Method for preparing polymer-based damping composite material capable of being designed into alternate laminar structure

A damping composite material and composite material technology are applied in the field of preparation of polymer damping composite materials, which can solve the problems of difficulty in forming a dual-continuous phase structure, difficult phase morphology, and poor damping effect, and achieve excellent damping performance and high damping factor. , the effect of wide effective damping range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

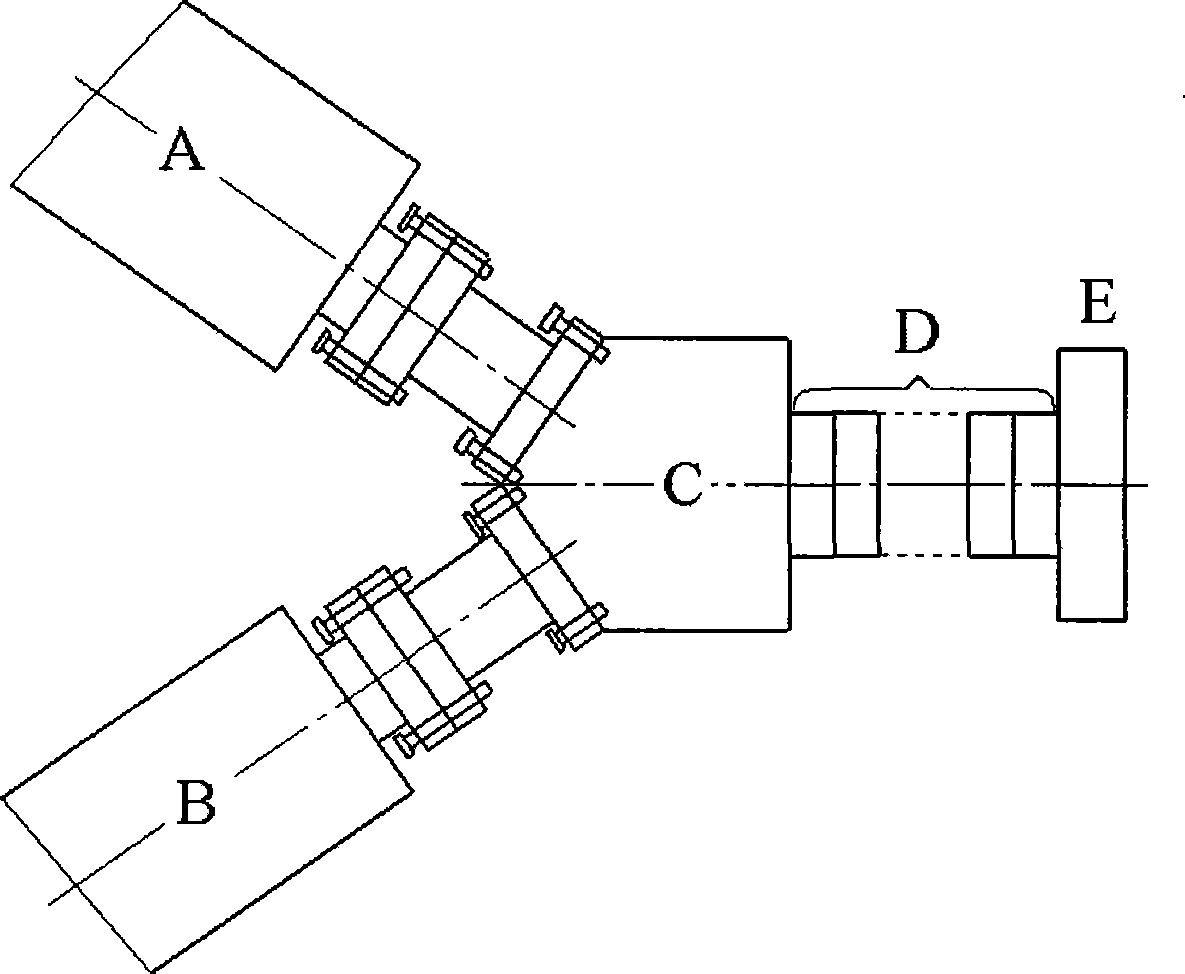

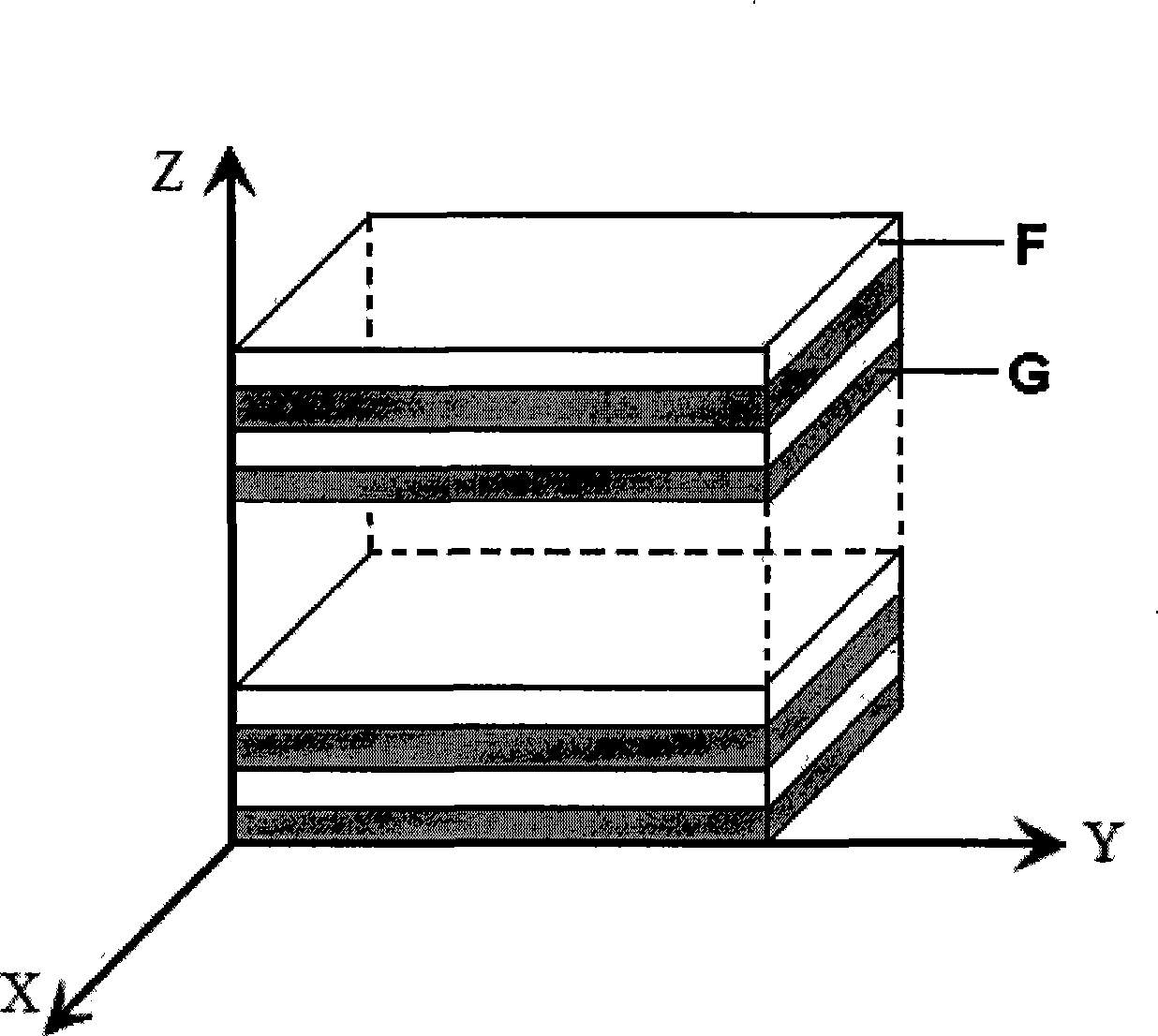

[0037] The two polymer materials are chlorinated butyl rubber compound and EPDM rubber compound respectively, which are respectively put into two extruders of the micro-layer co-extrusion device, and the speed ratio of the extruders is 1:1. The temperature of each section of the extruder is controlled between 80 and 90°C. The temperature of the converging unit C, the split unit D and the exit die E are all about 90°C. Using 5 split units, the material extruded from the die There are 64 layers, which are then vulcanized at about 170°C for about 15 minutes to obtain a chlorobutyl rubber / EPDM rubber damping composite. The damping factor of this material is 1.12, the effective damping range is -55~-10°C, and a new damping peak appears between 10°C and 20°C, the tensile strength is 15MPa, and the elongation at break is 850%. As a comparison, the damping factor of the damping material prepared by the traditional method is 0.82, the effective damping range is -47 to -22°C, the tensil...

