Test block special for butt-jointed seam ultrasonic wave climbing flaw detection of heterogeneity steel minor diameter tube

A technology for butt welds and small diameter pipes, which is applied in the direction of material analysis, measuring devices, and instruments using sonic/ultrasonic/infrasonic waves. Quality inspection, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

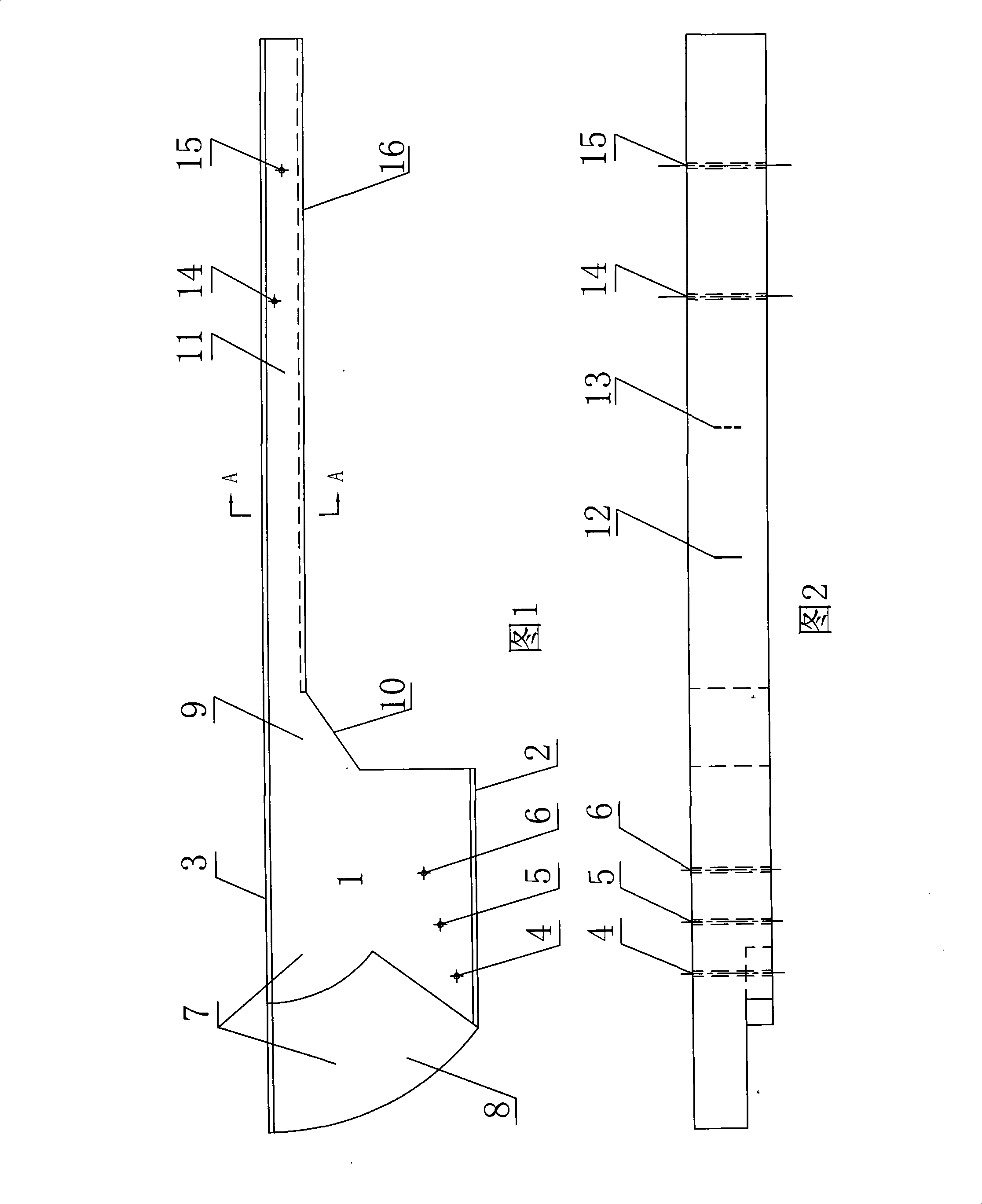

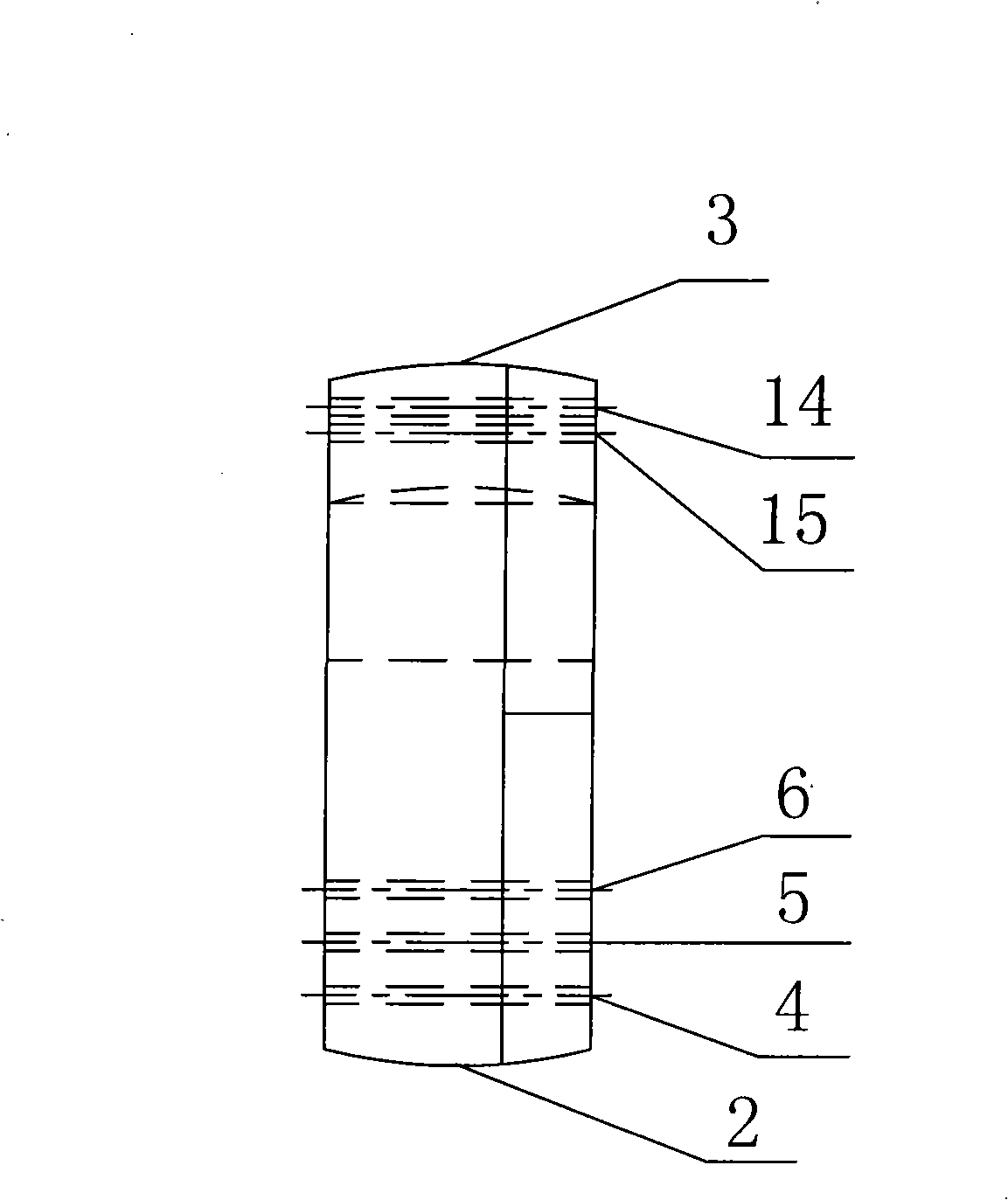

[0018] Example: As shown in Figures 1-4, the special test block for ultrasonic creeping wave flaw detection of dissimilar steel small-diameter pipe butt welds includes a knife body 1 and a knife handle 11. The knife body 1 includes a knife head 8, a knife back 3 and a knife edge 2. The knife The shank 11 is