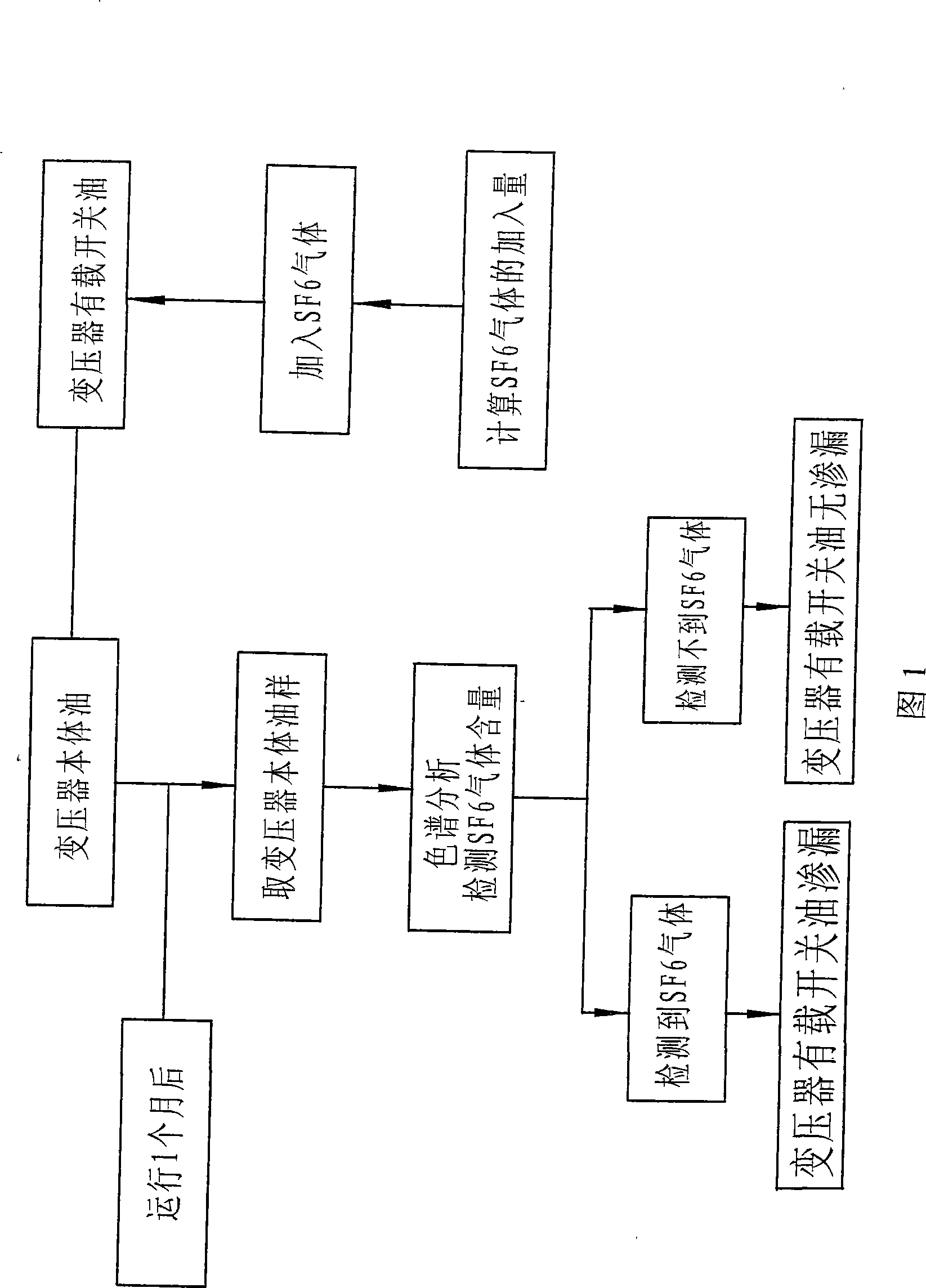

Method for detecting transformer on-load tap changer insulating oil leakage by SF6 gas

A technology of on-load tapping and gas detection, which is applied in the detection field, can solve problems affecting power safety production, transformer operation status, and increased maintenance costs, so as to reduce unplanned power outages and limit load time, avoid misjudgment of accidents, The effect of reducing labor intensity and unsafe factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

