Internal thermal insulation house of integral spray finishing costalia concrete structure and construction method thereof

A technology of concrete structure and construction method, applied in the direction of building structure, construction, etc., can solve the problems of wrapping, surface cracking, waste of wood, steel and labor, etc., to reduce project cost, shorten construction period, and have good seismic effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

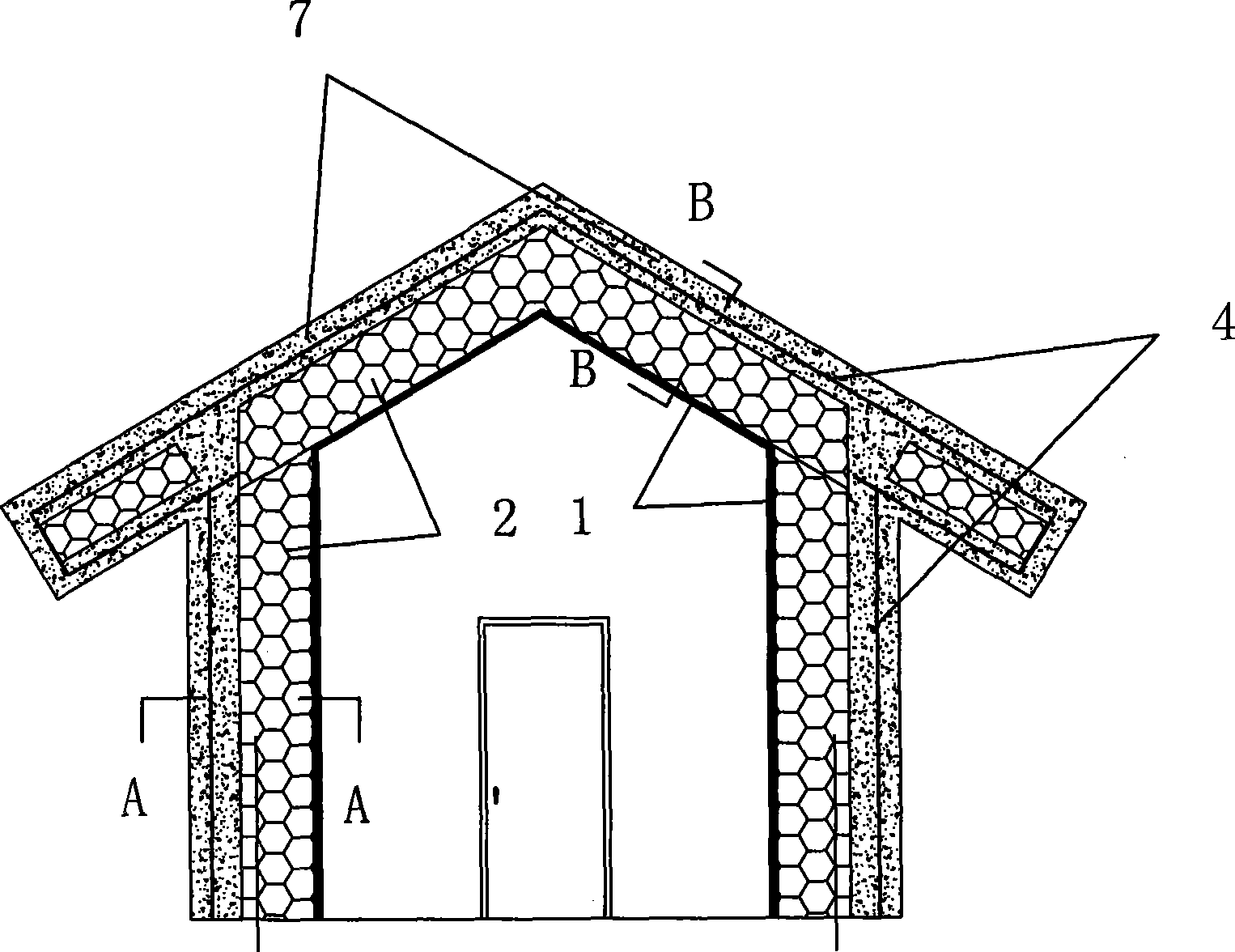

[0036] figure 1 The schematic diagram of the construction structure of the internal thermal insulation house with integrally sprayed ribbed concrete is shown, in the figure:

