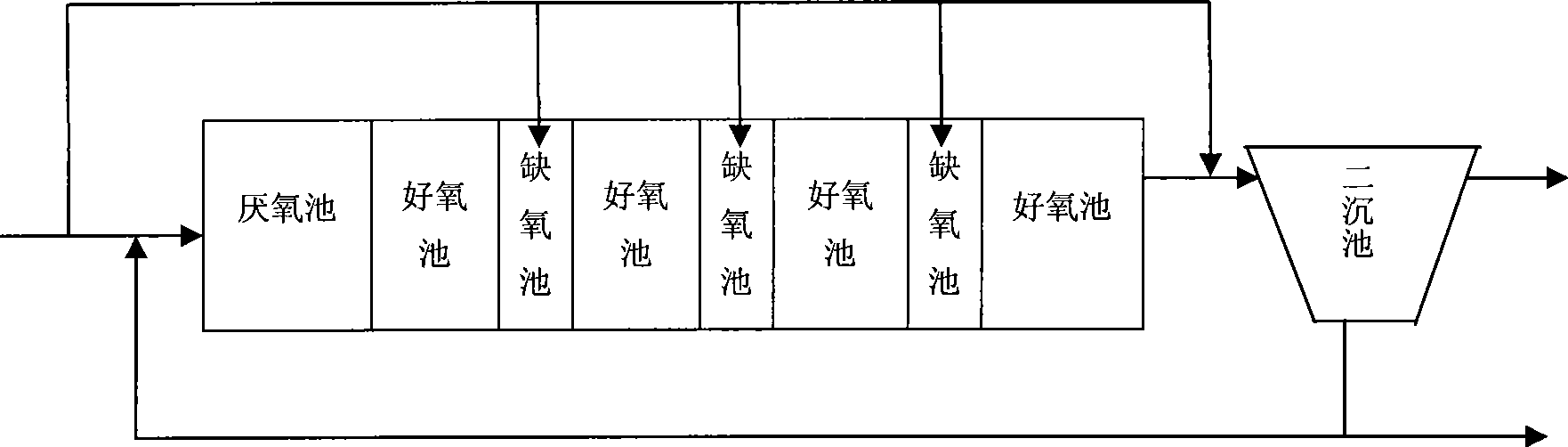

Anaerobic multi-stage aerobic-anoxic dephosphorization and denitrification process

One-stage aerobic and denitrification technology, applied in the field of anaerobic multi-stage aerobic anoxic anoxic dephosphorization and denitrification process, can solve the problems of increasing investment and operating costs, slow growth of nitrifying bacteria, long nitrification time, etc. The effect of building volume, improving capture rate and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] As shown in the figure, the sewage enters in two parts. A part of about 30% of the sewage is mixed with the sludge and then enters the anaerobic tank. In addition, most of the sewage goes beyond the anaerobic tank in multiple points and enters directly connected to multiple aerobic tanks. Multiple anoxic tanks are used for denitrification, and there are 1-19 water inlet points beyond the anaerobic tank to enter the multiple anoxic tanks. After the denitrification is completed, the remaining small part of the sewage and the mixed liquid from the last aerobic tank enter the secondary settling tank for mud-water separation, and the remaining small part of the sewage directly entering the secondary settling tank beyond the biological reaction tank is 5%-20%. In the mud-water separation process, continue to complete the denitrification reaction, reduce the nitrite nitrogen and nitrate nitrogen in the return sludge and effluent, and discharge the remaining sludge regularly.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com