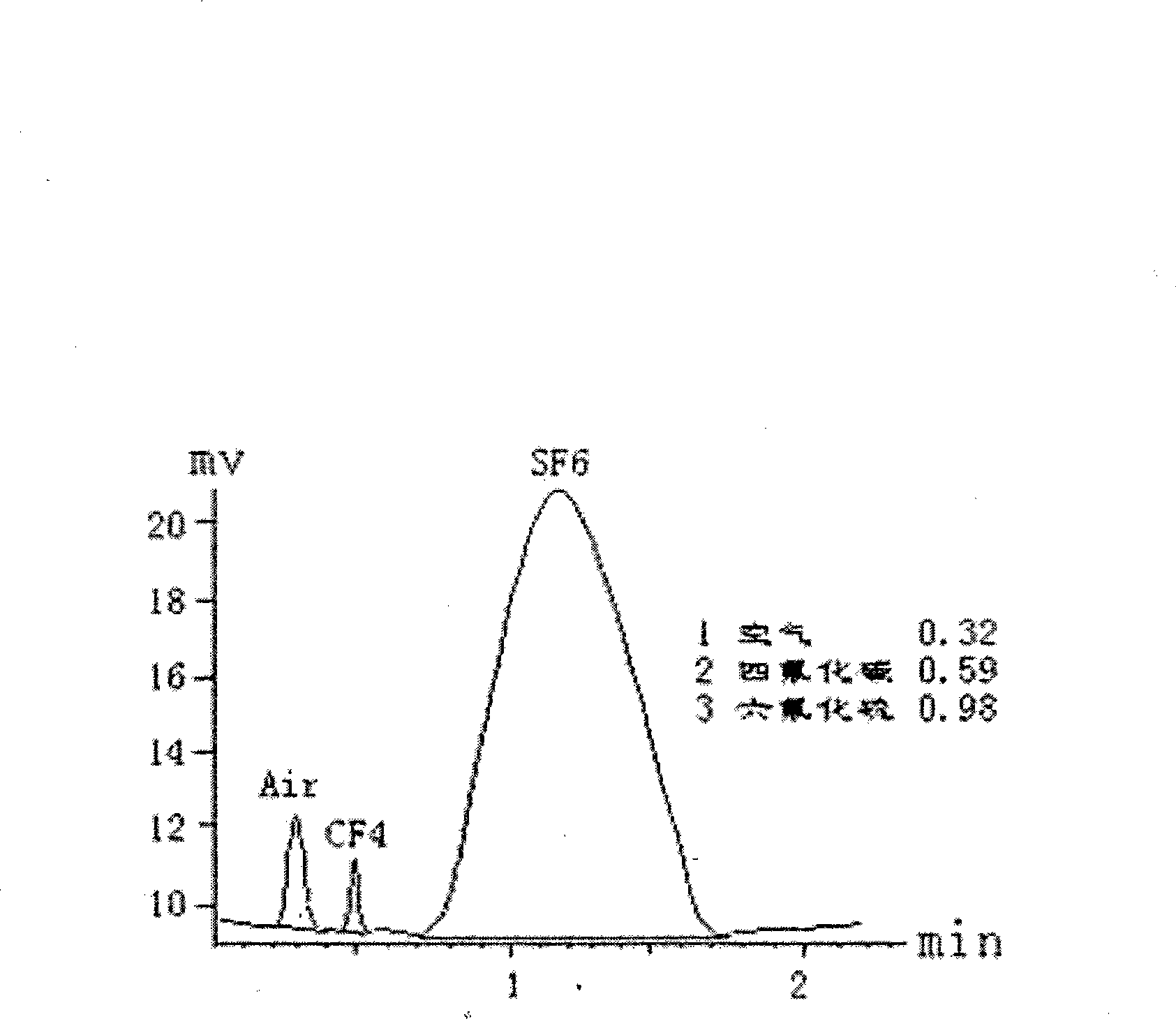

Embodiment 1

[0100] Take 50 tons of transformer body oil and 500 kg of tap changer insulating oil as an example:

[0101] Step 1. Determine the SF to add to the on-load tap-changer 6 Gas volume:

[0102] According to SF 6 Gas stability detection solubility 20μL / L and adding SF to insulating oil 6 The maximum volume percentage of gas is 6%, and the SF in the insulating oil of the on-load tap-changer is calculated according to the following formula 6 Minimum and maximum volumes for gases:

[0103] V=(M 1 +M 2 )÷0.89×20×10 -6

[0104] =(50000+500)÷0.89×20×10 -6 =1.1(L)

[0105] V'=M 2 ÷0.89×6%=500÷0.89×6%=33.7(L)

[0106] In the formula: the minimum volume of V-SF6 gas added, the unit is L;

[0107] m 1 - is the oil weight of the transformer body, in Kg;

[0108] m 2 - is the weight of transformer on-load switch oil, in Kg;

[0109] V' - the maximum volume of SF6 gas added, unit L;

[0110] Due to the addition of a minimum volume of SF to the insulating oil of the on-load tap-c...

