Slit type baking house hot-air stove

A technology of hot blast stove and barn, which is applied in the field of drying equipment, and can solve problems such as complicated operation and maintenance, low thermal efficiency, and inability to burn multiple fuels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

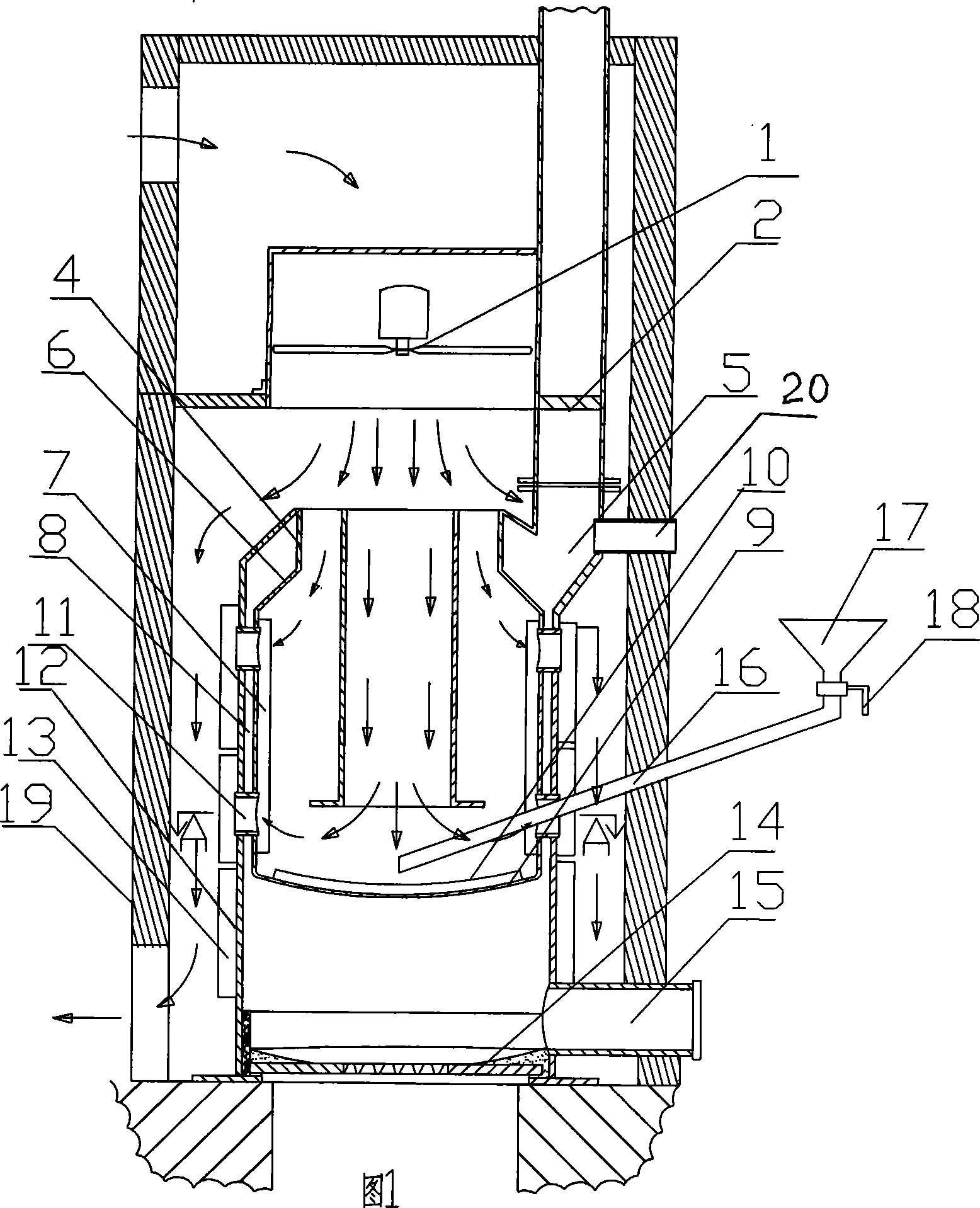

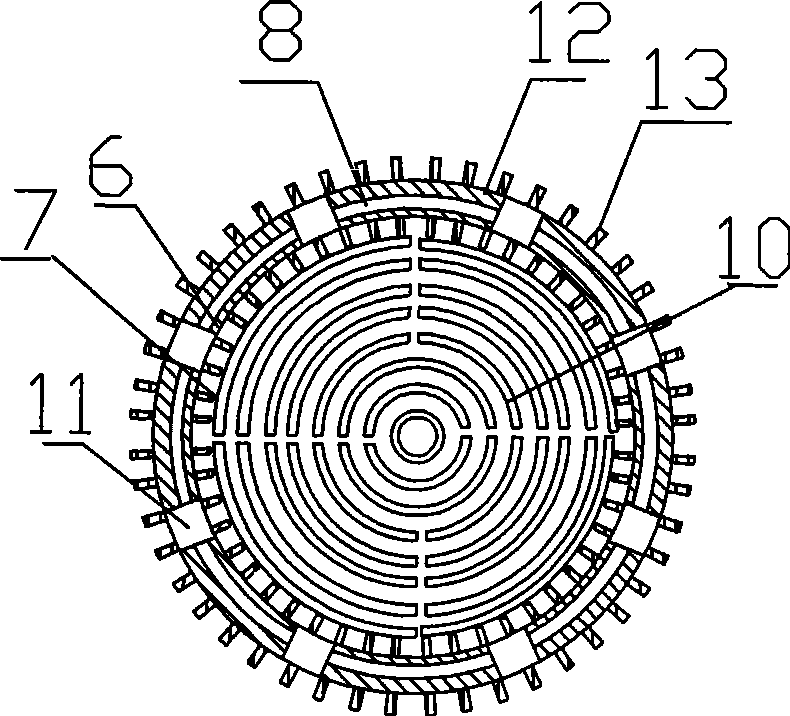

[0014] As shown in Fig. 1, a kind of slotted barn hot air stove, the hot air stove is installed in the hot air heat exchange chamber 19 at the end of the barn, mainly consists of a chimney 2, an air duct 4, an inner cylinder 6, an outer cylinder 12, and a feeding port. 15 and fire grate 14 are formed, fan 1 is arranged on the top of outer cylinder 12, and chimney 2 communicates with the top of outer cylinder 12, and fire grate 14 is positioned at the bottom center of outer cylinder 12, and feeding port 15 is positioned at the bottom of outer cylinder 12, and can use existing There