Getter composition and device for introducing of mercury into fluorescence lamp for BLU

A technology for introducing a device and a composition, which is applied in the directions of electric tube/lamp degassing, discharge tube/lamp manufacturing, and gas discharge lamp components, etc., can solve the problems of increasing manufacturing cost, serious dust, and low mercury release effect. , to achieve the effect of improving the working environment and eliminating environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

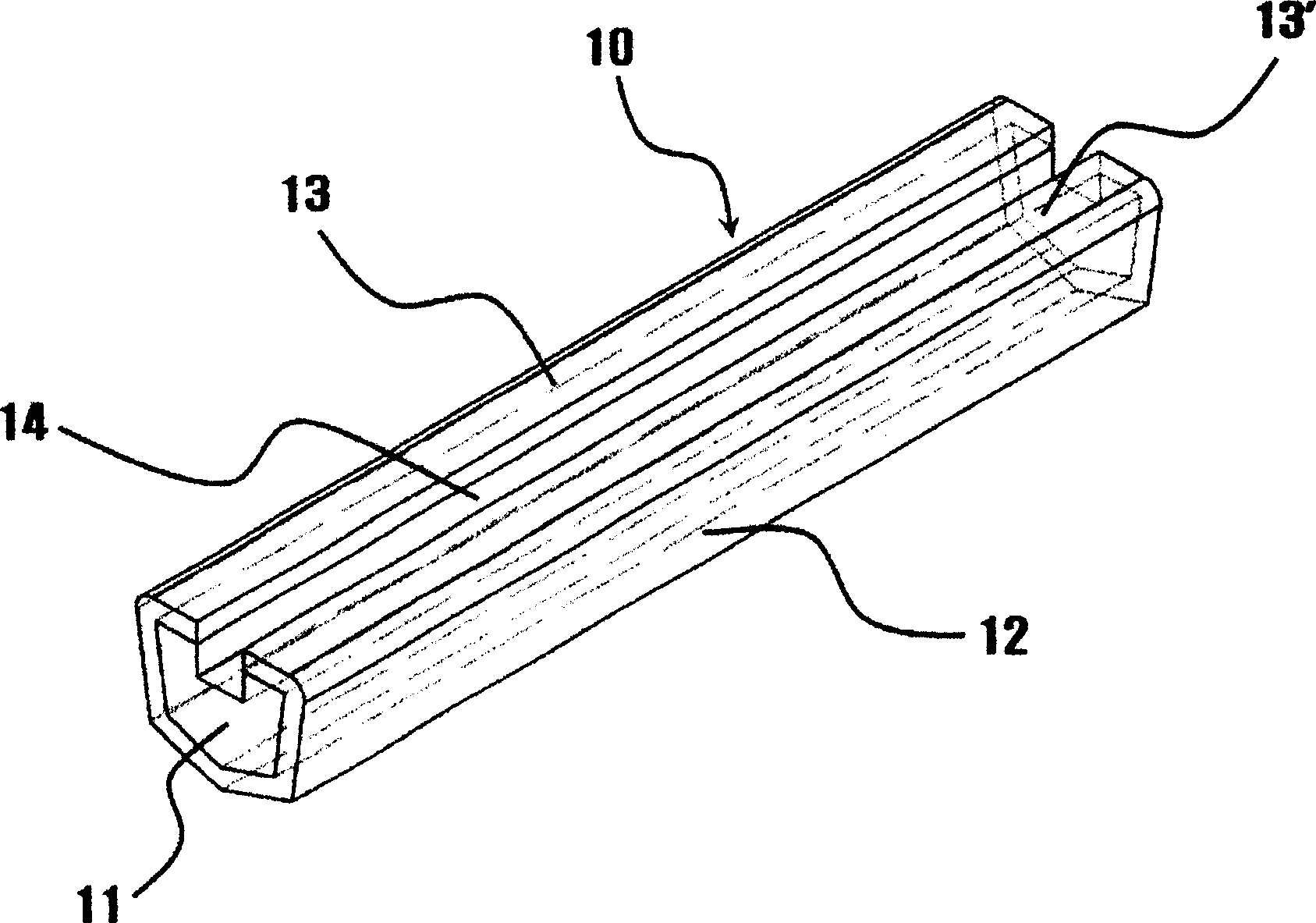

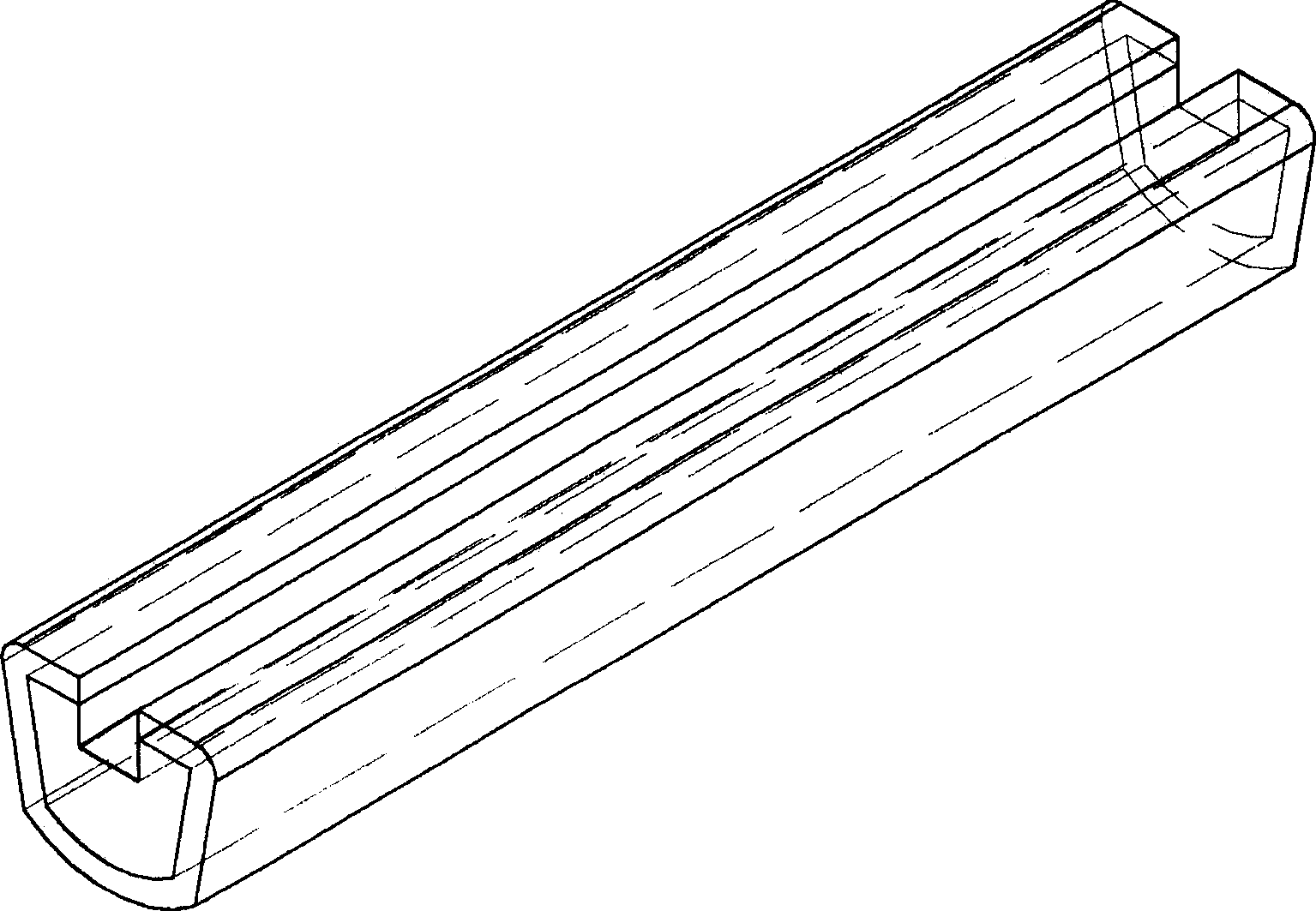

