Energetic coordination complex based on azo tetrazole azotetrazole and use thereof

A technology of azotetrazole and complexes, applied in the field of energetic complexes, to achieve the effects of improved combustion performance, easy-to-obtain raw materials, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: PbATZ(phen) 2 ·3H 2 Synthesis of O

[0021] Ligand Preparation: Na 2 ATZ·5H 2 The synthetic reference method of O (Thiele J., JustusLiebigs Ann.Chem.1898,303,57): 0.5mol dry 5-aminotetrazole is dissolved in 500 milliliters of 10% NaOH solution, and the mixture is heated to 65°C in a water bath, After stirring for 30-40min, slowly add 65g KMnO 4 , and the reaction solution was stirred and reacted at 65° C. for 2 hours. Then add 500 ml of 95% ethanol under stirring and make the reaction solution boil for a few minutes while hot and filter to remove MnO 2 . The filtrate was cooled to give golden yellow needles. The product was washed with a small amount of absolute ethanol and dried in a desiccator at room temperature with a yield of 78%.

[0022] Preparation of Complexes: Metals and Ligands (ATZ 2 ), phen reacts in a molar ratio of (1:1:2):

[0023] pb 2+ +ATZ 2- +2phen+3H 2 O→Pb(ATZ)(phen) 2 (H 2 O) 3

[0024] Pb(NO 3 ) 2 (2mmol) and Na 2 A...

Embodiment 2

[0027] The metal complex Mn(ATZ)(phen) was prepared according to the preparation method described in Example 1 2 (H 2 O) 5 、Co(ATZ)(phen) 2 (H 2 O) 2 、Ni(ATZ)(phen) 2 (H 2 O) 2 、Cu(ATZ)(phen) 2 、Zn(ATZ)(phen) 2 (H 2 O) 2.5 、Pb(ATZ)(phen) 2 (H 2 O), Mn(ATZ)(bpy) 2 (H 2 O) 3 、Co(ATZ)(bpy) 2 (H 2 O) 7 、Ni(ATZ)(bpy) 2 , Cu(ATZ)(bpy), Zn(ATZ)(bpy)(H 2 O), Pb(ATZ)(bpy)(H 2 O) 2 , its metal ion composition content is measured by EDTA titration, C, H, N are measured by elemental analyzer, and the theoretical value is consistent with the calculated value.

