Straw packed microreservoir forage

A technology of straw and grass shreds, applied in animal feed, animal feed, fungi, etc., can solve the problems of high waste rate, lack of straw forage, waste of resources, etc., and reduce the probability of mildew and protein content The effect of increasing and improving the nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

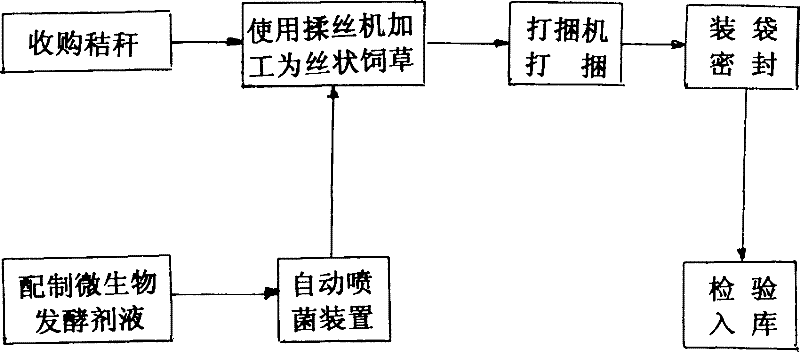

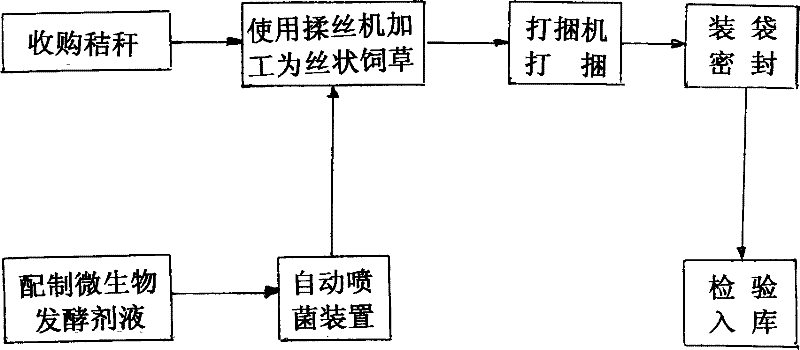

[0033] Referring to accompanying drawing, the specific process of making this stalk bagged micro-storage forage grass is:

[0034] 1. Main material preparation: use the straw extruding and kneading machine to process the net-selected fresh corn stalks into green straw grass shreds with a width of 3-5mm and a length of 3-10cm;

[0035] Two, the preparation of microbial starter: utilize Lactobacillus plantarum as the culture strain to prepare microbial starter by solid fermentation culture method and liquid fermentation culture method respectively, wherein

[0036] 1. Obtain dry bacteria by solid fermentation culture method:

[0037] 1.1 The solid medium is the carrier for the growth of the strain, which can provide the required nutrient carbon source and nitrogen source for the strain. The composition and content range of the raw materials are: 65% of wheat bran, 22.5% of corncob powder, Rice husk powder 10%, sugar 1.0%, ammonium sulfate 1.5%.

[0038] 1.2 Method steps: mix t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com