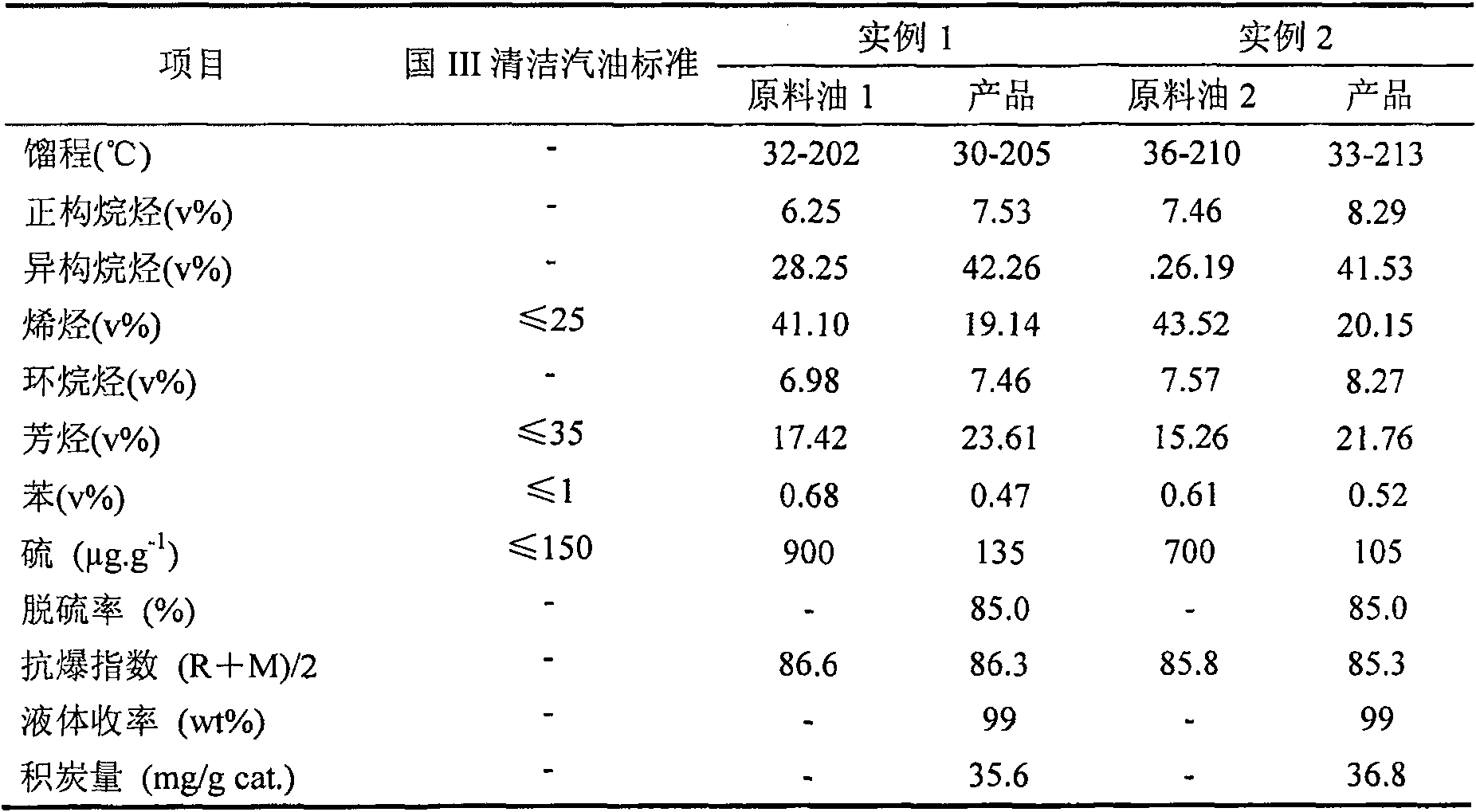

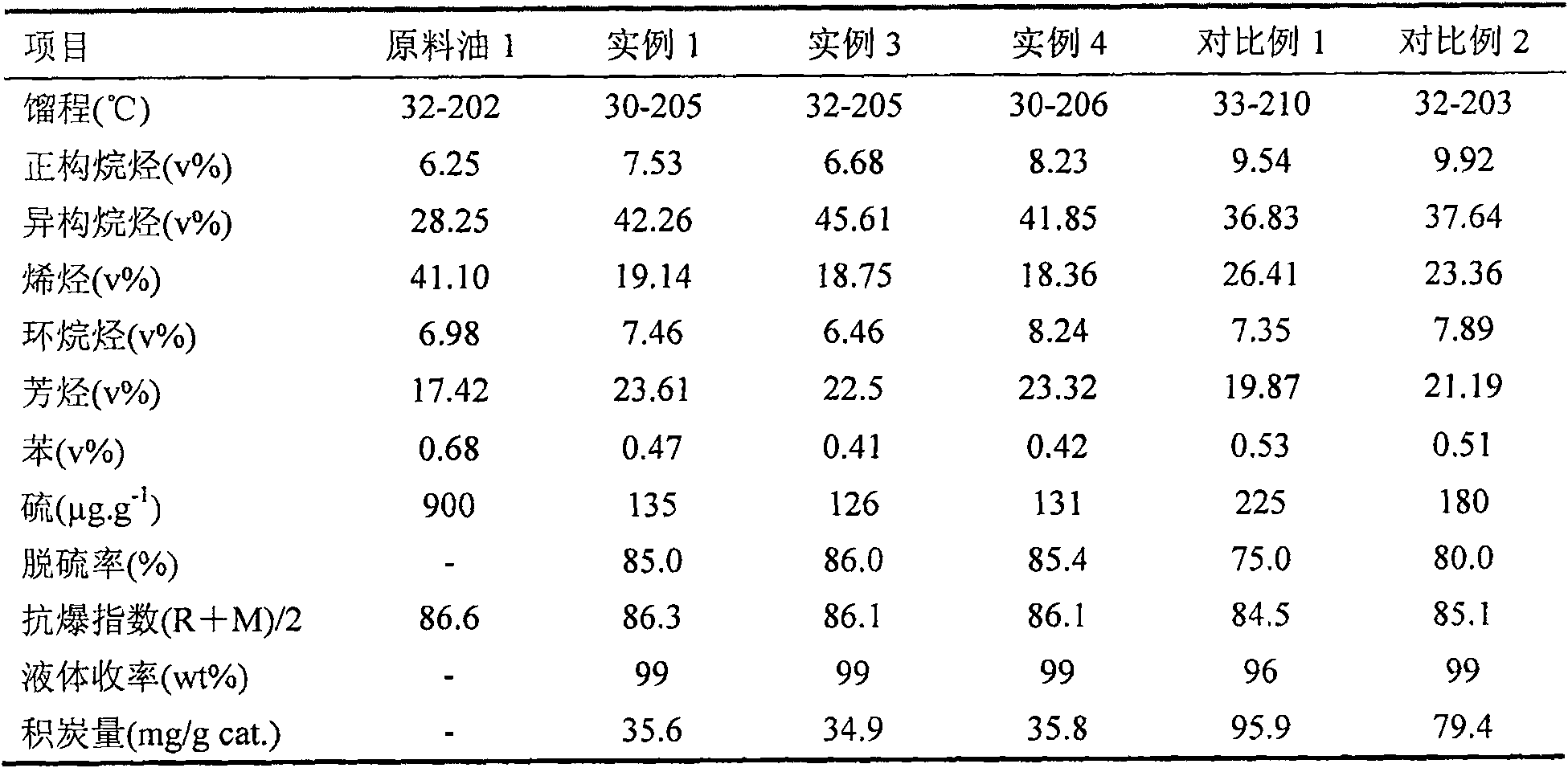

Embodiment 1

[0027] This example prepares 1wt% NiO-4wt% MoO 3 -4wt%K 2 O-1wt% La 2 O 3 / 90wt%γ-Al 2 O 3 The first-stage selective hydrodediene catalyst and 1.5wt% NiO-7wt% MoO 3 / 50wt%HZSM-5(SiO 2 / Al 2 O 3 The molar ratio is 50)-20wt%SAPO-11(SiO 2 / Al 2 O 3 The molar ratio is 0.3)-21.5wt%γ-Al 2 O 3 The second stage in-situ composite zeolite-based catalyst.

[0028] The first-stage selective hydrodediolefin catalyst was prepared by a conventional equal volume impregnation method, and an appropriate amount of K was sequentially loaded on the shaped alumina carrier according to the stoichiometric ratio. 2 O, MoO 3 and NiO and La 2 O 3 , the steps of aging, drying and roasting are required after each loading of active metal components.

[0029] The specific preparation steps of the second stage catalyst are as follows: by chemical composition (molar ratio) Na 2 O:Al 2 O 3 : SiO 2 : TEAOH (tetraethylammonium hydroxide): H 2 O=9.7:1:55:10:3500 to prepare the initial gel of...

Embodiment 2

[0035] The difference between this example and Example 1 is that the feedstock oil has an olefin content of 43v% and a sulfur content of 700μg.g -1 FCC gasoline.

Embodiment 3

[0037] The difference between this example and Example 1 is that the composition of the second-stage in-situ composite zeolite-based catalyst is different, and the catalyst composition is: 1.5wt% NiO-7wt% MoO 3 / 40wt%HZSM-5(SiO 2 / Al 2 O 3 The molar ratio is 50)-30wt% SAPO-11(SiO 2 / Al 2 O 3 The molar ratio is 0.3)-21.5wt%γ-Al 2 O 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com