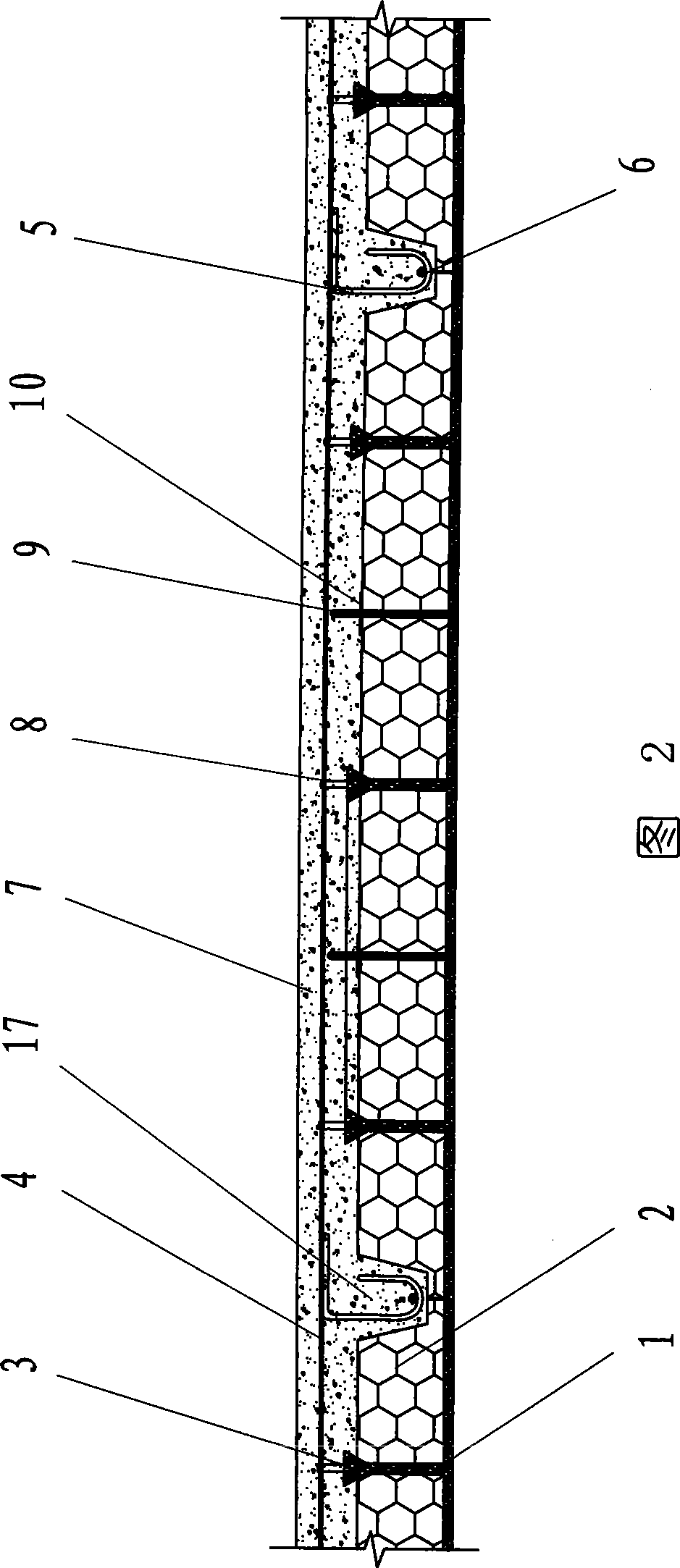

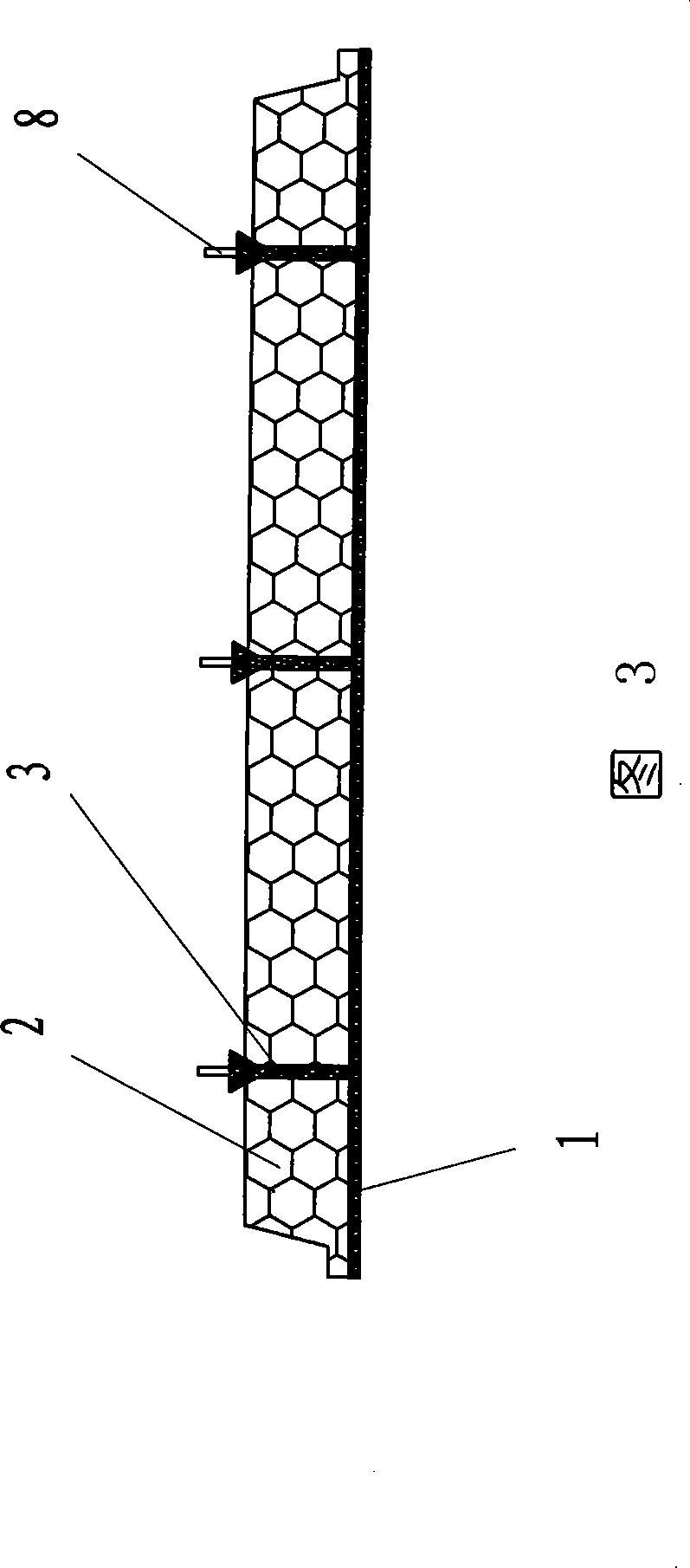

[0037] The thermal insulation inner wall is connected by the thermal insulation layer 2 and the inner wall surface layer 1, and the outer surface of the thermal insulation layer is connected with the two-way steel mesh 4 and the foundation steel bars, and the inner wall surface layer 1, the thermal insulation layer 2, the two-way steel mesh 4 and the concrete layer 7 are provided with joints Rib 3, one or both of connecting bolts 9, the thermal insulation inner wall is also provided with reinforced concrete rib 17, built-in reinforced concrete rib main steel bar 6, concrete layer 7 sprayed as a whole behind the stirrup 5, as shown in Figure 2.

[0038] The roof panel is also connected by the insulation layer 2 and the inner wall surface layer 1, and a connecting rib 3 is arranged between the inner wall s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com