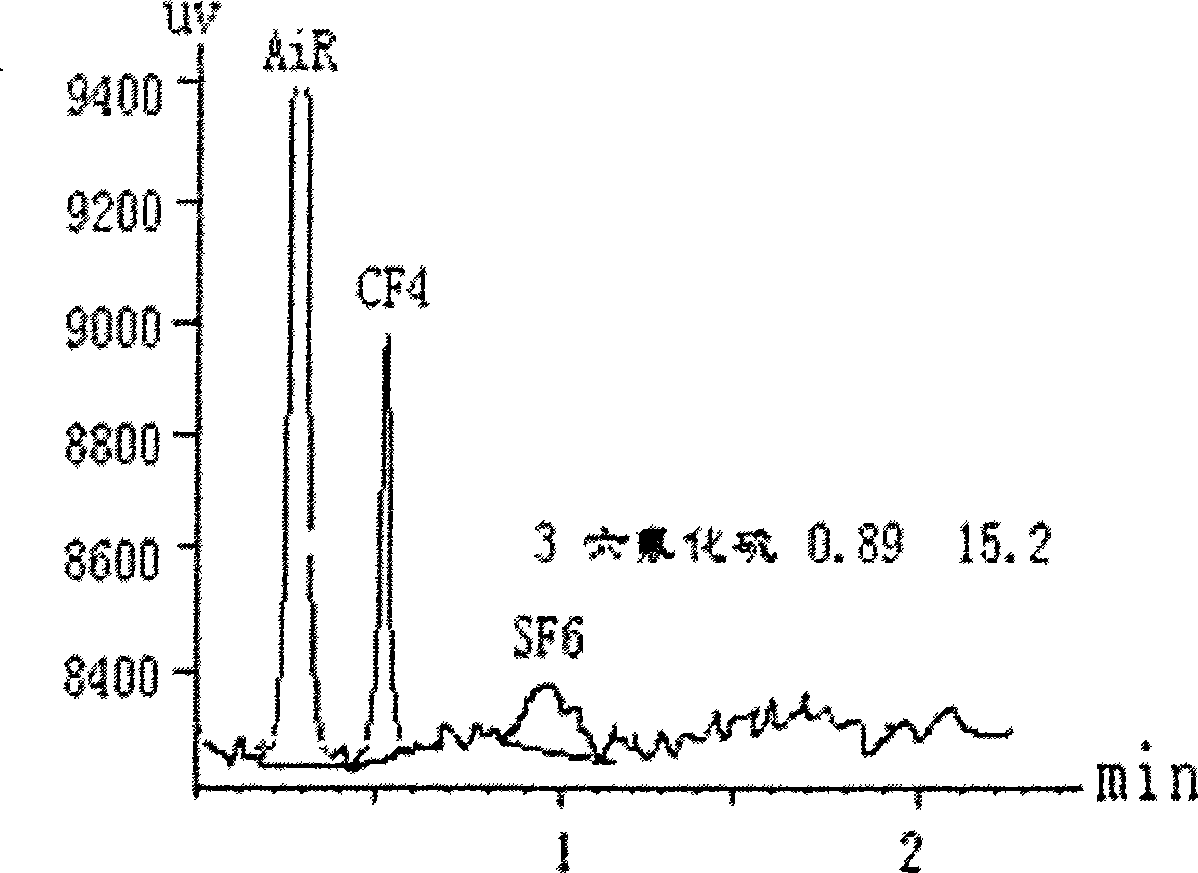

Embodiment 2

[0125] Choose 110kV to build a substation, the transformer model is: SFZLB-31500 / 110, and the production number is: 818L06-1. The transformer has been put into operation since 1983. During operation, it was found that the oil weight of the on-load tap-changer was 400kg, and it was suspected that the oil chamber of the on-load tap-changer leaked into the main body;

[0126] Step 1: Determine SF 6 The amount of gas added:

[0127] Volume of on-load tap-changer: 400×0.89=449L

[0128] Addition amount of SF6 gas: 449×6%=27L

[0129] Step 2: Inject 27L of SF into the on-load tap-changer oil 6 gas:

[0130] Choose SF with a purity of 99.99% 6 Gas and precision regulating valves are connected with stainless steel pipes, and one side is connected to SF 6 The output port of the pressure reducing valve is connected to the air release nozzle of the gas relay of the on-load tap-changer on one side. Adjust the precision needle valve so that the SF 6 The gas flow rate is controlled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com