connected to the blade back 3 side of the cutter body 1 through the connecting body 9. The blade back 3 and the blade edge 2 of the cutter body 1 are convex arc surfaces with the same curvature as the outer circle of the small diameter tube. Transverse through holes 4, 5, 6; when transverse through hole 6 is used alone, measure the directivity parameters of the longitudinal wave beam and the transverse wave beam of the creeping wave probe on the curved surfaces of the blade edge 2 and the blade back 3 respectively.

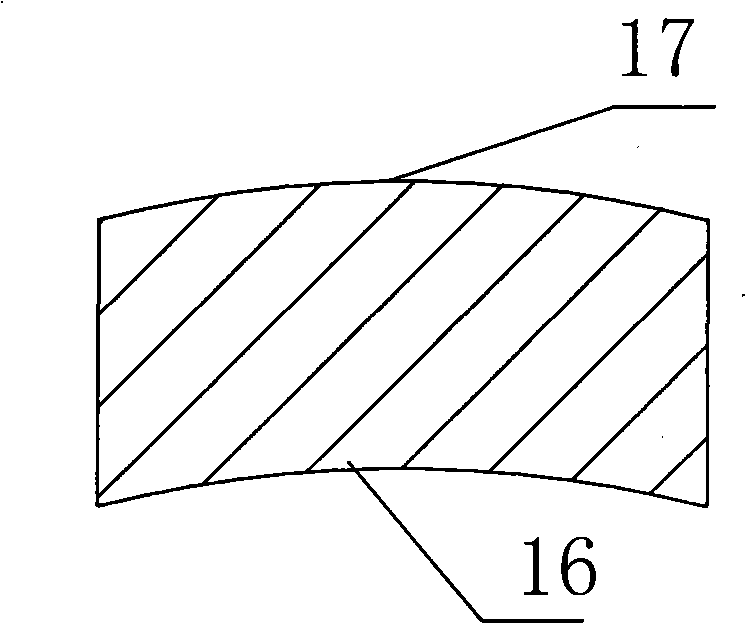

[0019] The cutter head 8 is formed by stacking two concentric fan surfaces with a diameter difference of one time in the same direction. The lower surface is r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com