is a conventional automatic coal feeding device to realize the addition of combustion. The diameter of the outer cylinder 12 is larger than that of the inner cylinder 6. The opening at the top of the inner cylinder 6 is sealed with the outer cylinder 12. There is a gap between the outer circumference of the inner cylinder 6 and the inner circumference of the outer cylinder 12. Flush the flue 5, the en...

Embodiment 2

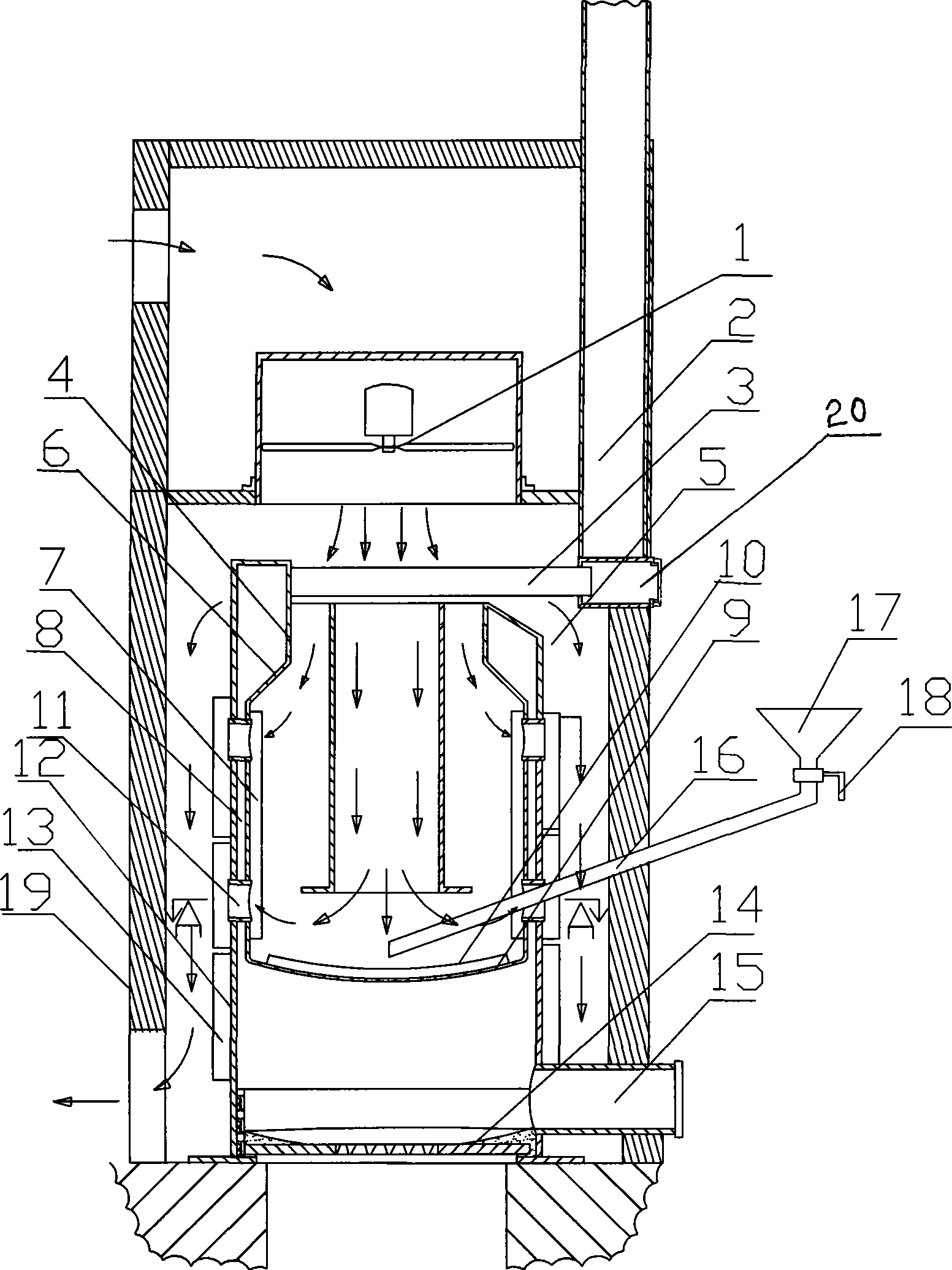

[0016] Such as figure 2 As shown, a slotted barn hot blast stove, the chimney 2 communicates with the flue gas waste heat device 3, and the flue gas waste heat device 3 has more than two pipes arranged in parallel above the top of the inner cylinder 6, and one end communicates with the flue gas channel. At the joint between the flue gas waste heat device and the chimney, a soot cleaning hole 20 is reserved, and the other end communicates with the chimney 2 . All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com