Embodiment 3

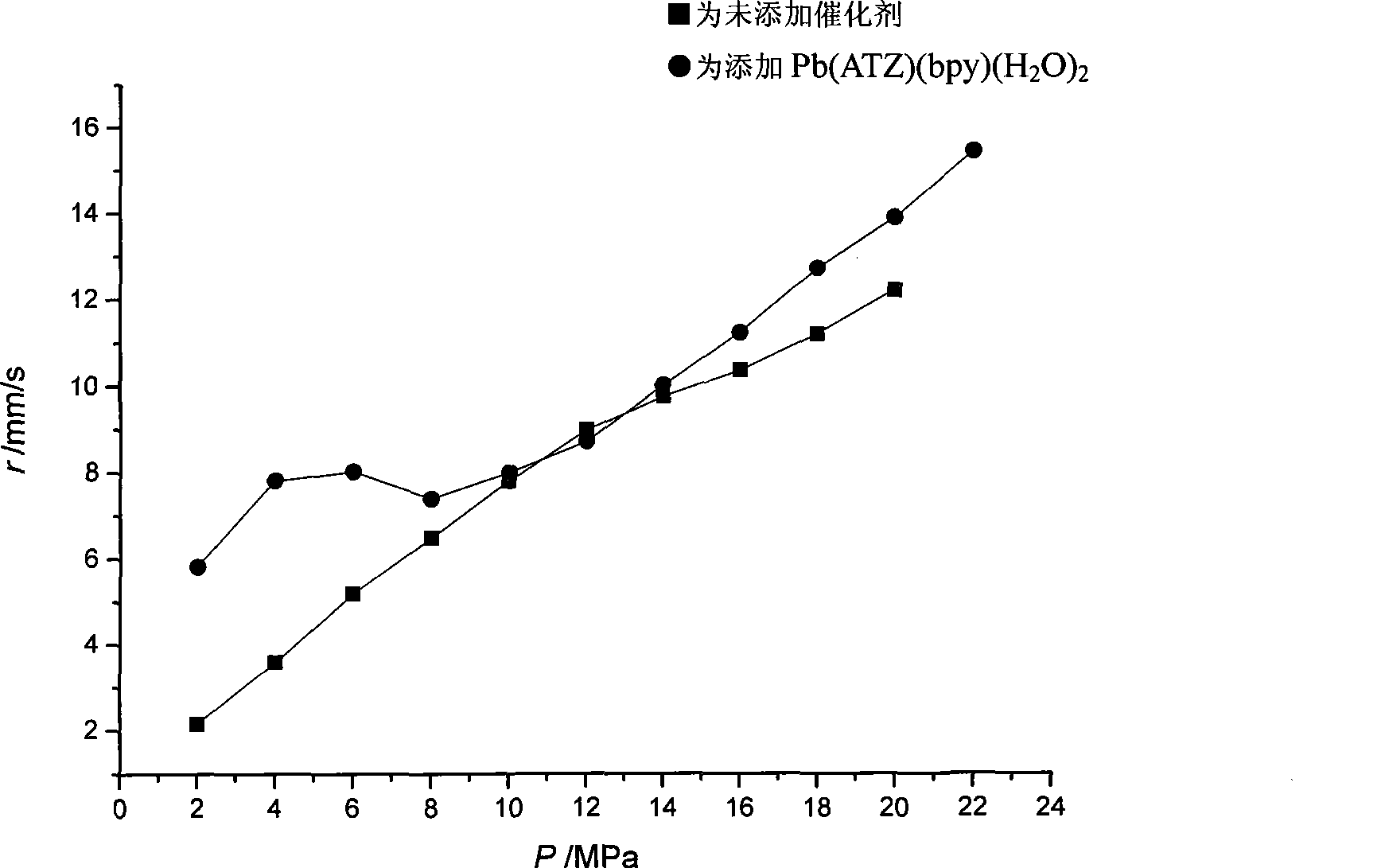

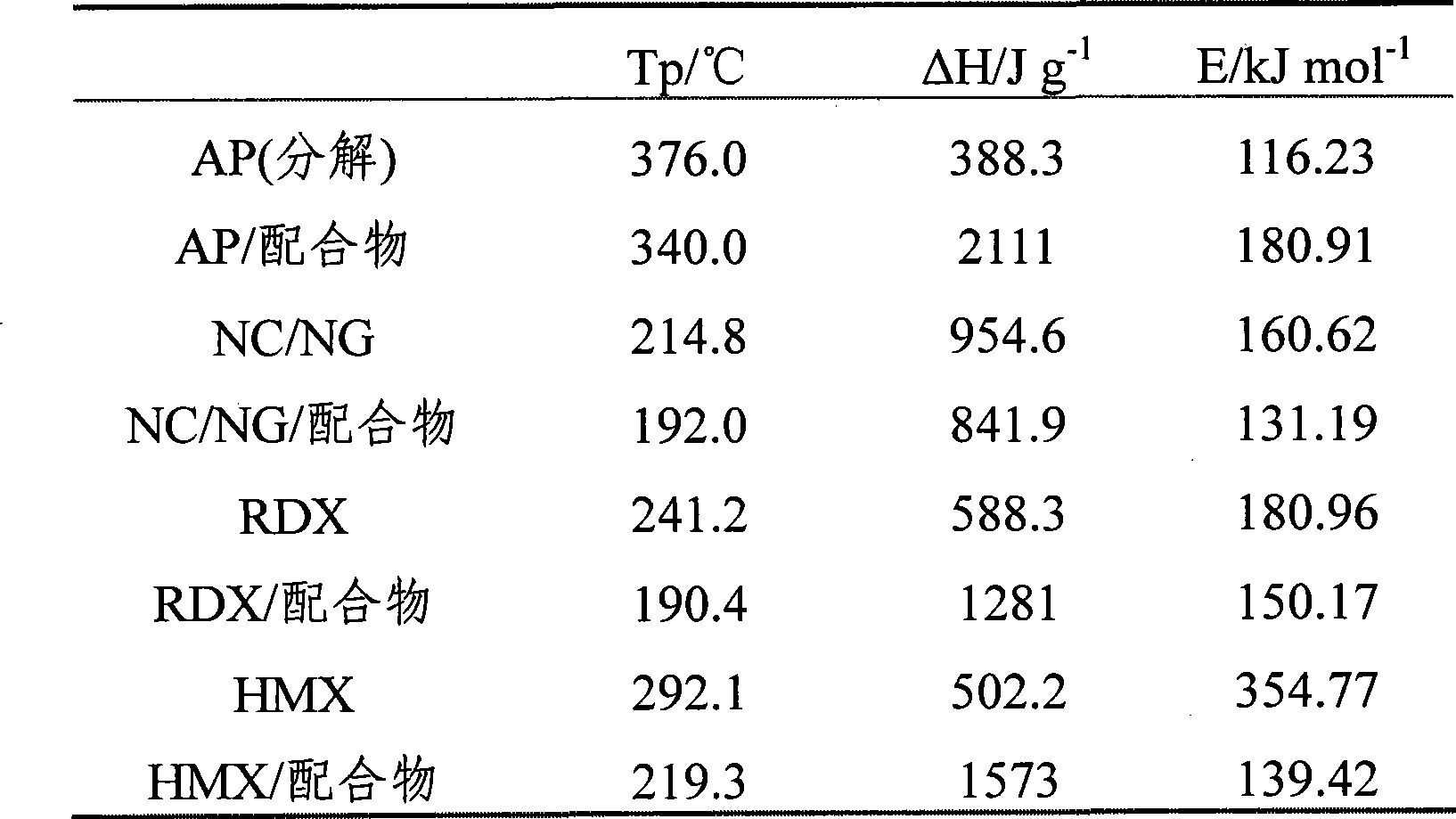

[0029] The main components of the propellant (RDX, HMX, AP and NC / NG) and the complex prepared in Example 1 and their binary mixed system were studied by DSC experiment. The substance and the single component are premixed at a mass ratio of 1:3, and the DSC experiment of the mixed component uses Al 2 o 3 The "sandwich sugar" method was used, and the activation energy was obtained by the Kissiger and Ozawa method through the DSC curves at four different heating rates. The results of the DSC thermogram analysis of each system are listed in Table 1.

[0030] Table 1 Characteristic parameters of thermal decomposition of mixtures of complexes and four single-component explosives

[0031]

[0032]The decomposition peak temperature is advanced to varying degrees. Except for NC / NG, the heat release of decomposition increases, and the heat of decomposition of AP increases the most. Except for AP, the activation energy of decomposition decreases. It is proved that the complex can p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com