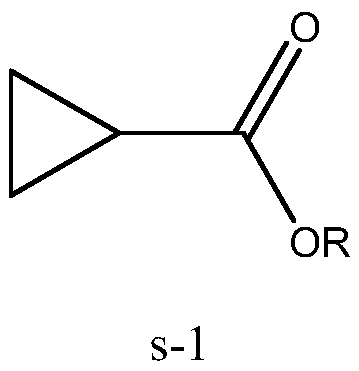

Method for Synthesizing Cyclopropaneformic Acid Ester in Low Alcohol Solubility Solvent

A cyclopropane ester and solubility technology, which is applied in the separation/purification of carboxylate, preparation of carboxylate, chemical instruments and methods, etc., can solve the problems of large amount of solvent, large demand for solvent, and difficulty in recycling , to achieve the effect of direct continuous feeding, saving solvent consumption, and convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

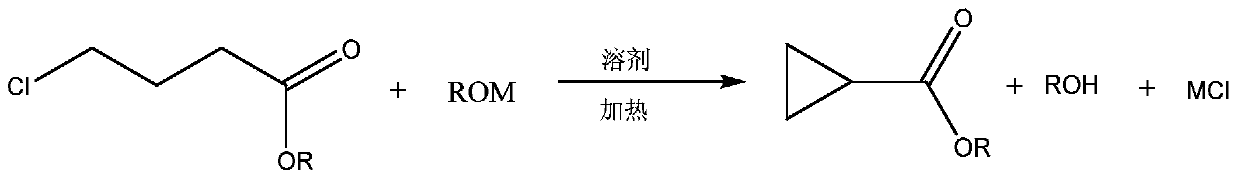

Method used

Image

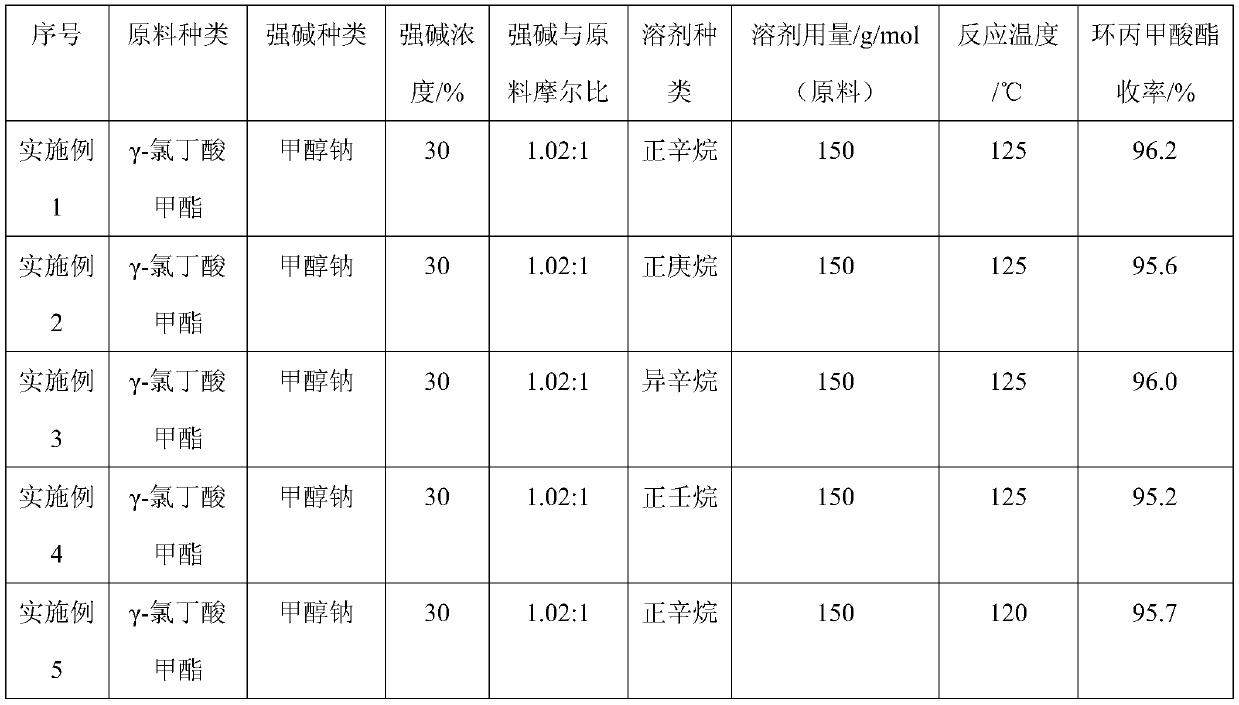

Examples

Embodiment 1

[0042] Embodiment 1, a kind of synthetic method of cyclopropyl carboxylate, carries out following steps successively:

[0043] (1), add 68.3g (0.5mol) of methyl 4-chlorobutyrate to a 250mL four-neck flask equipped with a thermometer, a stirring paddle, a dropping funnel, and a 10cm rectification column with a condensing reflux device on the top, and 75 g of alkane, after heating up to 125° C., began to drop (dropping time: 120 min) sodium methoxide methanol solution (containing 0.51 mol of sodium methoxide) with a mass concentration of 30%. Methanol and n-octane are distilled out azeotropically, and the azeotrope is condensed and separated into phases, and the methanol phase in the lower layer is continuously separated.

[0044] When no methanol phase separates out of the n-octane-sodium methylate azeotropic condensate, the cyclization reaction ends, and the cyclization reaction liquid is obtained.

[0045] (2), 82 g of the separated methanol phase was washed with 10 g of wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com