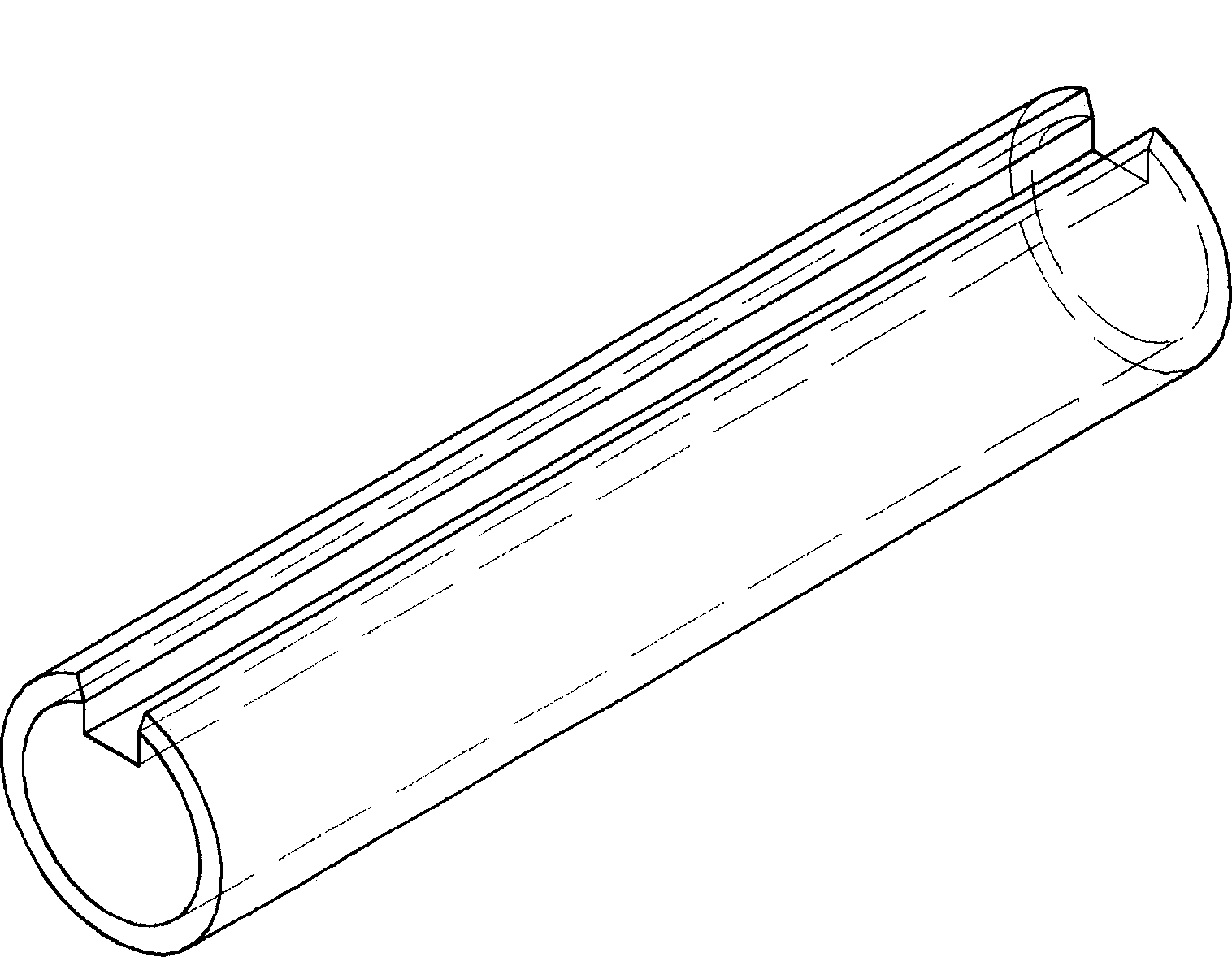

Method used

Image

Examples

Embodiment 2

[0066] Example 2 is an example in which the content of Zr and Al was reduced in the composition of Comparative Example 1, and 2% by weight of Ti was added. After adding Ti, it can be seen that the mercury release rate is 1% higher than that of Comparative Example 1.

Embodiment 3

[0067] Example 3 is an example in which 2 wt % Ta is added to the composition of Example 2. Compared with Example 2, the mercury release efficiency was increased by 4% due to the addition of Ta.

[0068] In addition, when Example 1 and Example 3 are compared, even in a composition containing 2 wt % Ta, the mercury release rate can be improved by reducing the Zr and Al contents and adding 2 wt % Ti.

Embodiment 4

[0069] In Example 4, 1 wt % of Fe was added to the composition of Comparative Example 1. Compared with Comparative Example 1, the mercury release rate of Example 4 was increased by 2%.

[0070]In Examples 5 and 6, in the composition of Comparative Example 1, 2 wt % of Ta was added, and Fe was added in a small amount to produce a getter composition. In this case, the mercury release rate was 6 to 7% higher than that of Comparative Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com