Embodiment 2

[0039] The two polymer materials are butyl rubber compound and EPDM compound, which are put into two extruders of the micro-layer co-extrusion device respectively. The extruder speed ratio is 1:2. The temperature of each section of the machine is controlled between 80 and 90°C. The temperatures of the converging unit C, the stacking unit D and the outlet die E are all about 90°C. Using 4 stacking units, a 32-layer material is prepared, and then in Vulcanize at about 170°C for about 15 minutes to obtain a butyl rubber / EPDM rubber damping composite material. The material has a damping factor of 0.95, an effective damping range of -53 to -16.5° C., a tensile strength of 13.6 MPa, and an elongation at break of 800%.

Embodiment 3

[0041] The two polymer materials are petroleum resin-filled chlorinated butyl rubber compound and EPDM rubber compound respectively, and the weight content of petroleum resin in the chlorinated butyl rubber is 20%. The two materials are respectively put into the two extruders of the micro-layer co-extrusion device. The extruder speed ratio is 2:1. The temperatures of D and exit die E are both about 90°C. Using 3 stacked units, a 16-layer material is prepared, and then vulcanized at about 170°C for about 15 minutes to obtain petroleum resin filled chlorobutyl rubber / three Ethylene propylene rubber damping compound. The damping factor of this material is 1.23, and the effective damping range is -47~10℃

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com